Plastic Recycling Granulator Machine Used Plastic Recycling Machine Plastic Shredder

Zhengzhou Harvest Machinery Co., Ltd.- Material Processed:Various Plastic Material

- Automation:Automation

- Computerized:Computerized

- Certification:CE, SGS

- Name:Plastic Recycling Granulator Machine Used Plastic

- Shredder Type:Single Shaft Shredder

Base Info

- Shredder Blades:High Quality Material, Precise Processing Way

- Structure:Tangential Feed

- Knife Roller:Solid Knife Roller

- Roller Rotor:as Designed Based The Capacity

- Motor:Siemens

- Serivce:Technical Support

- Price:Competitive Factory Price

- Quality Control:100% Testing Machine

- Capacity:as Your Requrest

- Production Period:1 Month

- Technology:Mature

- Input Material:Various Waste Plastic

- Output Size:Plastic Granule

- Transport Package:Contanier

- Specification:as designed

- Trademark:HVST

- Origin:Zhengzhou, China

- HS Code:84778000

- Production Capacity:100set,Month

Description

Basic Info.

Shredder Blades High Quality Material, Precise Processing Way Structure Tangential Feed Knife Roller Solid Knife Roller Roller Rotor as Designed Based The Capacity Motor Siemens Serivce Technical Support Price Competitive Factory Price Quality Control 100% Testing Machine Capacity as Your Requrest Production Period 1 Month Technology Mature Input Material Various Waste Plastic Output Size Plastic Granule Transport Package Contanier Specification as designed Trademark HVST Origin Zhengzhou, China HS Code 84778000 Production Capacity 100set/MonthProduct Description

plastic recycling granulator machine used plastic recycling machine plastic shredderIntrodustion of single shaft shredder:

Single Shaft Shredders is designed to process waste plastic materials, these shredders are ideal for especially hard and voluminous products. The large shredding chamber and loading hopper capacity, combined with the PLC controlled horizontal RAM pusher ensures optimum feeding of material to the rotor therefore achieving the most efficient performance. Throughputs typically range between1, 500kg/hr and over12, 000kg/hr,etc

Specification for your reference:

| Model series | BH1500 | BH2000 |

| Feed opening (LXW)(mm) | 1500X1675 | 2000X1675 |

| Ram(mm) | 760 | 760 |

| Rotor diameter(mm) | 480 | 480 |

| Speed(r/min) | 80 | 80 |

| Screen (mm) | 40-100 | 40-100 |

| Rotor knives (pcs) | 84 | 95 |

| Counter knives (pcs) | 6 | 8 |

| Motor power (kw) | 90 | 55+55 |

| Hydraulic power (kw) | 11 | 11 |

| Weight (kg) | Approx 10200 | Approx 13800 |

| Dimension (LXWXH)(mm) | 3630X2870X2630 | 3630X4260X2630 |

Picture of single shaft shredder for your reference:

Material can shred:

Plastics Mouldings, Purgings/Lump, Profiles, Films etc.

Timber/Wood Pallets, Joiners Waste, Green Waste etc.

Paper & Cardboard Confidential Documents, Production Waste, Packaging Materials etc.

Copper Cable Household, Telecoms and Industrial Cables including S. W. A

Aluminum Used Beverage Cans (UBC's), Swarf, Cables etc.

Textiles Carpet (Rolls & Tiles), Garments etc.

Security Destruction Counterfeit Items, Faulty Goods, Out of Date Stock etc.

Foam Production Waste etc.

Mixed Household & Commercial Waste RDF/SRF Production

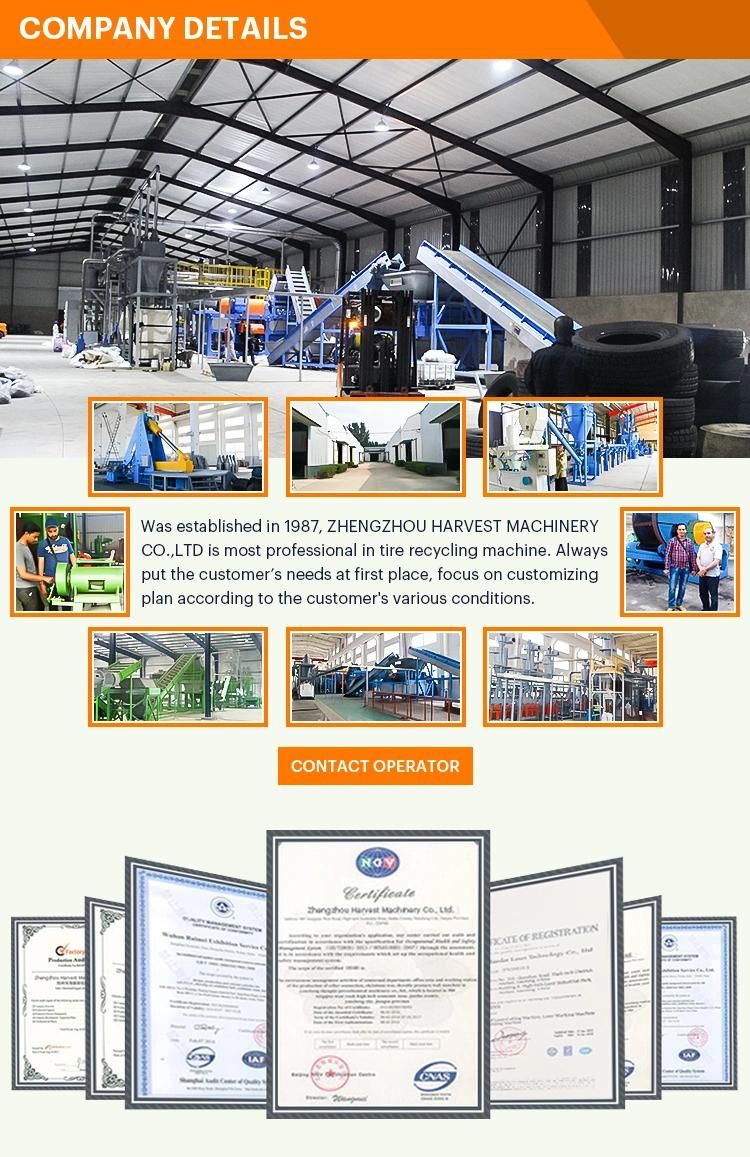

Company infomation:

We has been focuse odn designing and manufacturing equipment for the recycling industry more than 20 years, we mainly focued on providing our customer cost-effective waste recycling system applied in all kinds of waste recycling like tire/plastic/wood/metal/car/pcb board recycling,etc.

As a leader in providing cost effective turnkey tire recycling systems. Our main focus is to provide custom designed tire recycling systems that deliver optimum production for a variety of applications such as TDF (Tire Derived Fuel), rubber mulch, and rubber granule(crumb), rubber powder. We have manufactured and installed recycling systems in countries all over the world.

Service:

Before-sales service:

1. Technical proposal

2. Answer questions within 8 hours

3. Tested machine

After-sales service:

1. Install and debug machine, train workers

2. Free spare parts within gurantee period

3. Long time technical support when production process