Competitive Price for UPVC/PVC Cable Trunking Plant

Suzhou Midtech Industry Co., Ltd.- Product Type:PVC Profile

- Screw:Double-Screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Customized:Customized

Base Info

- Model NO.:MT400

- Profile:Cable Trunking Profile

- Motor:Weg

- SSR Relay:Celduc

- Screw/Barrel:Bimetallic

- Inverter:Schneider

- Contactor:Schneider

- Speed:4m,Min

- Punching Machine:Online Punching

- Mould:Double Cavities

- Haul off:240mm

- Transport Package:Standard Export Packing

- Specification:Customized

- Trademark:Midtech

- Origin:China

- HS Code:84772090

- Production Capacity:10 Sets, One Year

Description

Basic Info.

Model NO. MT400 Profile Cable Trunking Profile Motor Weg SSR Relay Celduc Screw/Barrel Bimetallic Inverter Schneider Contactor Schneider Speed 4m/Min Punching Machine Online Punching Mould Double Cavities Haul off 240mm Transport Package Standard Export Packing Specification Customized Trademark Midtech Origin China HS Code 84772090 Production Capacity 10 Sets/ One YearProduct Description

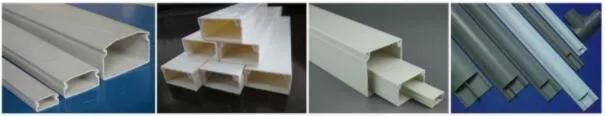

PVC/Plastic cable trunkings profiles Extruder/Making machines

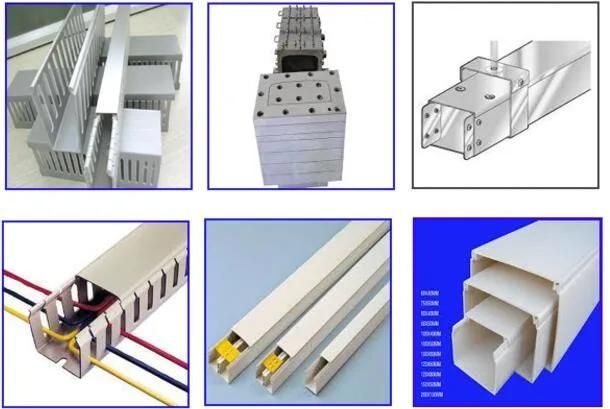

This unit mainly includes accurate extruder, die(mould), vacuum calibration table, haul-off, cutter and etc. Main machine and haul-off adopt imported prequency inverter, stainless steel calibrator, traction speed steady, size accu racy high, cutter adopts PLC control, and cutting length can be set at random.

Trunking production line/pvc trunking

PVC Cable Trunking Production Line (Extrusion Machine)

1)high-speed extrusion

2)competitive price

3)PVC trunking production

PVC Cable Trunking Production Line (Extrusion Machine)

PVC cable trunking profile production line processing:

Raw material + additive → mixing → conical twin-screw extruder → profile extrusion mould → cool molding die → vacuum calibration support → belt haul-off → cutter → rack → finished product

|