Ypj800 Stainless Steel Water Cooled Cooling System for Electrostatic Powder Coating

Yantai Jatchen Powder Coating Processing Equipment Co., Ltd.- Type:Sheet Extruder, Roller Crusher

- Plastic Processed:Polystyrene

- Product Type:Powder Coating Equipment

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

Base Info

- Model NO.:YPJ800

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Object:Plastic

- Drive:Electric

- Crushing Degree:Intermediate Crusher

- Crushing Style:Extruding and Milling

- Principle:Roller Culling

- Cutter Material:High-Speed Steel

- Finished Surface:Thread Process

- State:Brand New

- Transport Package:Wooden Frame

- Specification:YPJ800A,800AG

- Trademark:Jatchen

- Origin:China

- HS Code:8474809090

- Production Capacity:120 Pieces Per Year

Description

Basic Info.

Model NO. YPJ800 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Object Plastic Drive Electric Crushing Degree Intermediate Crusher Crushing Style Extruding and Milling Principle Roller Culling Cutter Material High-Speed Steel Finished Surface Thread Process State Brand New Transport Package Wooden Frame Specification YPJ800A/800AG Trademark Jatchen Origin China HS Code 8474809090 Production Capacity 120 Pieces Per YearProduct Description

Cooling Band of series YPJCooling band is composed of cooling-sheeting rolls, knotty stainless steel band conveyor and crusher. The kneaded thermal materials output from extruder is sheeted at thickness of 1-2mm. The rolls are cooled by water and air. The sheeted tape material is transported to crusher and cooled by fans continually. The crushed chip material falls down to the hopper.

Features:

1.Double layer chrome plate cooling roll, Better cooling effect, higher working efficiency

2.Stainless steel Chip's thickness

3.Conveying speed can be adjustable

4.Tape material cooled by clean cooling air

5.Roller and crusher equipped with overload protection device

6.Cooling roll has automatic reverse motion control

7.Easy to clean and maintenance

8.Safe to operate

Technical Parameters:

| Model | Roll Diameter (mm) | Bandwidth (mm) | Band length (mm) | Power (KW) | Throughput (kg/h) | Cooling mode | Dimension (m x m x m) |

| YPJ600 | 190 | 600 | 3500 | 1.1 | 120 | cooling water/wind | 4.0x0.8x1.2 |

| YPJ800A/800AG | 245/325 | 800 | 4500 | 1.5 | 300 | cooling water/wind | 5.5x1.1x0.9 |

| YPJ1000A/1000AG | 245/325 | 1000 | 5000 | 2.2 | 500 | cooling water/wind | 5.8x1.1x1.0 |

Company Introduction

Yantai Jatchen Powder Coating Processing Equipment Co., Ltd, established in 2011, which specialized in researching and manufacturing of powder coating processing equipment with strong technical team and rich experience. We passed CE certification approval and ATEX explosion resistant test, etc. international standards, "Quality first, Credit first and customer first" is our eternal pursuit. We are committed to provide commissioning and installation support, formulation guidance and 24-hour after-sale service.

Our products have been successfully exported to many countries and regions. like America, Brazil, Canada, India, Turkey, etc. We sincerely welcome you to our company for business visit. we'll try our best to provide the best equipment and solutions to our customers.

Workshop- With highly advanced & precise machining center

- With well-trained & experienced workers

- With strict quality control system

- With EHS & 6S management system

Patent & Qualification:

Why choose us?

"Leading design" + "Excellent performance" + "Best service" = Jatchen's advantages

- Leading design: the richest experienced R&D team, more than 20 years only keeping eyes on powder coating industry.

- Excellent performance : the miracle particle distribution result, the biggest savings of materials and labor for your clients.

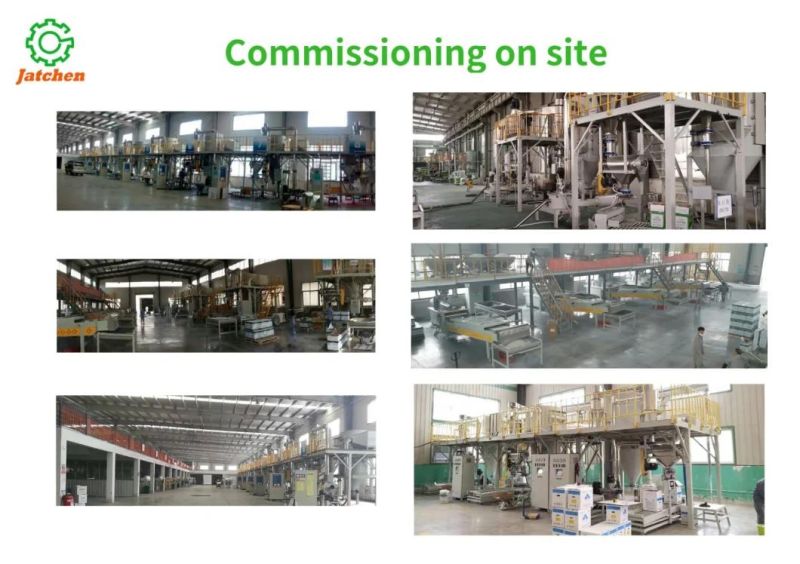

- Best service: we are committed to 24-hour service, including video technical support, online support, commissioning on site etc.

Successful Cases: