Co-Rotating Twin Screw Extruder Machine Compound PE PP Filler Masterbatch

Zhangjiagang Jorbin Machinery Co., Ltd.- After-sales Service:24 Hours

- Warranty:1 Year

- Type:Granulation Extruder

- Plastic Processed:PA PC Pek

- Product Type:Granulating Extruder

- Feeding Mode:Multiple Feed

Base Info

- Model NO.:TSSK75

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Capacity:50-600kg,H

- Screw and Barrel:38CrMoAl, Nitrogen, Bimetallic

- Application:Pet Bottle Recycling

- Degassing:Roots Vacuum

- Pelletizing Way:Pull Strap(Like Noodles)

- Delivery Time:45 Working Days

- Extruder:Co-Rotating Twin Extruder

- Cooling Way:by Water

- Heater:Cost Al or Cost Copper

- Ld:36:1, 40:1,44:1,48:1

- Guarantee:1 Year

- Auto:Full Auto

- Vacuum:Roots or Bipolar

- Heat Way:by Electric

- Dry:Crystallization Drying

- Transport Package:Film Packing and Wood Base or Wood Case

- Specification:pellets size Φ 2.5*3mm

- Trademark:JORBIN

- Origin:Zhangjiagang City

- HS Code:84772010

- Production Capacity:10sets,Year

Description

Model

TSSK20

TSSK30

TSSK35

TSSK50

TSSK65

TSSK72

TSSK92

Screw diameter(mm)

21.7

30

35.6

50.5

62.4

71.2

91

Rotary speed(rpm)

600

400

400/600

500/600

400/500

400/500

400/500

Main motor power(kw)

4

11

11/15

37/45

55/75

90/110

220/250

L/D

32-40

28-48

32-48

32-48

32-48

32-48

32-40

Capacity(kg/h)

2-10

5-30

10-80

20-150

100-300

300-600

600-1000

Machine line

Machine parameter

1.Screw diameter:Ф71.2 2.Internal diameter of barrel:Ф71.8

3.Center distance:60 4.L/D:41:1

5.Motor power:90kW 6.Rotary speed:500rpm

7.Feeding method: single-screw feeder

8.Cooling method:Force water cooling

9.Lubrication way:Oil dipping

10.Heating method:cast aluminum and cast copper , customer can choose by themselves

11.Palletizing method: cooling pulls strip granulation

12.Diameter of the pellet:φ2

13.Speed controller:Britain EURO digital speed governor

Rotary charger send the material into the feeder and then the feeder feed the Raw material into the extruder equally and smoothly.

Two side feeder to feed glass or other additives into the extruder. Vacuum degassing on the extruder,because there are two side feeder on the extruder, so there no need to use natural degassing, one vacuum degassing is enough.

Vacuum degassing on the extruder,because there are two side feeder on the extruder, so there no need to use natural degassing, one vacuum degassing is enough. Screen changer,The material come out from the die(pull trap like noodles pelletizing way, PET must use this pelletizing way. PC, KPE ABS are also need pull strap pelletizing way. )

Screen changer,The material come out from the die(pull trap like noodles pelletizing way, PET must use this pelletizing way. PC, KPE ABS are also need pull strap pelletizing way. )

Materil come out from the die

Cooling for the screw( water controlled by electric valves)

Screw elements, barral and the core of the machine

Gale(dry the material)Pelletizer(cutter the strap into pellets)

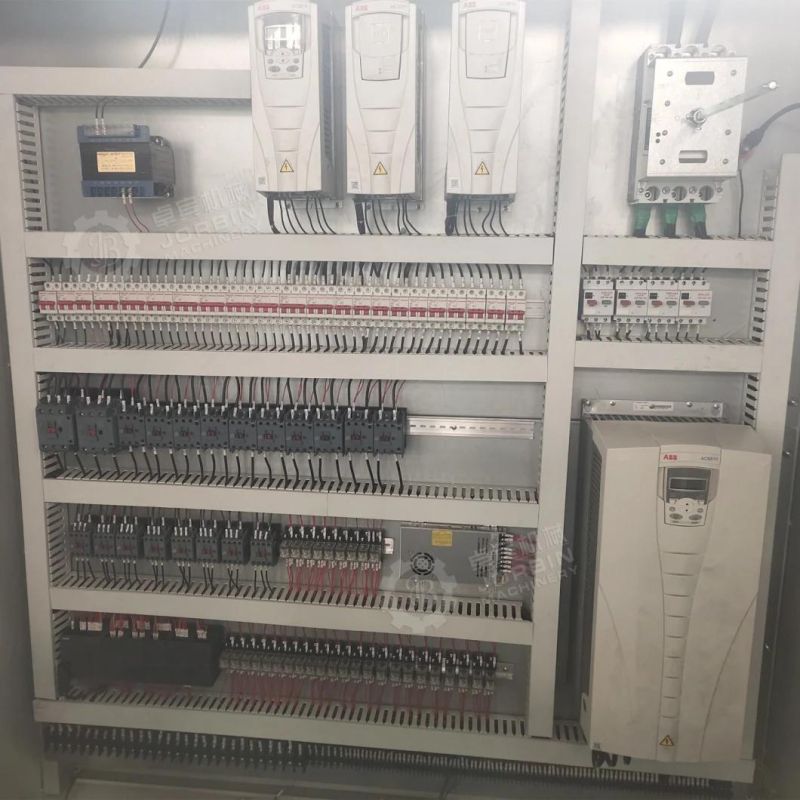

Electric cabinet inside And we also can use PLC screen touch to control the whole line of the machine.

And we also can use PLC screen touch to control the whole line of the machine.

If you need more details of this kind of machine kindly contact me, I can send you more detail photoes and vedios.

1. We supply below necessary documents with the machine:

- Machine layout

- Electricity diagram

- Machine certificate

- General manual book/maintenance book

2. We provides one-year quality guarantee. During this period, if the machine's malfunction is approved to be our responsibility, we will send the broken spare parts to you with DHL courier or other way within 7 workdays after receiving the complainant. And send the technicians to the buyer's factory for maintaining. All charges are in our account.

3. After one year guarantee, If you need we can provides payable spare parts and technician's VISITING maintenance, and any broken spares we can send you soon as possible.

4. We trust that our quotation meets with your requirements and we will gladly furnish you with further information.