-

Double Station Jerry Can 5L Extrusion Blow Molding Machine

SummarizeHigh intension, rigidity, center mold locking, stable mould opening and advanced clamping systemClamping force270 KNDistance between platens450~950mmMould template680× 660Mould materialS50C/Aluminium with beryllium copper

-

Semi Automatic Energy Saving Jerry Can Blowing Machine

SummarizeHigh intension, rigidity, center mold locking, stable mould opening and advanced clamping systemClamping force270 KNDistance between platens450~950mmMould template680× 660Mould materialS50C/Aluminium with beryllium copper

-

Servo Motor Jerry Can Blowing Shaping Machine

SummarizeHigh intension, rigidity, center mold locking, stable mould opening and advanced clamping systemClamping force270 KNDistance between platens450~950mmMould template680× 660Mould materialS50C/Aluminium with beryllium copper

-

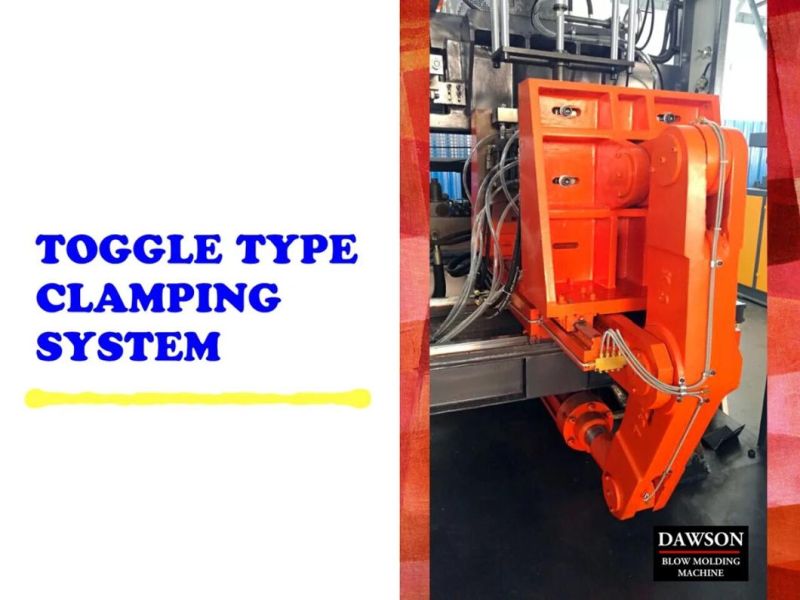

Toggle Type Blowing Moulding Machine for Jerry Can

SummarizeHigh intension, rigidity, center mold locking, stable mould opening and advanced clamping systemClamping force270 KNDistance between platens450~950mmMould template680× 660Mould materialS50C/Aluminium with beryllium copper

-

Semi Automatic 12L Jerry Can Making Machine

SummarizeHigh intension, rigidity, center mold locking, stable mould opening and advanced clamping systemClamping force270 KNDistance between platens450~950mmMould template680× 660Mould materialS50C/Aluminium with beryllium copper

-

12L Single Station Jerry Can Blowing Machine

SummarizeHigh intension, rigidity, center mold locking, stable mould opening and advanced clamping systemClamping force270 KNDistance between platens450~950mmMould template680× 660Mould materialS50C/Aluminium with beryllium copper

-

Servo Motor 5L Jerry Cans Blowing Shaping Machine

SummarizeHigh intension, rigidity, center mold locking, stable mould opening and advanced clamping systemClamping force270 KNDistance between platens450~950mmMould template680× 660Mould materialS50C/Aluminium with beryllium copper

-

High Speed 12L Jerry Can Extrusion Blow Molding Machine

SummarizeHigh intension, rigidity, center mold locking, stable mould opening and advanced clamping systemClamping force270 KNDistance between platens450~950mmMould template680× 660Mould materialS50C/Aluminium with beryllium copper