Plastic PE/PP/PVC/ABS/HIPS/Spc/Polycarbonate/TPE Wall Panel/Floor/Imitation Marble/Foaming ...

Wuxi Boyu Plastic Machinery Co., Ltd.- After-sales Service:24*7

- Warranty:1 Year for Main Mechanical Part

- Type:Sheet Extruder

- Plastic Processed:PVC,WPC,Spc,PP

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

Base Info

- Model NO.:SJSZ180

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Voltage:220-415V , 50-60Hz 3 Phase

- Power:485-750kw Per Line

- Production Line Layout:60m (L) * 5m (W) * 8m (H)

- Calender:Five Roller

- Deliver Time:45 Days

- Plank Thickness:2-9mm

- T-Die:1050,1350

- Online Embossing:Better Than 95%

- Capacity:100t,24h

- Transport Package:PE Wrapping Film, Fumigating Wooden Cases.

- Specification:CE, SGS, UL, TUV, CSA, ISO

- Trademark:BOYU

- Origin:Wuxi, Jiangsu, China

- HS Code:8477209000

- Production Capacity:120 Sets Per Year

Description

Basic Info.

Model NO. SJSZ180 Assembly Structure Integral Type Extruder Screw Twin-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Voltage 220-415V / 50-60Hz 3 Phase Power 485-750kw Per Line Production Line Layout 60m (L) * 5m (W) * 8m (H) Calender Five Roller Deliver Time 45 Days Plank Thickness 2-9mm T-Die 1050/1350 Online Embossing Better Than 95% Capacity 100t/24h Transport Package PE Wrapping Film, Fumigating Wooden Cases. Specification CE, SGS, UL, TUV, CSA, ISO Trademark BOYU Origin Wuxi, Jiangsu, China HS Code 8477209000 Production Capacity 120 Sets Per YearProduct Description

The launch of a InnovationProven technology with a new product concept and an attractive price-performance ratio

As SPC flooring equipment inventor, we Boyu Extruder are always keeping moving on new research and development. At the beginning of 2021, we have produced the new super output performance extruder SJSZ180, and firstly provided 6 sets to our good partnership customer. After several months successful operation, we now are in great confidence to launch these new productivity-enhancing to all of our customers and help them enjoy more BENEFITS.

- SAVE PLANT SPACE

- SAVE LABOUR COST

- SAVE ENERGY CHARGE

- SAVE SCREW COST

| Extruder Model | Capacity/24H | Capacity/H | Linear Speed | Power |

| SJSZ-180 | 100-120T | 4300-5000KG | 5-9m/min | 450KW |

| No. | Items | Data |

| 01 | Operation Conditions | 380V/3 phases/50Hz, DC24V. (customize) |

| 02 | Raw Material | PVC powder, calcium carbonate, stabilizer, lubricant, small materials |

| 03 | Main material proportion | PVC: CACO3= 1:3 |

| 04 | Product specifications | Width:1050/1350mm, Thickness:2-9mm |

| 05 | Machine Fabrication Certificate | CE/UL/SGS/CSA |

| 06 | Electric components certificate | CE/UL/SGS/CSA |

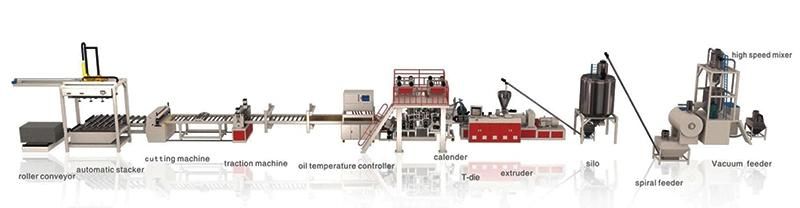

III. 180 Conical Twin Screw Spc Flooring Production Line 180 SPC floor extrusion line Equipment List and layou

Extruder → T-die → Five Roller Calender → Oil temperature controller → Traction Machine → Cutting Machine → Automatic Flipper & Stacker

