Plastic PP PE PPR HDPE Pipe Making Machine Manufacturer

Qingdao Tongsan Plastic Machinery Co., Ltd.- After-sales Service:Engineer Oversea Service

- Warranty:12 Months

- Type:Pipe Extruder

- Plastic Processed:PP,PE,PPR,HDPE Pipe

- Product Type:PP,PE,PPR,HDPE Pipe

- Feeding Mode:One Feed

Base Info

- Model NO.:SJ-65,33

- Assembly Structure:Integral Type Extruder

- Screw:Single-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Production Speed:8-20m,Min

- Capacity:80-140kg,H

- Main Motor:Siemens

- Motor Power:30kw

- Inventer:ABB

- Temperature Controller:Omron

- PLC Controller:Optional

- Qarranty Period:One Year

- Delivery Time:30-60 Days

- Transport Package:Sea Worth Package

- Specification:SJ65,33

- Trademark:TONGSAN

- Origin:China

- HS Code:84772090

- Production Capacity:100 Sets One Year

Description

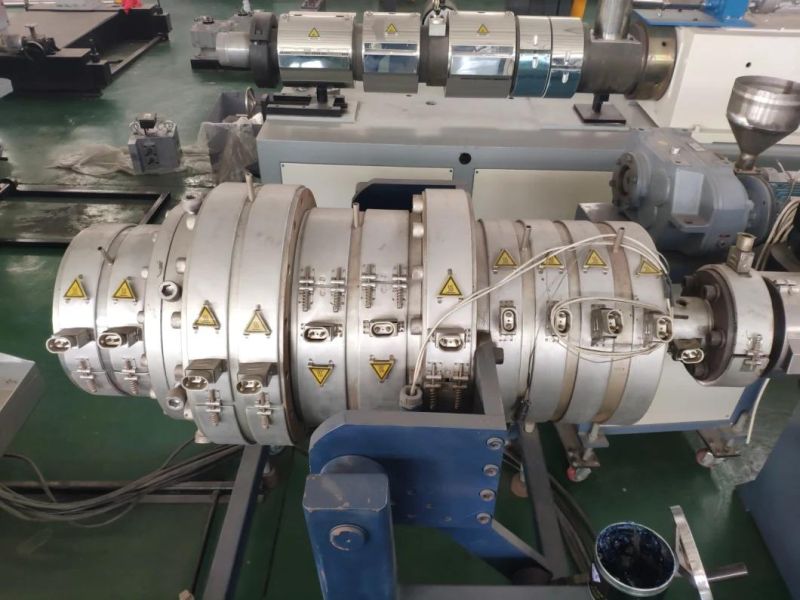

(1)High quality single screw extruder

(1)High quality single screw extruder According to different diameetr of pipe, equipped with different model screw extruder.

with auto feeding machine and dryer hopper.

Simens brand motor

ABB frequency inverter.

Omron temperature controller.

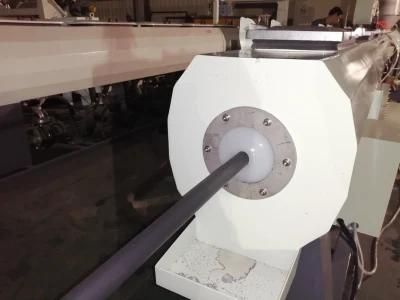

(2) Professional designed die head and mould

The diameter of the pipe can be 16-630mm.

Made of Mould steel.

(3)Vacuum calibrating tank and water cooling tank

(3)Vacuum calibrating tank and water cooling tankAccording to the different diameter of pipe. euqipped different quantity of tanks.

6m length equipped with vacuum pump and water pump.

The part which connect with water is made of stainless steel. (4)Hual off machine

Smaller diameter pipe and big diameter pipe use different haul off machine.

(5)Double station winding machines or Cutting and staker

(5)Double station winding machines or Cutting and staker

About HDPE Pipe Application

HDPE pipes must bear a certain pressure. PE resins with high molecular weight and good mechanical properties are usually used, such as HDPE resins. LDPE resin has low tensile strength, differential pressure resistance, poor rigidity, poor dimensional stability during molding and difficult connection, and is not suitable as a material for water supply pressure pipes. However, due to its high hygienic index, LDPE especially LLDPE resin has become a common material for the production of drinking water pipes. LDPE and LLDPE resins have low melt viscosity, good fluidity and easy processing, so their melt index can be selected in a wide range, usually with MI between 0.3-3g/10min.

HDPE pipe is a good pipeline. It should not only have good economy, but also have a series of advantages such as stable and reliable interface, impact resistance, crack resistance, aging resistance, corrosion resistance, etc. Compared with traditional pipes, HDPE piping system has The following series of advantages:

1,Reliable connection: The polyethylene pipe system is connected by electric heat melting, and the strength of the joint is higher than the strength of the pipe body.

2,Good low-temperature impact resistance: The low-temperature embrittlement temperature of polyethylene is extremely low, and it can be used safely in the temperature range of -60-60ºC. During construction in winter, because the material has good impact resistance, the pipe will not be brittle.

3,Good stress crack resistance: HDPE has low notch sensitivity, high shear strength and excellent scratch resistance, and its environmental stress crack resistance is also very outstanding.

4,Good chemical resistance: HDPE pipelines can withstand the corrosion of a variety of chemical media, and the chemical substances in the soil will not cause any degradation to the pipeline. Polyethylene is an electrical insulator, so it will not rot, rust or electrochemical corrosion; in addition, it will not promote the growth of algae, bacteria or fungi.

5,Aging resistance and long service life: The polyethylene pipe containing 2-2.5% evenly distributed carbon black can be stored or used outdoors for 50 years without being damaged by ultraviolet radiation.

6,Good wear resistance: The comparison test of the wear resistance of HDPE pipes and steel pipes shows that the wear resistance of HDPE pipes is 4 times that of steel pipes. In the field of mud transportation, HDPE pipes have better wear resistance than steel pipes, which means that HDPE pipes have a longer service life and better economy.

7,Good flexibility: The flexibility of HDPE pipeline makes it easy to bend. In engineering, obstacles can be bypassed by changing the direction of the pipeline. In many cases, the flexibility of the pipeline can reduce the amount of pipe fittings and reduce installation costs.

8,Small water flow resistance: HDPE pipe has a smooth inner surface, and its Manning coefficient is 0.009. The smooth performance and non-adhesive characteristics ensure that HDPE pipes have a higher conveying capacity than traditional pipes, and also reduce the pressure loss of the pipeline and the energy consumption of water transmission.

9,Convenient handling: HDPE pipes are lighter than concrete pipes, galvanized pipes and steel pipes. It is easy to handle and install. Lower manpower and equipment requirements mean that the installation cost of the project is greatly reduced.

10,Various new construction methods: HDPE pipeline has a variety of construction technologies. In addition to traditional excavation methods, it can also use a variety of new non-excavation technologies such as pipe jacking, directional drilling, liner, It is a good choice for some places where excavation is not allowed.

About our company