1000 Kg Per Hour Waste Plastic Pet Flakes Ready Made Recycling Plant Washing Line with Ce

Jiangsu Acemien Machinery Co., Ltd.- Material Processed:Plastic Bottle

- Plastic Type:PET

- Screw:Double-Screw

- Automation:Automation

- Computerized:Computerized

- Certification:CE

Base Info

- Output:300-3500 Kg,H

- Model NO.:PET-001

- Guarantee Period:12 Months

- Delivery Time:30-90 Workdays

- Transport Package:Wooden Case ,Plastic Film(or Customer′s)

- Specification:PET 300-3500

- Trademark:ACEMIEN

- Origin:China

- HS Code:84778000

- Production Capacity:350 Sets,Year

Description

Moisture: max 2%

Bulk density: 0.3g/cm3

Particle size: 12-16mm

Total impurity: 320ppm

PVC content: 100ppm PP/PE content: 200ppm Metal content: 20ppm

Superiority of PET Bottle Recycling Line :

1. High automation level, try best to reduce your cost on labor (especially for three shifts) and ensure high processing capacity: 500-3500kg/hr

2. Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop.

3. All parts contacting with plastic material and water are made of high-quality 304 stainless steel; Ensure no second pollution to flakes.

4. Ideal impurity removal effect.

5.Motor:Siemens, WEW

Gear reducer:SEW, FALK

Bearing:SKF, FAG, NSK

PLC:Siemens, Schneider, Beckhoff

Inverter:ABB, Schneider, Siemens

Pressure sensor:Dynisco, Gefran

Low voltage component:Siemens, Schneider, Omron, LS

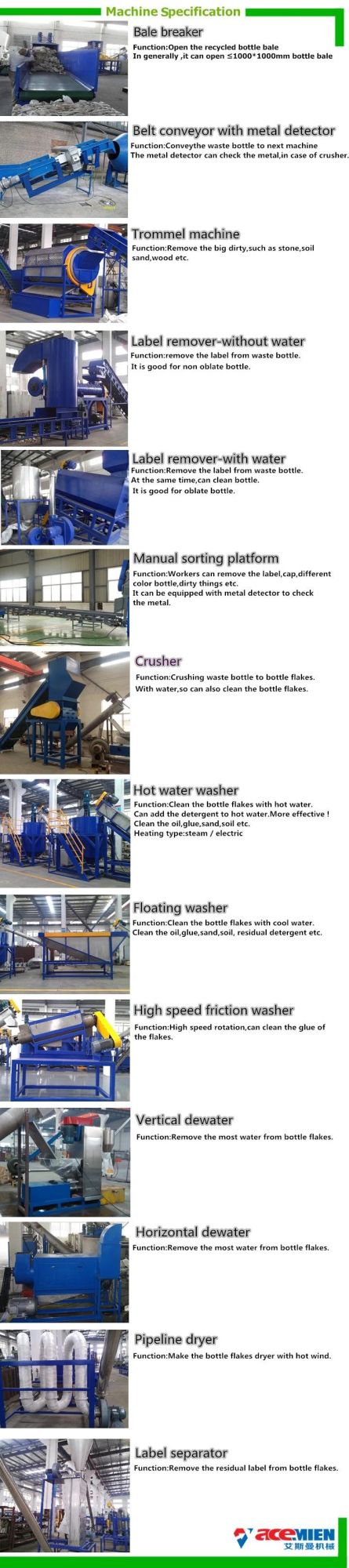

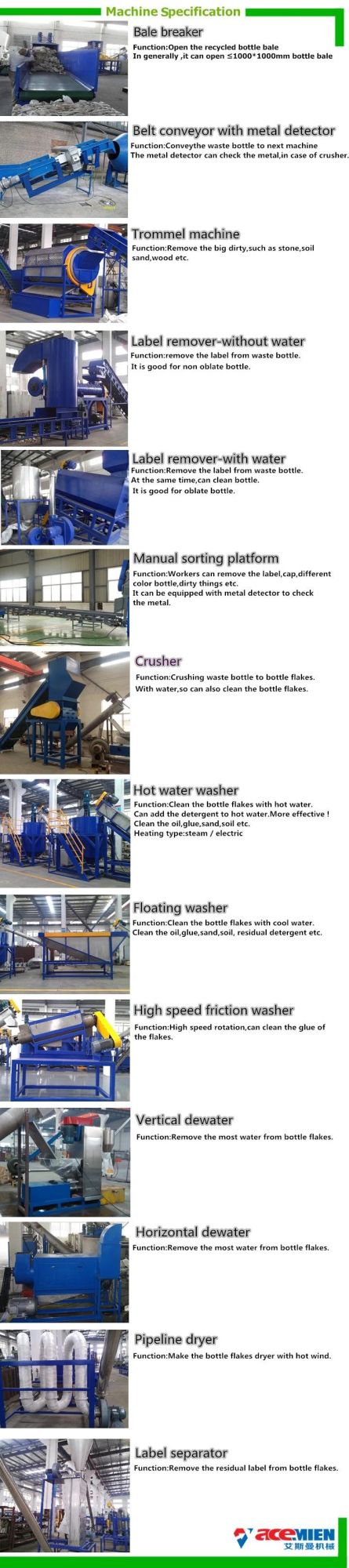

Production Line List for reference: Total20 sets

General information(Take capacity 1000kg/h as example):After shipping,two engineers will go to customer's company to install and test machine,and teach customer's workers the operative skills. - pre-sales services:

we will take customers to visit our factory and check the machines quality from airport/bus station/train stations.

- we will re-designed the machines according to customer's different raw material formulations: driving motors power, electric power model, control method etc. - after sales services:

we will offer electric diagram, installation diagram, usage manual.

- we will offer the customers online introduction to solve the machines problems/send engineers for customers machines installation, running test, workers training, machines repairmen services etc.

