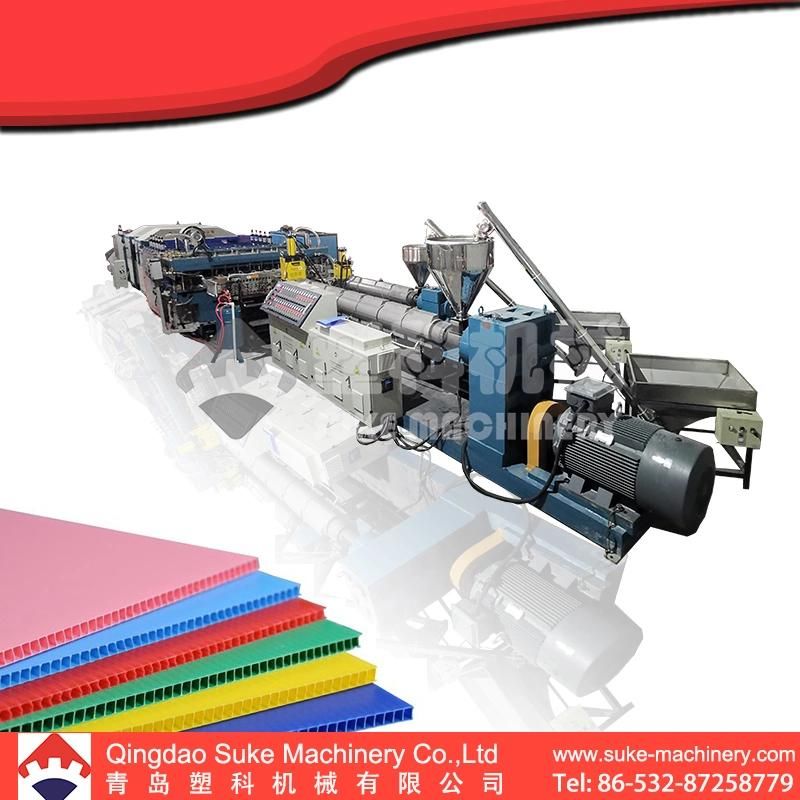

PC/PP Hollow Grid Sheet Extrusion Making Machine

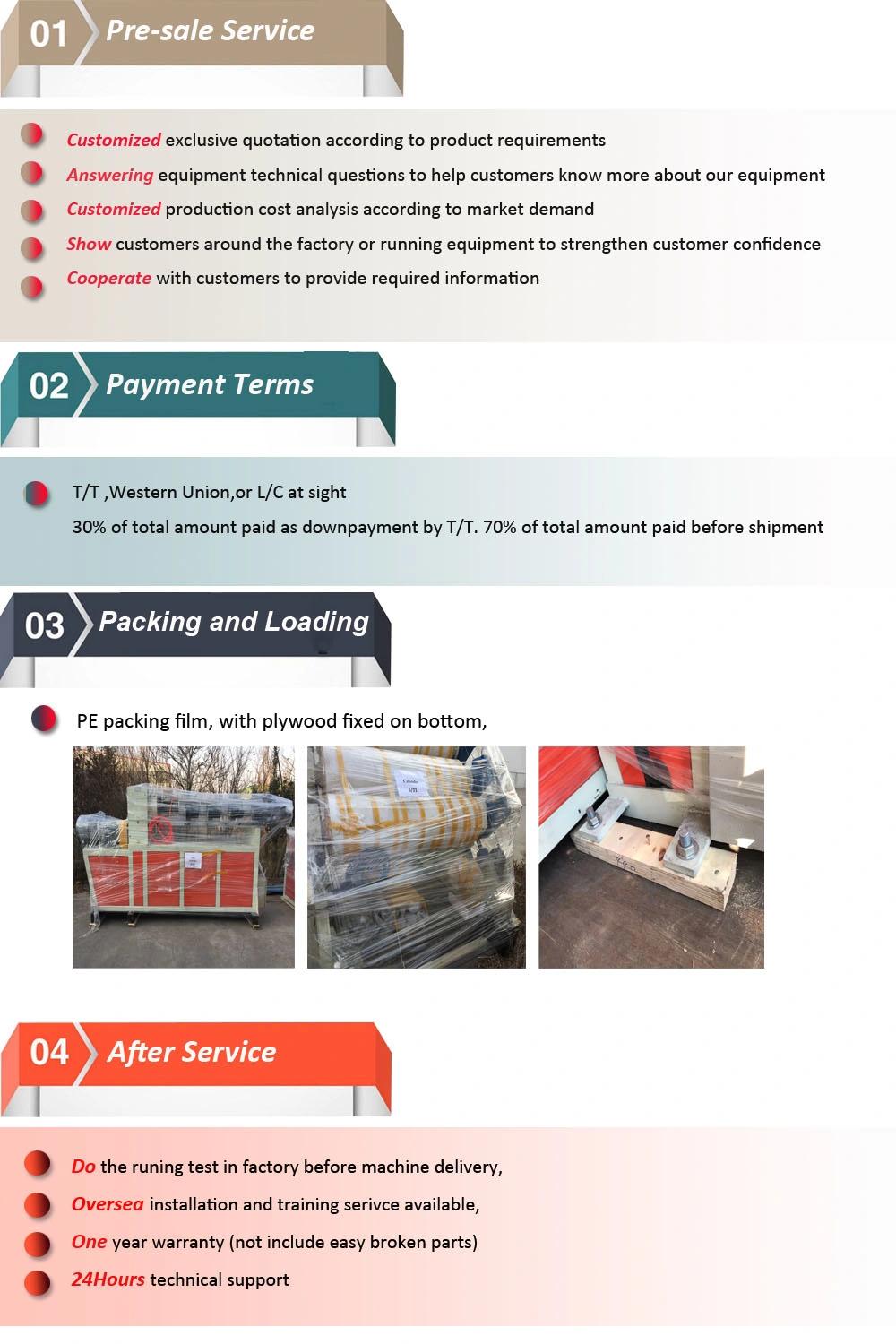

Qingdao Suke Machinery Co., Ltd.- Warranty:12monthes

- Product Type:PC Board

- Board Layers:Single Plate

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

Base Info

- Model NO.:SJ90,33

- Certification:CE, ISO9001:2008

- Customized:Customized

- Condition:New

- Extruder Model:Sj90,35

- Mould for Sheet/Board:T Type

- Button:Schneider

- Inverter:ABB

- Intelligent Temperature Controller:Omron

- Control System:PLC Control System

- After Sale Service:Life Long with Professional After Sale Team

- Machine Color:as Requst

- Connector:Schneider

- Transport Package:According to Your Requirement

- Specification:ISO9000 CE

- Trademark:SUKE

- Origin:Qingdao, China

- HS Code:84775900

- Production Capacity:40sets,Year

Description

Basic Info.

Model NO. SJ90/33 Certification CE, ISO9001:2008 Customized Customized Condition New Extruder Model Sj90/35 Mould for Sheet/Board T Type Button Schneider Inverter ABB Intelligent Temperature Controller Omron Control System PLC Control System After Sale Service Life Long with Professional After Sale Team Machine Color as Requst Connector Schneider Transport Package According to Your Requirement Specification ISO9000 CE Trademark SUKE Origin Qingdao, China HS Code 84775900 Production Capacity 40sets/YearProduct Description

