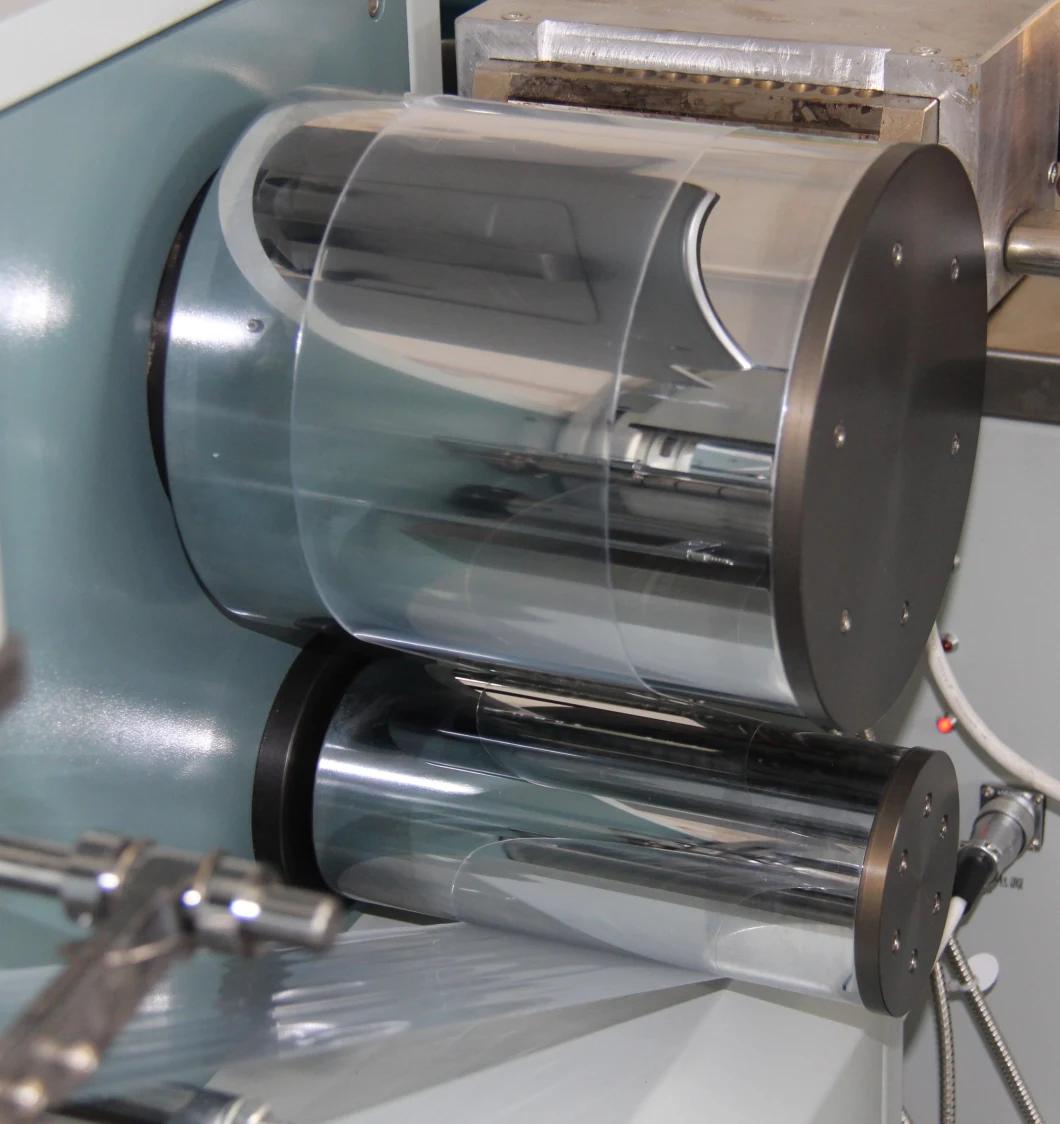

The Mould Assembly of The Casting Film Machine for Rubber and Plastic Processing Machinery

Harbin Hapro Electric Technology Co., Ltd.- After-sales Service:a Lifetime

- Warranty:1 Year

- Standard:DIN, ASTM, GOST, GB

- Technics:Casting

- Feature:Recycle

- Material:Stainless Steel

Base Info

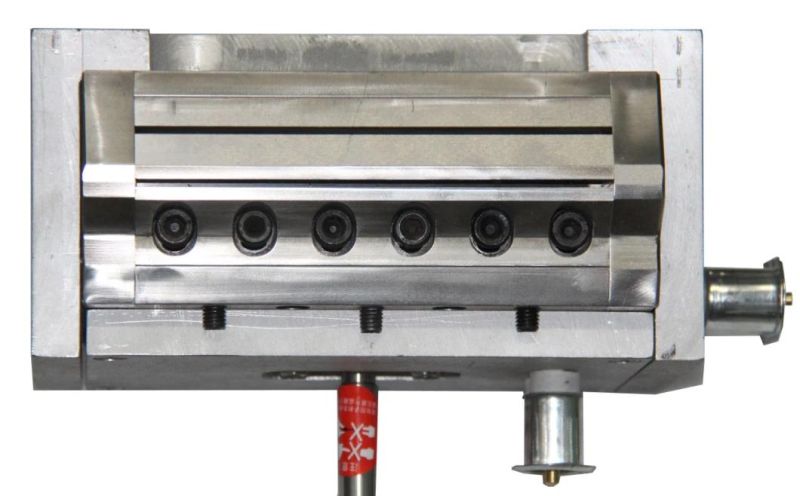

- Heating:Electric Heating

- Pressure Sensor:1

- Max.Pressure:100bar

- Mould Width:150mm

- Mould Thickness:0-2.5 mm Adjustable

- Mould Heating Power:2.1kw

- Transport Package:Plywood

- Trademark:Hapro

- Origin:China

- HS Code:9024900000

- Production Capacity:100,Year

Description

Basic Info.

Heating Electric Heating Pressure Sensor 1 Max.Pressure 100bar Mould Width 150mm Mould Thickness 0-2.5 mm Adjustable Mould Heating Power 2.1kw Transport Package Plywood Trademark Hapro Origin China HS Code 9024900000 Production Capacity 100/YearProduct Description

Mold (Mu Ju), industrial production for injection molding, blow molding, extrusion, die casting or forging, forming, smelting, stamping and other methods to get the required products of all kinds of molds and tools. In short, the mold is used to make the tools of molding items, this tool is composed of a variety of parts, different molds by different partsIt is mainly through the physical state of the material to achieve the shape of the processing of goods known as the "mother of industry" title.

Tools that make billets into parts of specific shape and size under the action of external force are widely used in punching die forging, cold heading extrusion, powder metallurgy parts, pressure casting, and engineering plastics, rubber, ceramics and other products, pressure molding or injection molding

Mold with a specific or inner cavity shape, the outline of the application has the edge contour shape can be made according to the outline shape occur separation (blanking) application within the cavity shape can make the blank to get the corresponding three-dimensional shape Mould generally includes moving die and die (or punch and die) two parts, can be divided into two separated can close out parts, folded shape billet injection mold cavity

Mold is a precision tool, the shape is complex, bear billet bulging force, the structural strength stiffness, surface hardness, surface roughness and processing precision have higher requirements, the development level of mold production is one of the important marks of the level of machinery manufacturing

The plastic mould is a coordinated change of the composite mould for emboplastic injection blow and low foaming molding, which can be processed in different shapes of different shapes.

The casting mould is suitable for the casting film forming of polymer materials such as PE, PP, PS, ABS, PVC, PET, PC and so on