Plastic Extrusion Companies Specializing in Custom UPVC/PVC Plastic Door Profile

Hebei Shuangda Rubber Machinery Co., Ltd.- After-sales Service:One Year

- Warranty:One Year

- Type:Piston Extruder

- Plastic Processed:PVC

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

Base Info

- Assembly Structure:Integral Type Extruder

- Screw:Single-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Non Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Transport Package:Wooden Package

- Specification:3600*1200*1600

- Trademark:Shuangda

- Origin:China

- Production Capacity:20 Sets , Month

Description

Basic Info.

Assembly Structure Integral Type Extruder Screw Single-Screw Engagement System Full Intermeshing Screw Channel Structure Non Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Transport Package Wooden Package Specification 3600*1200*1600 Trademark Shuangda Origin China Production Capacity 20 Sets / MonthProduct Description

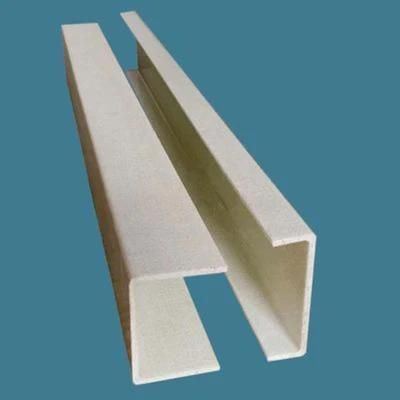

Plastic Production Extruding Production LineOverview: Production line: single screw extruder + mold + sink + traction +winder, Mold type: different mold do all kinds of shapes PVC sealing products Application: doors and windows, cars, containers, electric vehicles, refrigerators, sterilization cabinets and other sealing products.

Detailed introduction: The plastic sealing strip production line must go through two processes in production, one process is granulation. Granulation requires a crusher, kneader, pelletizer and pelletizer.

Extrusion process (soft strip) 1. The plastic particles are directly put into the extruder for extrusion production, 2. Cooled directly after forming the mold, 3. Then it can be produced after pulling the strip. If the extruded sliver does not meet the size required by our 4. or the raw material formula is not mastered, you can directly reprocess the made sliver through the crushing link.

Extrusion process rigid strip extrusion -cooling-traction-cutting about cooling principe here is more detailed introduction Sizing vacuum cooling table our enginner: hard material happened water easy deforming situation 1.cooling in Sizing mold in the water tank: vacuum pump will exhausted inside air of molds, cooling the molds and Sizing the profile. because inside molds will have a shape adhesive the profile and provide his support power, so will not happened deforming situation. 2. cooling in the water tank inside of water the profile will lack the support power/mold wall, so there will have deforming machine.