- we will offer customers spare parts at cost prices all life long of the machines .

Company info

Bulk density: 0.3g/cm3

Particle size: 12-16mm

Total impurity: 320ppm

PVC content: 100ppm PP/PE content: 200ppm Metal content: 20ppm

Superiority of PET Bottle Recycling Line :

1. High automation level, try best to reduce your cost on labor (especially for three shifts) and ensure high processing capacity: 500-3500kg/hr

2. Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop.

3. All parts contacting with plastic material and water are made of high-quality 304 stainless steel; Ensure no second pollution to flakes.

4. Ideal impurity removal effect.

5.Motor:Siemens, WEW

Gear reducer:SEW, FALK

Bearing:SKF, FAG, NSK

PLC:Siemens, Schneider, Beckhoff

Inverter:ABB, Schneider, Siemens

Pressure sensor:Dynisco, Gefran

Low voltage component:Siemens, Schneider, Omron, LS

Production Line List for reference: Total

General information(Take capacity 1000kg/h as example):

we will take customers to visit our factory and check the machines quality from airport/bus station/train stations.

- we will re-designed the machines according to customer's different raw material formulations: driving motors power, electric power model, control method etc.

we will offer electric diagram, installation diagram, usage manual.

- we will offer the customers online introduction to solve the machines problems/send engineers for customers machines installation, running test, workers training, machines repairmen services etc.

- we will offer customers spare parts at cost prices all life long of the machines .

Company info

| Company | Jiangsu Acemien Machinery Co.,ltd |

| Address | No 2,Changhong Road,Modern Agriculture Demonstration Park,Zhangjiagang City, China |

| Area | ≥ 10000 square meter |

| Manpower | ≥ 80 persons |

| Certification | CE SGS |

| Professional manufacture | 1) Plastic waste film/ bottle recycling and washing machine 2) Plastic Roof Tile Machine 3) PVC Roof Tile Machine 4) PVC Corrugated Tile Production Line 5) PE,PVC,PP-R,PERT solid pipe extrusion line 6) WPC,PVC profile,door panel,foamed panel,ceiling panel extrusion line 7) Plastic granulating machine 8) Auxiliary machine,such as mixer,crusher,pulverizer etc. |