Three-Roller Plastic Sheet Extrusion Machine Double Station Rewinding Plastic Sheet ...

Zhejiang Hongyin Machinery Co., Ltd.- After-sales Service:Video Technical Support, Free Spare Parts

- Warranty:1 Year

- Type:Sheet Extruder

- Plastic Processed:PP,PS,HIPS

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

Base Info

- Model NO.:DB-110-850

- Assembly Structure:Integral Type Extruder

- Screw:Single-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Model:dB-110-850

- Suitable Material:PP PS HIPS

- Sheet Thickness:0.2-2.0mm

- Sheet Precision:0.015-0.01mm

- Effective Width:400-700

- Capacity:160-200kg,Hr

- Layer:1

- Rated Output:80kw

- Dimension:12X1.6X2.0m

- Transport Package:Wooden or Film

- Specification:CE

- Trademark:HongYin

- Origin:Zhejiang China

- Production Capacity:10set,Mounth

Description

Basic Info.

Model NO. DB-110-850 Assembly Structure Integral Type Extruder Screw Single-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Model dB-110-850 Suitable Material PP PS HIPS Sheet Thickness 0.2-2.0mm Sheet Precision 0.015-0.01mm Effective Width 400-700 Capacity 160-200kg/Hr Layer 1 Rated Output 80kw Dimension 12X1.6X2.0m Transport Package Wooden or Film Specification CE Trademark HongYin Origin Zhejiang China Production Capacity 10set/MounthProduct Description

Three-roller Plastic Sheet Extrusion Machine Double Station Rewinding Plastic Sheet Forming Machine Machine Description:

Machine Description:This machine is designed to produce plastic sheets for thermoforming/vacuum forming purposes or stationery use, which is composed of 7 parts: extruder part, filter part, die-head part, 3 rollers part, traction part, winding part, and side trimming part.

The machine body is made of reinforced integral steel, which makes the machine run stably and smoothly.

Applicable Materials:

It is used to produce various plastic sheets of PS (polystyrene) or PP/HIPS (polypropylene), which can be widely used to produce plastic cups, plastic bowls, plastic containers, and boxes, etc.

Main parts introductions:

Gear reduction unit:

Adopts high-quality GUOMAO gear reducer.

The gear reducer is driven by helical gear on the hard tooth surface. The gear material is of high-quality 20CrMoTi Forging parts, high-frequency treatment, hardness hrc54-58 (tooth surface grinding).

Oven Heating:

Oven Heating:a. Adopts 7 rows Stainless steel heating ring

b. Power: AC 220V, 5OHZ

Barrel & Screw: (Zhoushan)

Barrel & Screw: (Zhoushan)Barrel & Screw material: 38CrMoALA

Mesh filter:

Mesh filter:It is used to filter impurities in the extrusion process.

Die head:

Die head: Mold material adopts 40 Cr forge

The die heating area has 5 zones

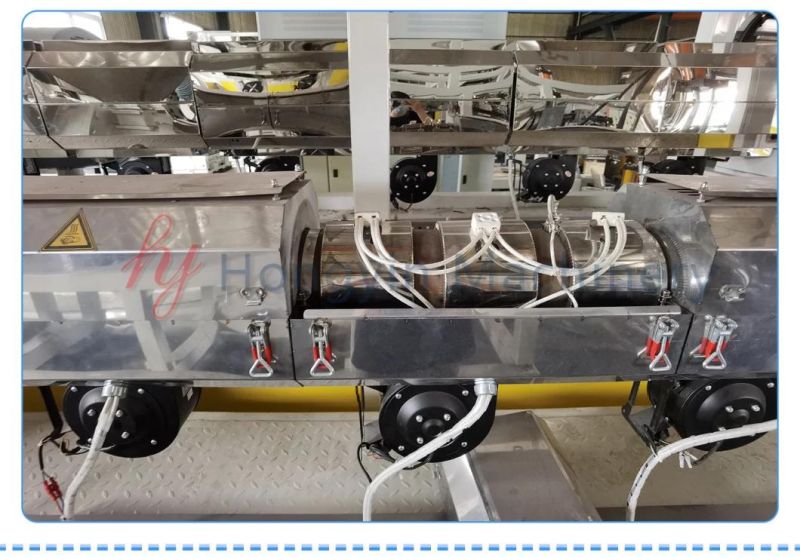

Three rollers of calendar:

Three rollers of calendar:1. Transmission mode: Three-roller independent motor control, each motors control by inverter. (Servo motor control is optional).

2. Roller adjusts way: Control by turbine and worm synchronous.

3. Three-rollers circulating water cooling.

4. Inner screw-type roller, ensure cooling effectively.

5. The roller is processed by medium frequency. The surface hardness of the roller is HRc58 or above, and the quenching depth is 3-5mm.

6. The bearing pedestal is made of 45# steel. The structure is divided into sections for easy bearing replacement and maintenance.

Material traction:

Material traction:There are two options for material traction. If the machine area needs to be smaller, bridge traction can be used.

Edge cutting device:

Edge cutting device: Two cutting knives can be used on both sides to effectively remove the edge material and cut the sheet material to reach the required width.

Wasted material rewinding or crushing(Optional):

Wasted material rewinding or crushing(Optional): Finished Sheet Rewinding:

Finished Sheet Rewinding:

About Ruian Hongyin Machinery Co., Ltd Service.

1. Pre-sales Service

Hongyin MACHINERY has a specialized and efficiency working team. If you are new on the plastic forming machine area, we are glad to give you specialized suggestion of the whole work.

2. Shipping Service

Hongyin MACHINERY has a specialized and independent department to arrange the shipment. We will prepare all the necessary documents so as to arrange the delivery smoothly.

We cooperate with the most famous shipping company in China, they could provide the best and economic shipping ways to the destination.

3. Installation Services

Installation Services are available with all Hongyin Company machines. We could dispatch technician to the Buyer's factory for installation and preparation of the machines.

The buyer needs to supply the round trip tickets, food, hotel cost and daily salary.

4. Clients Training Services

The buyer could also send your own technician come to Hongyin factory to learn how to operate machines. Our technician will teach and train the learners hand by hand till he can operate machine by himself.

5. After Sales Service

Hongyin Company machines guarantee time is one year.

Many easy broken spare parts will be prepared in the tool box together with machines.

If you are interested in our machine, please feel free and contact me.

Ms. Irena