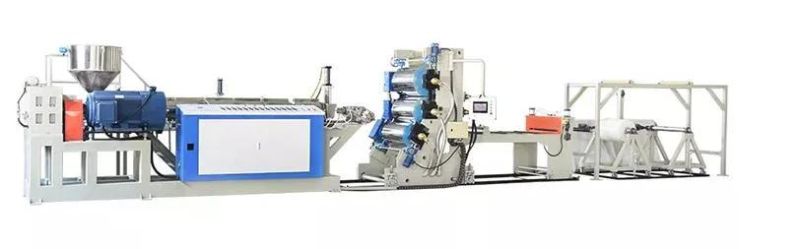

Single Layer Plastic Sheet Extruding Machine

Shantou Feiteng Trading Co., Ltd.- After-sales Service:Training How to Install and Use The Machine

- Warranty:1 Year

- Type:Sheet Extruder

- Plastic Processed:PP, PP,PS

- Product Type:Extrusion Molding Machine

- Feeding Mode:Multiple Feed

Base Info

- Model NO.:High Tansparent Single Layer Extruding machine-1

- Assembly Structure:Separate Type Extruder

- Screw:Single-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Core Components:Motor,PLC

- Thickness Accuracy:<=+-0.015mm

- Link Speed:3~20m,Min

- Layers:1 Layer

- Screw Speed (Rpm):20rpm

- Sheet Thickness:0.3~2.5mm

- Width of Plastic Sheet:Less or Equel750

- Max Diameter:800mm

- Voltage:380V

- Power (Kw):170

- Transport Package:Film and Wood Carton. by Container and by Ship

- Specification:11000*1200*2200mm

- Trademark:Feiteng

- Origin:Guangdong, China

- HS Code:8477209000

- Production Capacity:100 Sets Per Year

Description

Basic Info.

Model NO. High Tansparent Single Layer Extruding machine-1 Assembly Structure Separate Type Extruder Screw Single-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Core Components Motor,PLC Thickness Accuracy <=+-0.015mm Link Speed 3~20m/Min Layers 1 Layer Screw Speed (Rpm) 20rpm Sheet Thickness 0.3~2.5mm Width of Plastic Sheet Less or Equel750 Max Diameter 800mm Voltage 380V Power (Kw) 170 Transport Package Film and Wood Carton. by Container and by Ship Specification 11000*1200*2200mm Trademark Feiteng Origin Guangdong, China HS Code 8477209000 Production Capacity 100 Sets Per YearProduct Description

Main Performance And Structure Features:

Can be make the Single plastic sheet of PP, PS materials according to difference use and features of products, The multilayer sheet can be make the disposable drink cup. jelly cup, bowl, takeaway food container, packing box and so on.

1.The extruder screw has the advantages of large length to diameter ratio, good plasticizing effect, uniform thickness of diaphragm, uniform flow rate and so on

2.The advanced electric fast changing network device has the advantages of convenient operation, good performance and increasing production efficiency.

3.The super mirror roller is horizontal, vertical or 45 degree tilted, and it can be lifted freely. The surface temperature of the roller is uniform, making the sheet bright and clean, even and thick.

4.The roller is adjusted by the turbine. The operation is convenient and the precision is high.

5.The sheet rewinding device adopts double station hydraulic winding, electric winding or air lift shaft winding.

6.Three roller adopts high quality gear reducer, which can be selected with variable frequency motor to control the control of servo motor