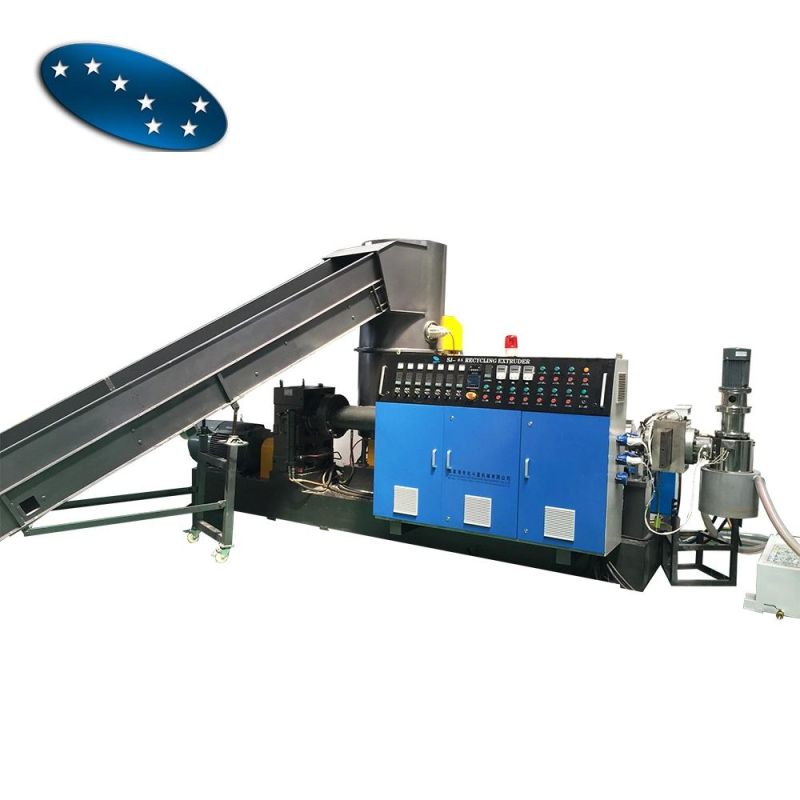

PE PP HDPE Granules Making Machine

Zhangjiagang Sevenstars Machinery Co., Ltd.- Raw Material:PE

- Screw:Multi-Screw

- Inverter:Inverter

- Electromagnetic Heater:Without Electromagnetic Heater

- Automation:Automatic

- Computerized:Computerized

Base Info

- Model NO.:BDX

- Customized:Customized

- Certification:CE, ISO9001:2008, QS, UL, GMP

- Condition:New

- Motor:Siemens

- Output:100kg-1500kg,Hr

- Cooling:Water Cooling

- Warranty:12 Months

- Cutting Type:Noddle Pelleting (Water Ring Pelleter)

- Screw Diametre:65-180mm (Customized:)

- Transport Package:Seaworthy Packing

- Specification:CE ISO9001: 2008 SGS

- Trademark:BDX

- Origin:Jiangsu Zhangjiagang

- HS Code:84772010

- Production Capacity:17sets,Year

Description

Basic Info.

Model NO. BDX Customized Customized Certification CE, ISO9001:2008, QS, UL, GMP Condition New Motor Siemens Output 100kg-1500kg/Hr Cooling Water Cooling Warranty 12 Months Cutting Type Noddle Pelleting (Water Ring Pelleter) Screw Diametre 65-180mm (Customized:) Transport Package Seaworthy Packing Specification CE ISO9001: 2008 SGS Trademark BDX Origin Jiangsu Zhangjiagang HS Code 84772010 Production Capacity 17sets/YearProduct Description

PE PP hdpe granules making machine

The whole production line

The plastic raw materials which have been enhancing, filling and blending should be used for injection or extrusion molding after granulation. For how to choose the appropriate granulation methods, our professional team will provide you professional technical support.

Characteristics:

1. The gear box

1) Rotating speed: MAX 600~1500RPM

2) Combining host transmission box speed reduction and torque distribution part together, using three axis style design, with compact structure. Speed reduction, torque distribution and two output Shaft radia bearing all use NSK bearings.

3) Gear is 6 grade which is a high precision. High speed overloading hard-tooth surface. The materials are 20CrNi2MoA or 20CrMnMo, HRC 60/62.

2. The feeding system

Various forms of feeding structure and system single screw extruder, twin screw, hollow spring type, Mesh and mesh, can cover the various material status

3. Screw and barrels

Screw Kneading block built on modular principle allows various L/D ratio of screw easily be changed to Suit different material. Screw component made of high speed & wear-resisting steel.

The screw elements are designed accurately and made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heater treatment.

BRP twin screw pelletizing machine technical parameter:

| Model | Screw Diameter D (mm) | screw L/D | screw speed N (r/min) | Main motor power P(KW) | Screw Torque T (N.m) | Torque Level T/N³ | Capacity Q(kg/h) |

| BRP20 | 21.7 | 28~40 | 600 | 3/4 | 30 | 4.8 | 3-15 |

| BRP35 | 35.5 | 28~56 | 500 | 11 / 15 | 115 | 4.2 | 20-70 |

| BRP50 | 50.5 | 28~56 | 500 | 45 / 55 / 75 | 425 | 5.1 | 80-150 |

| BRP52B | 51.4 | 28~56 | 400/500/600/800 | 45 / 55 / 75 | 425 | 5.1 | 120-280 |

| BRP65 | 62.4 | 28~56 | 500 / 600 | 55 / 75 / 90 | 675 | 4.8 | 150-300 |

| BRP65B | 62.4 | 28~56 | 400/500/600/800 | 90/110 | 675 | 4.8 | 200-500 |

| BRP75 | 71 | 28~56 | 500 / 600 | 90 /110 /132 | 1005 | 4.6 | 300-550 |

| BRP75B | 71 | 28~56 | 400/500/600/800 | 110 /132/180 | 1005 | 4.6 | 300-700 |

| BRP95 | 93 | 28~56 | 400 / 500 | 250 / 315 | 2815 | 5.9 | 600-1000 |