Plastic Pet Bottle Washing and Recycling Line

Suzhou Midtech Industry Co., Ltd.- Material Processed:Plastic Bottle

- Plastic Type:PET

- Screw:Single-Screw

- Automation:Automation

- Computerized:Computerized

- Certification:UL, ISO9001:2008

Base Info

- Model NO.:MT2000

- Pet Bottle Recycling Line:2000kg,Hr

- Transport Package:Wood

- Specification:sgs

- Trademark:middle tech

- Origin:Zhangjiagang City

- HS Code:84778000

- Production Capacity:2000kg,Hr

Description

Basic Info.

Model NO. MT2000 Pet Bottle Recycling Line 2000kg/Hr Transport Package Wood Specification sgs Trademark middle tech Origin Zhangjiagang City HS Code 84778000 Production Capacity 2000kg/HrProduct Description

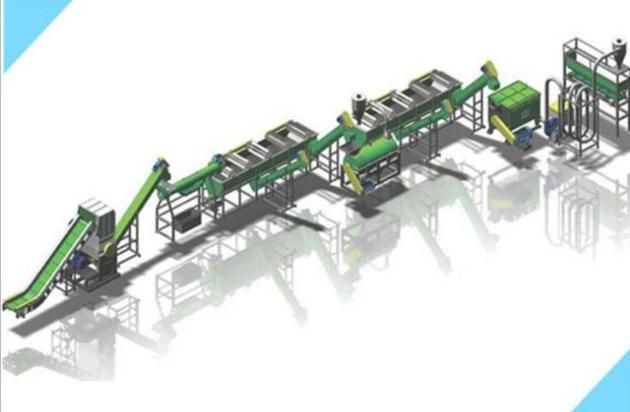

PET Bottles Washing Plant

Our Universal Plastic Washing Plants are high performance recycling systems for the

recovery of rigid or flexible plastics from derived from various sources.

It was designed for recycling of post consumer PET bottles including labels and caps.

These systems produce uniform size PET flakes with high purity and low moisture level.

Capacity:

300kg/hr, 500kg/hr, 1000kg/hr, 1500kg/hr, 2000kg/hr, 3000kg/hr

Our products

Debaling------Label Scrapping------ Label Separation---------Bottle Pre-washing-------- Manual Sorting and Metal Detecting-----Wet Grinding------- Gravity Separation------- Hot-washing ----Continuous Rinsing-------- Drying-------- Dust Removing------ Packing

| Description | Characteristic |

PET Containers | One-way bottles |

Colors Fraction | PET bottles should be pre-sorted by color. If the percentage of color bottles is higher than 30%, we suggest customer to install the automatic color bottle sorting machine to achieve efficiency. |

Base Cups | Included, if any, and should be PP or PE plastic. |

Labels (shrunk or glued) | The production line is designed for removing label mechanically. All type of labels will be removed by mechanical action. It includes paper, BOPP, PET, PVC, etc. |

Caps | PP, HDPE |

Caps seals | EVA, PP ( floatable material ) PVC or rubber seals are not separable. |

Glue | Hot melt, water borne. |

Contamination | Mixed with the bottles could be present contaminations coming from the collection and storage of the postconsumer bottles or made by consumer. These contaminations include mud, sand, soil, glass, organics, paper, residual liquid, etc. Total contamination content should not exceed 10%. |

Total Non-PET Containers | Non-PET containers max 2% of which |

PVC Container | 0.5 -1% max |

Polyolefins Container | 3 % max. It will only affect the output volume but not quality of end product. |

Wrong PET Colors and Opaque | 1-2% max |

| Glass and Ceramic (metals excluded) | 0.5 -1% max |

Magnetic Metals | 0.5 - 1% max |

| Aluminum and Non Magnetic Metals | 0.5 - 1% max All kind of metal will be separated before crushing |