PC Green House Plate Extrusion Line

MACHINE INTRODUCTION;

This line is also called hollow sheet extrusion line, is used to produce PC/PP hollow grid sheet/greenhouse plate by single screw extruder.

Sheet width: 800-2000mm

Sheet thickness: 2-20, single layer, or multilayer.

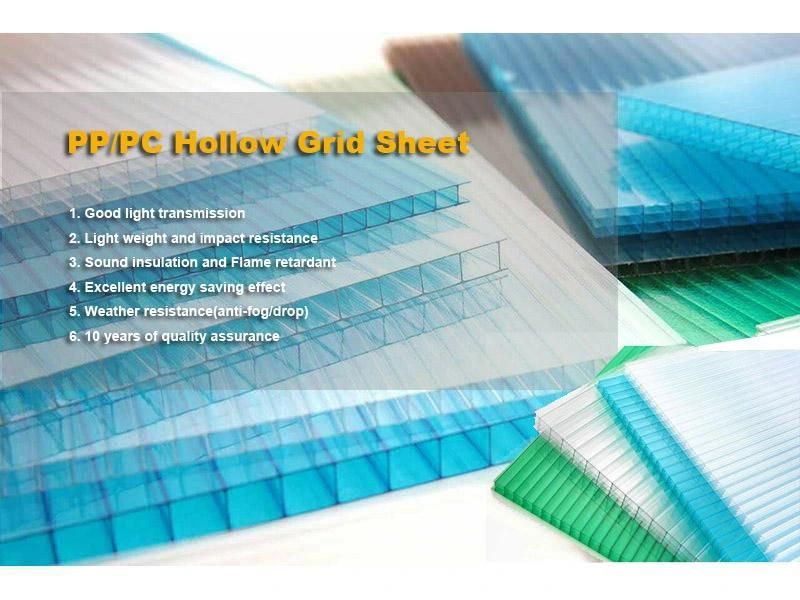

PP/PC hollow sheet is one of building materials with the characterists of hight weight(hollow structure), non-toxicity, pollution-free, water proof, shock-proof, anti-aging, anti-corrosion and rich colors.

PRODUCTION PROCESS FLOW:

Extruder---Mould--- Calibration plateform---Hual-off machine---cutting machine----collection plateform.

EQUIPMENT LIST:

.SJ90/33 Sigle Screw Extruder

2.Hydraulic screen exchanger, Gear pump

3. T-die

4. Air knife

5. calibration unit

6. the first haul-off unit

7. Side trimming machine

8. anneal oven

9. cooling system by air

10. Second haul-off unit

11. transverse cutter

12. transmission unit

13. Auxiliary equipment

14.Electrical appliances

MACHINE TYPE:

| Model | Extruder | Rollers Size | Output (Kg/h) | Product Width | Product Thickness |

| SK1500 | φ 120/35 | φ 400× 1500 | ≥ 300 | ≤ 1300MM | 1.2-15MM |

| SK1800 | φ 120/35 | φ 400× 1800 | ≥ 400 | ≤ 1700MM | 1.5-15MM |

| SK2300 | φ 130/35 | φ 450× 2300 | ≥ 500 | ≤ 2100MM | 1.8-15MM |