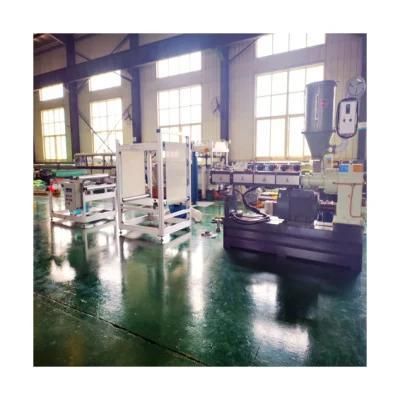

PP Melt Blown Facbric Making Machine for Making Face Mask

Qingdao Tongsan Plastic Machinery Co., Ltd.- Type:Sheet Extruder

- Plastic Processed:PP

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

Base Info

- Model NO.:SJ-65

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Melt Blown Capacity:350-450kg,Day

- Melt Blown Extruder Size:Sj65,30

- Main Motor:22kw Siemens Brand

- Inverter:ABB Brand

- Temperature Control:Omron

- Contractor:Siemens

- Melt Blown Machine Color:Customized

- Melt Blown Material:PP

- Melt Blown Method:Extrusion-Spraying-Forming

- Melt Blown Fabric Size:600mm

- Melt Blown Fabric Weight:25 Gram,Square Meter

- Melt Blown Fabric Quality:Pfe95+ and Bfe99+

- Certificate:Ce Certificate

- Melt Blown Cloth Use:Medical Mask, N95 Mask, Filter Material

- Melt Blown Mold:Spraying Mold

- Transport Package:Film Wrapping, Wooden Case, Strong Pallet

- Specification:600mm

- Trademark:Tongsan

- Origin:China

- HS Code:84772090

- Production Capacity:10 Sets,Month

Description

1, Material auto mixing and feeding machinethe mixer is fully made by stainless steel.the auto feeding is by vacuum suctionthe hopper with drying fuction

1, Material auto mixing and feeding machinethe mixer is fully made by stainless steel.the auto feeding is by vacuum suctionthe hopper with drying fuction

2, SJ65/30 Extruder machineSpecial design screw for PP melt blownAluminum high quality heaterspecial water cooling design for feeding zone

3, hydraulic screen changerautomatic screen changerno leaking material

4, melt metering pumpSpecial designed for PP melt blown fabric materialAccurate flow control

5, Die head and Spinneret platehigh quality mold materialhole of Spinneret: 0.25mmConnection type: down sprayingFabric width: 600mm

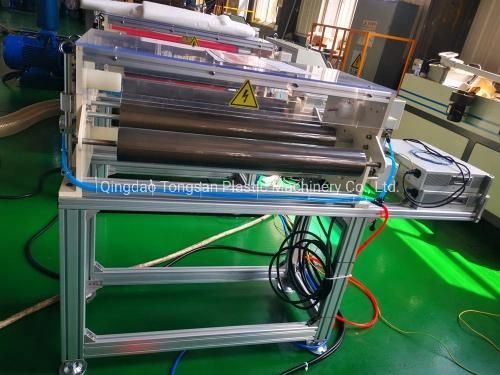

6, Fabric forming machine Forming type: Mesh belt formingWidth of belt: 1000mmMachine height adjustment: motor liftingMachine moving method: wheels moving

7, Roost blowerStrong power: 37 KWLow noise with noise insulation systemSafety operation with pressure adjustment

8, Air heating deviceFast heating system: 60kwTemperature control system: automaticBig air tank with heat insulation

9, electrostatic devicestrong electrostatic: 100KVDouble faces processingdouble times for each face

10,auto online split cutting machineOnline automatic splittingsplitting width: adjustablequantity of knives: 3-4 pcs11, winding machinemax winding width: 800mmmax winding diameter: 500mmwinding type: automatic windingeasy change winding rolls

12, Electric control systemABB inverter controlSiemens contractorOmron temperature controlSiemens PLC system is optional5.PP melt blown fabric applicationMelt-blown non-woven fabric is a kind of rapid development in the production of non-woven fabric. It is known as the one-step polymer production process with the shortest process abroad. Its products have many obvious advantages such as high filtration efficiency, low resistance, flexibility, and the network can bind and bond itself. Therefore, it is widely used in various countries, and its main uses are medium-efficiency and sub-efficiency filtration, including air filtration and acid destruction. Liquid filtration food hygiene filtration, industrial dust mask manufacturing, etc., in addition, can also be used as medical and hygiene products, industrial precision wipes, thermal insulation materials, oil-absorbing materials, battery separators, imitation leather base cloth and so on. In many ways, its performance is better than similar products of traditional textiles. With the continuous development of post-processing technology, the application fields of melt-blown non-woven fabrics will be more extensive.

12, Electric control systemABB inverter controlSiemens contractorOmron temperature controlSiemens PLC system is optional5.PP melt blown fabric applicationMelt-blown non-woven fabric is a kind of rapid development in the production of non-woven fabric. It is known as the one-step polymer production process with the shortest process abroad. Its products have many obvious advantages such as high filtration efficiency, low resistance, flexibility, and the network can bind and bond itself. Therefore, it is widely used in various countries, and its main uses are medium-efficiency and sub-efficiency filtration, including air filtration and acid destruction. Liquid filtration food hygiene filtration, industrial dust mask manufacturing, etc., in addition, can also be used as medical and hygiene products, industrial precision wipes, thermal insulation materials, oil-absorbing materials, battery separators, imitation leather base cloth and so on. In many ways, its performance is better than similar products of traditional textiles. With the continuous development of post-processing technology, the application fields of melt-blown non-woven fabrics will be more extensive.1. Application in the field of air purification Used in air purifiers, as a sub-efficient and efficient air filter element, and for coarse and medium-efficiency air filtration at large flow rates. It has the advantages of low resistance, high strength, excellent acid and alkali resistance, corrosion resistance, stable efficiency, long service life and low price. There is no fluff in the gas purified by the filter.2. Application in the field of medical and health The dust-proof mouth made of melt-blown cloth has small breathing resistance, no sulking, and the dust-proof efficiency is as high as 99%. It is widely used in hospitals, food processing, mines and other workplaces that require dust and anti-bacterial products after special treatment. The anti-inflammatory and analgesic film made has good breathability, no toxic and side effects, and is easy to use. SMS products combined with spunbond cloth are widely used in the production of sanitary products such as surgical clothes and hats.

3. Liquid filter material and battery separator Polypropylene meltblown cloth is used to filter acidic and alkaline liquids, oil, oil, etc. It has very good performance, has been regarded as a good separator material by the battery industry at home and abroad, and has been widely used, not only reduces battery costs, The process is simplified, and the weight and volume of the battery are greatly reduced.4. Oil-absorbing materials and industrial wipes Various oil-absorbing materials made of polypropylene melt-blown cloth can absorb oil up to 14-15 times its own weight. It is widely used in environmental protection projects and oil-water separation projects. In addition, it can be used as a clean material for oil and dust in industrial production. These applications have fully utilized the characteristics of polypropylene itself and the adsorption of ultrafine fibers produced by meltblown.5. Warm materials The average diameter of melt-blown ultrafine fibers is between 0.5 and 5m, the specific surface area is large, a large number of fine pores are formed in the cloth, and the porosity is high. A large amount of air is stored in this structure, which can effectively prevent heat loss, and has excellent thermal insulation, and is widely used in the production of clothing and various insulation materials. Such as leather jackets, ski shirts, cold clothes, cotton village cloth, etc., it has the advantages of light weight, warmth, no moisture absorption, good breathability, no moldy rotten.