HDPE/PP Double Wall Corrugated Pipe Extrusion Line/Production Line/Plastic Pipe Making ...

Qingdao Tongsan Plastic Machinery Co., Ltd.- Warranty:1year

- Product Type:PE Pipe

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

Base Info

- Model NO.:SJ-300

- Customized:Customized

- Condition:New

- After-sales Service:Professional Engineers Teach Operation

- Name:Dwc Pipe Extrusion Machine

- Product Color:Tongsan Color

- Brand:Qingdao Tongsan

- Suitable Material:HDPE,PE,PVC,PP

- Keywords:Dwc Pipe Making Machine

- Cooling Way:Water Cooling

- Heating Way:Electrical Heating

- Transport Package:Wood Block Fixed Steel Wire Reinforcement

- Specification:ID110-250mm

- Trademark:Qingdao TONGSAN

- Origin:Qingdao, China

- HS Code:84772090

- Production Capacity:24,Years

Description

1.Extruder for High Speed Double wall corrugated DWC pipe machine

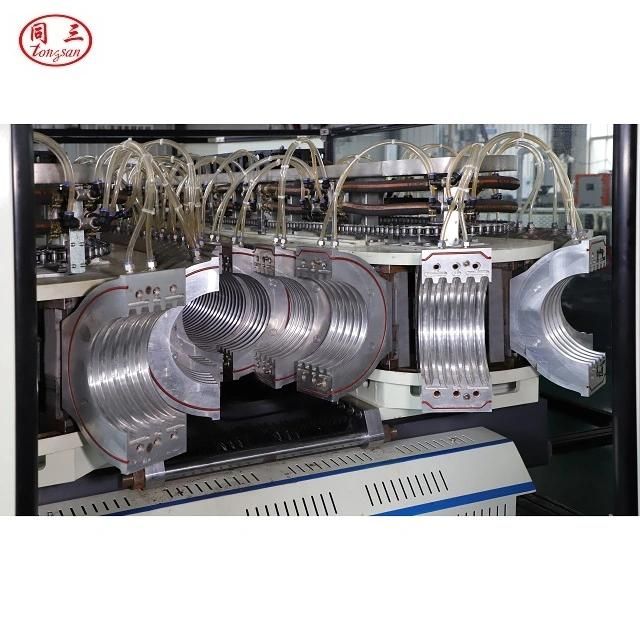

2. Forming Machine For High Speed DWC Double Wall Corrugated Pipe Machine

3. Mold for High Speed DWC double wall corrugated pipe machine

Based on the tube type requirements of the corrugated pipes, we have developed a vacuum forming system to ensure the production ofvarious shaped pipes.Our single wall corrugated pipe machines can produce fixed length inlet pipes and drains for washing

machines, and can produce shrinkable pipes with joints ,round and flat prestressed plastic corrugated pipes,etc.

We have professional mold design technicians,mold processing machines,machining center machines.We can design and process kinds of

corrugated pipe module block,corrugated pipe joint module blocks,letter engraving module blocks and other types corrugated pipe

block for any kinds of corrugated pipe according customer's requirements.All the module blocks are specialized grinding apparatus

steel,which is of high hardness and strong wear resistance. Application Of Double Wall Corrugated Pipe Making Machine

1. The main machine adopts special designed high efficiency screw which is specially used for polyolefin,it has the features of

stable performance and high effiency.The machine has two independence extruders,which can realize both inside and outside layer

with different material and colors.

2. Composite extrusion die head with specially helical structure to make the wall thickness unifom and stable production.

3. The forming machine has automatic power-off protection device.The forming machine an automatically exit from the die head to

avoid equipment failure in case of electricity cut off suddenly.It also equipped with new type high transmitting ratio reducer,

easy to operate and mainteance.

4. The corrugated forming system is in combination with water cooling and air cooling to ensure high production speed

continuously.Advanced programmable lubricating system minimizes the moulds wear so as to increase the life of service and ensure

work smoothly with high precision to ensure the products quality stability.

5. Mould adopts specialy alumium alloy material and high precision die casting forming mould method,it has the advanages of high

precision,high stremgth,good wearability and better heat dissipation performance.

6. Wave structure launched a comprehensive new optimization design to reach the best combination of high-rigidity and low weight.

Qingdao Tongsan Plastic Machinery Co., LTD is a professional plastic extrusion machines manufacturer which stands by the Jiaozhou Bay. Converged with the national first-class scientific talests, our company is engaged in the study of new- type plastic machines and the conversion of international high-and -new technology. Cooperating with scientific research instifutions and institutions of higher education , we are converting the newest scientific payoffs at top speed. We will supply you the high-performance and high-tech plastic machines, Hollow sheet machine, Corrugated pipe machine, PVC and WPC foam board making machine.

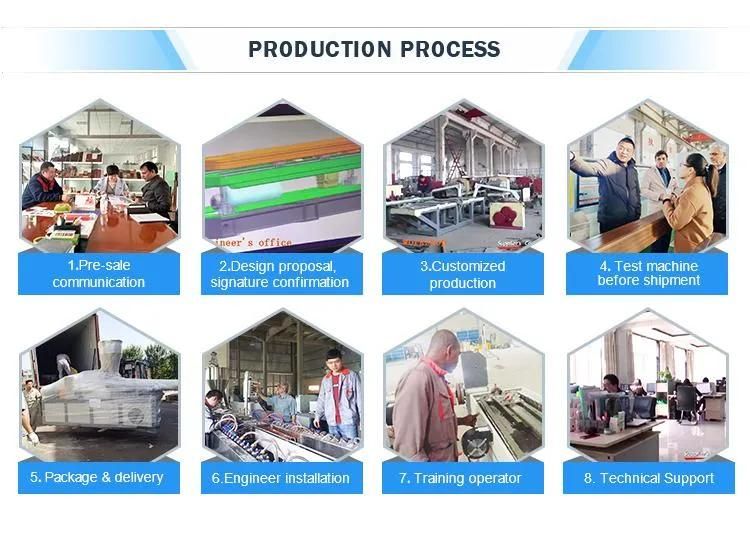

Packaging & Shipping

Fastening of fixed Steel Wire with plastic Film wound Wood Block

Our Services

- We will provide the Feasibility Analysis Report for the wood plastic project.

- We will provide the model selection and technical parameter for wood-plastic machine.

- We will provide the design for the plant and electric powder accounting for the facilities.

- We will provide the design for wood plastic formula according to the product requirement.

- We will provide the technology of wood plastic product surface treatment.

- We will provide technique training for operator.

- We will provide solution for the practical problem during the production.

- We will install and test machine for free.

- We will provide turnkey project to customers.

We look forward to have the opportunity to work together with you in the future.

Alan Jia