IV. 180 Conical Twin Screw Spc Flooring Production Line 180 SPC floor extrusion line Patents Certificates

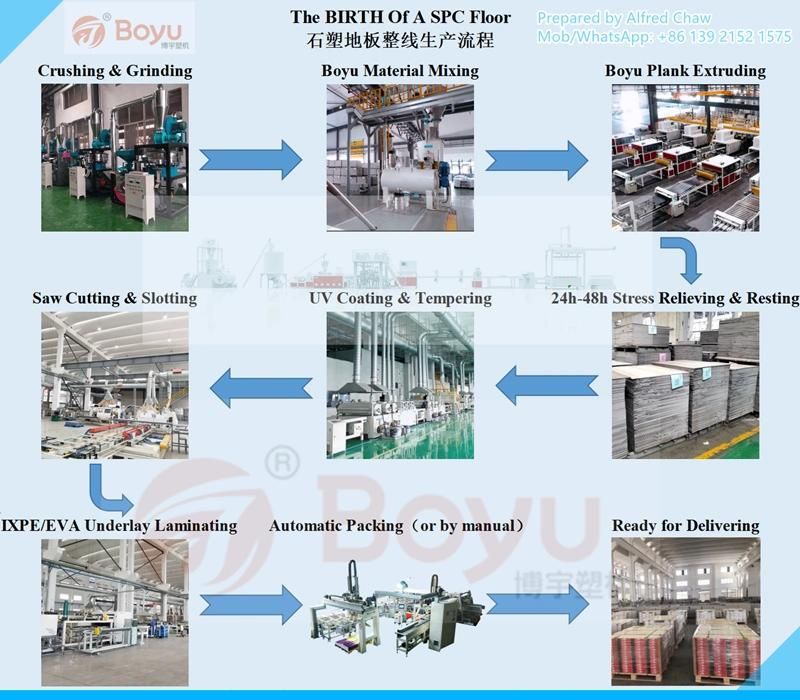

V. 180 Conical Twin Screw Spc Flooring Production Line 180 SPC floor extrusion line Whole Production Flow

Material mixing → Extruder → Calender→ Cut-to-length →Stacking →UV coating →Saw cutting →

Slick slotting →Backing limitation →QC inspection → Packing

VI. Shipping

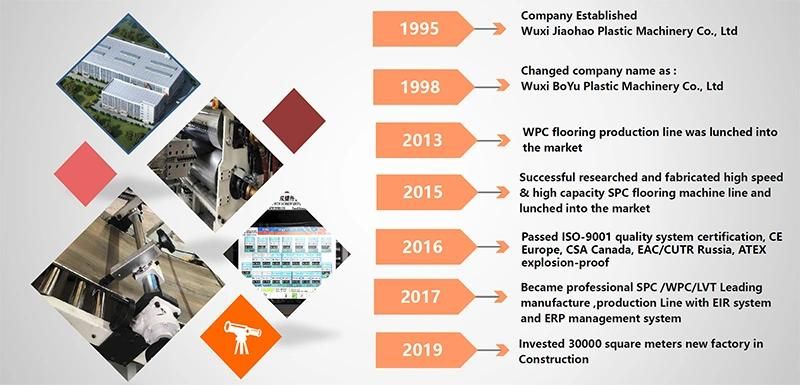

VII.Boyu Company Profile

VII.Boyu Company Profile

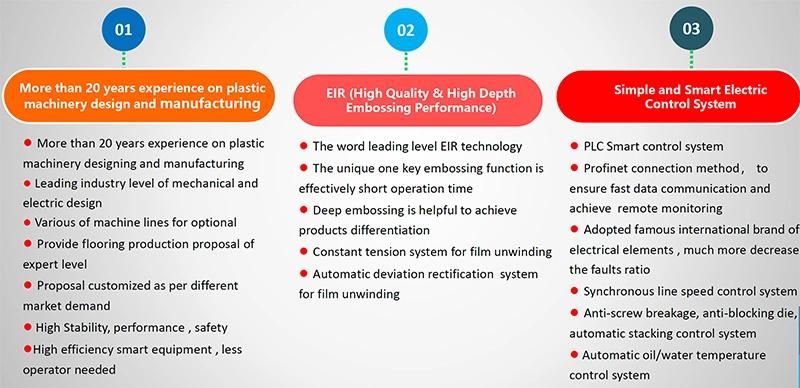

VIII. Advantages of BOYU Production Machine Line

IX. BOYU Services

X. Project Case

X. Project Case