PE Film Agglomerator Granulating Pelletizing Extruder Machine

Zhangjiagang Kwell Machinery Co., Ltd.- Raw Material:LLDPE

- Screw:Single-Screw

- Inverter:Inverter

- Electromagnetic Heater:Electromagnetic Heater

- Automation:Automatic

- Computerized:Computerized

Base Info

- Model NO.:SJ85, SJ100, SJ120, SJ130, SJ150, SJ160, SJ180

- Customized:Customized

- Certification:CE, ISO9001:2008, QS, UL, GMP

- Condition:New

- Plastic Type:HDPE,LDPE,EVA,PP,BOPP,ABS,PS,HIPS,PA,PC,PU,EPS

- Extruder Capacity:180-1000kg,H

- Delivery Period:35-45work Days

- Motor Brand:Siemens

- Electrical Apparatus Element:Schneider,Siemens

- Blade Material:SKD-11,DC53

- Warranty Period:5 Years

- Screw Material:Bimetallic

- Spare Parts:Supply for Free Forever

- Frequency Converter:ABB

- Transport Package:Seaworthy Packing for PE Film Pelletizing Machine

- Specification:Top Feed(PE Film Compactor Granulating Machine)

- Trademark:KWELL

- Origin:China

- HS Code:84772010

- Production Capacity:10sets,Month

Description

Basic Info.

Model NO. SJ85, SJ100, SJ120, SJ130, SJ150, SJ160, SJ180 Customized Customized Certification CE, ISO9001:2008, QS, UL, GMP Condition New Plastic Type HDPE/LDPE/EVA/PP/BOPP/ABS/PS/HIPS/PA/PC/PU/EPS Extruder Capacity 180-1000kg/H Delivery Period 35-45work Days Motor Brand Siemens Electrical Apparatus Element Schneider/Siemens Blade Material SKD-11/DC53 Warranty Period 5 Years Screw Material Bimetallic Spare Parts Supply for Free Forever Frequency Converter ABB Transport Package Seaworthy Packing for PE Film Pelletizing Machine Specification Top Feed(PE Film Compactor Granulating Machine) Trademark KWELL Origin China HS Code 84772010 Production Capacity 10sets/MonthProduct Description

PE Film Agglomerator Granulating Machine1. Introduction and Application

This machine can be used to recycle clean HDPE/LDPE/LLDPE/PP/BOPP/ABS/PS/HIPS/PA/PC/PU/EPS/EVA, etc.

2. Features

1. Screw charger uploading material by timer

2. Feeder and extruder are controlled by inverter

3. Various L/D for Various material

4. Natural degassing, vacuum degassing adopting for moisture

5. Water ring die face cutting or strand noodle cutting

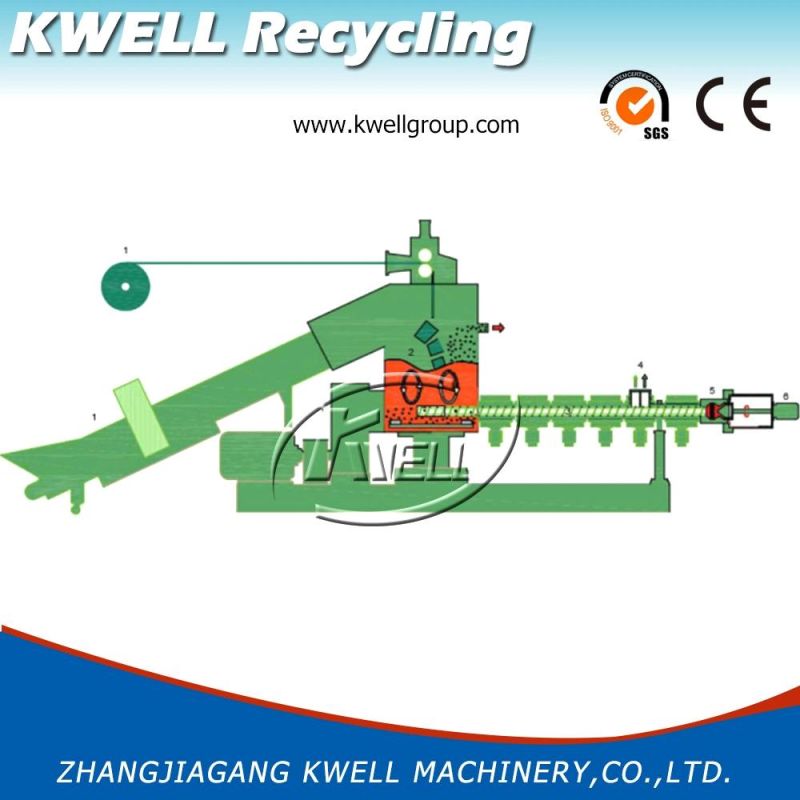

6. How it works:

1 Feeder(belt feeder/reel feeder)

Feeding is automatic according to customer requirements.

2 Compactor

The material is cut in the compactor, mixed, heated, dried, densified and buffered.

3 Extruder

Melting the plastic and extruding

4 Degassing zone

the air and water is volatilized here.

5 and 6 Pelletizer

The material is extruded to the die.

3. Parameter

| Extruder Model | Compactor Power(kw) | Extruder Power(kw) | Capacity(kg/h) |

| SJ85 | 37 | 55 | 180-250 |

| SJ100 | 55 | 90 | 250-300 |

| SJ120 | 75 | 110 | 300-400 |

| SJ130 | 90 | 132 | 400-500 |

| SJ150 | 90 | 160 | 500-600 |

| SJ160 | 110 | 185 | 600-700 |

| SJ180 | 160 | 250 | 800-1000 |

4. After-sales Service

1. Provide with installation, commissioning and training

2. Register and record customer information

3. Offer spare parts

4. Provide with necessary technical support for new application

5. Visit customer regularly and correct information

5. PE Film Agglomerator Granulator

6. Granule

7. Package and Loading

8. Certificates

9. Favorable Policy

1. Warranty period for 5 years

2. Supply free spare parts forever

10. Company Profile

Zhangjiagang Kwell Machinery Co., Ltd.

Kwell machinery is a leading manufacturer of plastic recycling and extrusion machinery in China. Our company is located in Zhangjiagang City, Eastern Coast of China, with a history of more than 15 years and has 500 employees.

With the deep understanding of the plastic recycling & extrusion technology and owning excellent metal processing ability, we are trying our best to be out of the common in the product quality. We have been supplying a wide range of plastic machinery and after-sales services to our customers from more than 150 countries and regions.

Our company has taken the lead to obtain CE certificate, SGS certificate, IS09001: 2008 quality management system certification, persevere in the full implementation of "zero defect" quality control, strengthens the control of purchasing and supply, production technology, quality inspection, production marketing, capital arrangements, after-sales service and so on.

Continuous accumulated R&D and manufacturing experience, grasping of the latest recycling & extrusion technology and advanced management system, which make us to be your reliable and faithful business partner.

Company Mission:

1. Dedicate in plastic recycling and extrusion technology

2. Concentrate on customer's requirements

3. Supply best quality of product at competitive price, as well as considerate & prompt after sell service

Company Motto:

Focus On Details, Achieve In Success

Address: Yongli Industrial Zone, Leyu Town, Zhangjiagang, Suzhou, Jiangsu, China

Address: Yongli Industrial Zone, Leyu Town, Zhangjiagang, Suzhou, Jiangsu, ChinaOffice Phone: 0086-512-58565868

Fax: 0086-512-58565868

Website: http://kwellgroup.en.made-in-china.com/

Any suggestion and questions, just feel free to contact us and we are pleased to recommend suitable configuration for you.