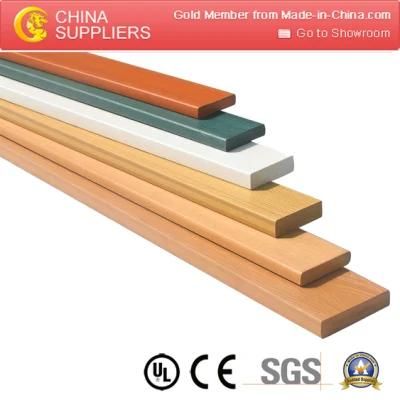

Top Quality PS Decoration Profile Extrusion Machine

GPM Machinery (Shanghai) Co., Ltd.- Product Type:PS

- Screw:Single-Screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008, UL, QS, GMP

- Customized:Customized

Base Info

- Model NO.:GYF

- Output:250- 450kg,H

- Product Name:PS Decoration Profile Extrusion Machine

- Other Name:PS Decoration Profile Making Machine

- Transport Package:PE Film Winding Wrapping

- Specification:37KW-110KW

- Trademark:GPM

- Origin:Shanghai

- HS Code:8477209000

- Production Capacity:500units,Month

Description

SPECIFICATIONS FOR HIGH EFFICIENCY PS FOAMED MITATE WOOD EXTRUSION LINEModel GYF-PS1 GYF-PS2 GYF-PS3 GYF-PS4 Extruder GW65 GW75 GW90 GW120 Co-extruder GW35 GW45 GW45 GW45 Products Width 3inch 4inch 5inch 6-8inch Speed 1-3m/min 1-3m/min 1-3m/min 1-3m/min

XQY180 Haul-off Unit

Quantity of caterpillar: 2 sets

Film-covering device: Clamped by cylinders. Film are covered on both surface.

Haul-off motor: 1.5kw x 2 sets

Controlled by imported frequency converter-Imported brand

Effective width of caterpillar: 180mm

Haul-off speed 0.5~4.6m/min

XQG180Cutter

Power of motor: 1.5 KW

Max. Cutting width: 108mm Max. Cutting height:120mm

Power of sucking-dust-fan: 0.75 KW

Cutting saw: Alloy steel, specially for cutting PVC profile - O.D. 400mm

Rack moved by reduction motor and knife lifting and clamping moved by pneumatic

Manual or automatic cutting type

With meter-calculating device

XDX180 Vacuum calibration table

Calibration tanks and basin are made of stainless steel

Table length: 3000mm

Table width: 1100mm

Distance between aluminum track: 320mm

Vacuum pump power and quantity: 5.5 KW x1. (Water should be exhausted in case of frozen)

Water pump power and quantity: 4kw x 1set

Quantity of air nozzle: 16 pcs (marked in yellow)

Quantity of water nozzle: 16 pcs (marked in blue)

Mould supporter: casting aluminum bar with T shaped slot for fixing mould tool. Supporting rack and water pipe are integrated, which is made of stainless steel tube.

Installation of air and water nozzle: Air nozzles are installed on guard plate and water nozzles are installed on supporting rack.

Electric controlling cabinet and panel with waterproof covering

With air fan device (0.75kw) for drying water on the product surface

Lifting device for calibration: calibration and haul-off are connected by lead screw bolt with deceleration motor of 0.75kw.

Fitted with a device for vertical adjustment

Fitted with a device for horizontal adjustment and can be adjusted by hand

For choosing the proper machine and saving your time, please read these bellow guides carefully

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the width and thickness of sheet(mm)?

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.

if you are interested in this machine ,please contact me:

mob : +86 13915723896 ( or +86 13817556740 )

Jeremy He

XQY180 Haul-off Unit

Quantity of caterpillar: 2 sets

Film-covering device: Clamped by cylinders. Film are covered on both surface.

Haul-off motor: 1.5kw x 2 sets

Controlled by imported frequency converter-Imported brand

Effective width of caterpillar: 180mm

Haul-off speed 0.5~4.6m/min

XQG180Cutter

Power of motor: 1.5 KW

Max. Cutting width: 108mm Max. Cutting height:120mm

Power of sucking-dust-fan: 0.75 KW

Cutting saw: Alloy steel, specially for cutting PVC profile - O.D. 400mm

Rack moved by reduction motor and knife lifting and clamping moved by pneumatic

Manual or automatic cutting type

With meter-calculating device

XDX180 Vacuum calibration table

Calibration tanks and basin are made of stainless steel

Table length: 3000mm

Table width: 1100mm

Distance between aluminum track: 320mm

Vacuum pump power and quantity: 5.5 KW x1. (Water should be exhausted in case of frozen)

Water pump power and quantity: 4kw x 1set

Quantity of air nozzle: 16 pcs (marked in yellow)

Quantity of water nozzle: 16 pcs (marked in blue)

Mould supporter: casting aluminum bar with T shaped slot for fixing mould tool. Supporting rack and water pipe are integrated, which is made of stainless steel tube.

Installation of air and water nozzle: Air nozzles are installed on guard plate and water nozzles are installed on supporting rack.

Electric controlling cabinet and panel with waterproof covering

With air fan device (0.75kw) for drying water on the product surface

Lifting device for calibration: calibration and haul-off are connected by lead screw bolt with deceleration motor of 0.75kw.

Fitted with a device for vertical adjustment

Fitted with a device for horizontal adjustment and can be adjusted by hand

For choosing the proper machine and saving your time, please read these bellow guides carefully

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the width and thickness of sheet(mm)?

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.

if you are interested in this machine ,please contact me:

mob : +86 13915723896 ( or +86 13817556740 )

Jeremy He