Servo Energy Saving Injection Molding Machine Hxm530

Ningbo Beilun Highsun Machinery Co., Ltd.- Warranty:24 Months

- Type:Plastic Injection Molding Machine

- Structure:Horizontal

- Plastic Type:PS,ABS,PP,PE,HDPE,PA,EVA

- Plasticizing Way:Screw Type

- Clamping Way:Hydraulic & Mechanical

Base Info

- Model NO.:HXM530

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Energy Saving:Servo Energy Saving

- After Sales Service:Engineers Avaiable to Service Machine

- Voltage:380,50Hz,According to Countries

- Showroom Locate:Malaysia,Russia,Turkey,Uzbekistan,Australia

- Injection Weight:1701g

- Space Between Tie Bar:860X810

- Machine Weight:19.7 Ton

- Transport Package:Standard Package

- Specification:8.1x2.14x2.5

- Trademark:Highsun

- Origin:China

- HS Code:8477101090

- Production Capacity:7000 Sets , Year

Description

Basic Info.

Model NO. HXM530 Automation Automatic Computerized Computerized Certification CE, ISO9001:2008 Energy Saving Servo Energy Saving After Sales Service Engineers Avaiable to Service Machine Voltage 380/50Hz,According to Countries Showroom Locate Malaysia,Russia,Turkey,Uzbekistan,Australia Injection Weight 1701g Space Between Tie Bar 860X810 Machine Weight 19.7 Ton Transport Package Standard Package Specification 8.1x2.14x2.5 Trademark Highsun Origin China HS Code 8477101090 Production Capacity 7000 Sets / YearProduct Description

1.Machine Feature:1. Super Energy Saving

Output power varies with the load, and no energy is wasted. In the holding pressure phase, the servo motor will reduce speed, with low energy consumption; during the cool-down period, the motor does not work, with zero power consumption. Compared with the ordinary injection molding machines, it can save 20%--80% of the power.

2. High Precision and High Stability

Equipped with the pressure sensor and rotary encoder, it can respectively monitor and feed back on flow and pressure. Based on the feedback, the high performance synchronous servo motor will adjust flow and pressure accordingly by changing the speed and torque. The closed-loop control can ensure the stability of product quality.

3. High Response and High Efficiency

The driving system responses with high sensitivity. It takes only 0.05 seconds to reach maximum value. The response speed is much faster than the ordinary injection molding machines. In that way, it significantly shortens the cycle time and increases the production efficiency.

2.Picture

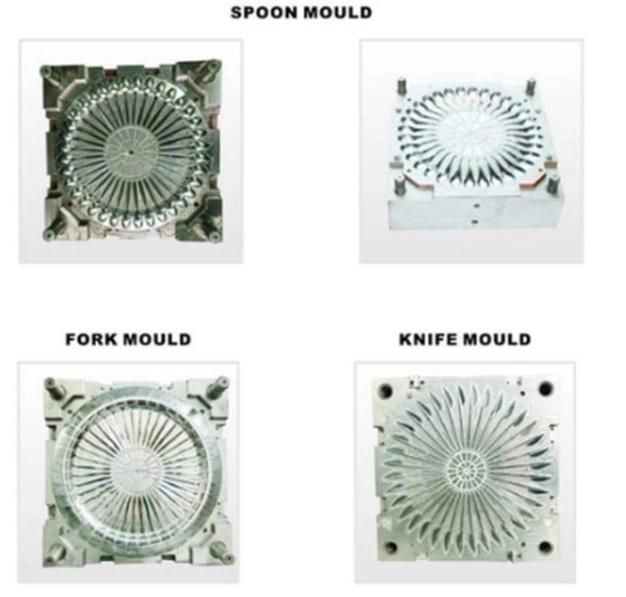

3.Application

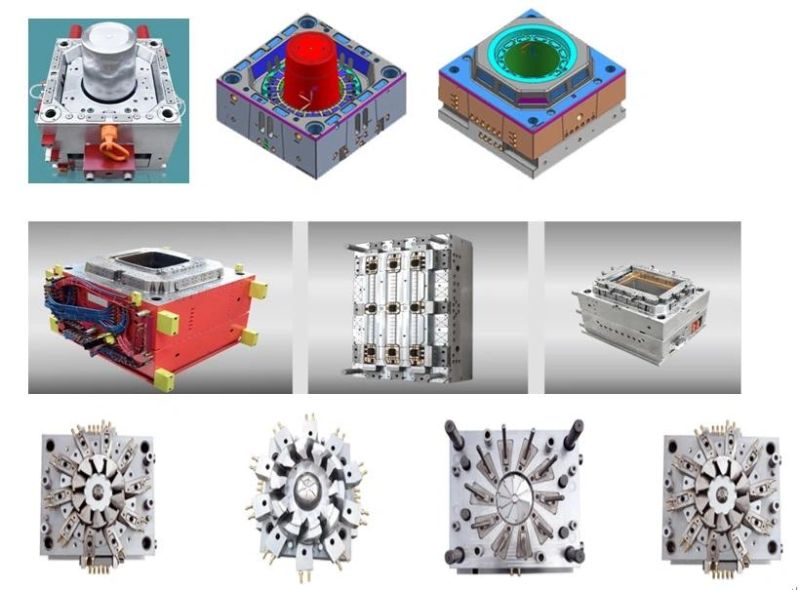

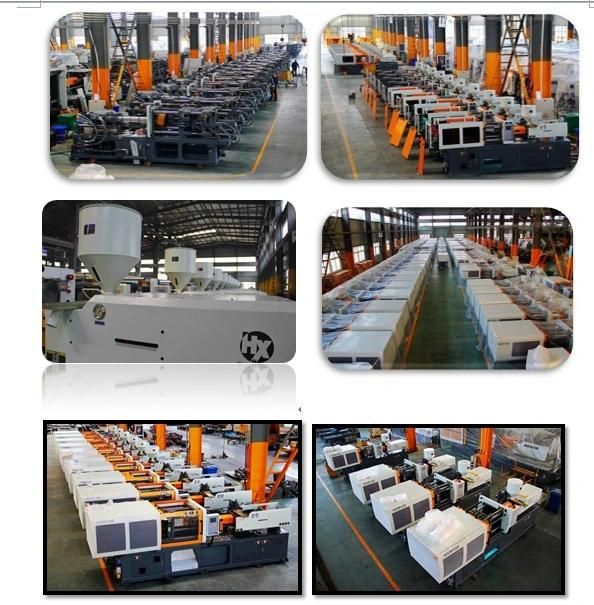

4.Processing,assembling production line

4.Processing,assembling production line

5.Loading containers

5.Loading containers

6. Customer case

Client in China produce shoe for Adidas

7.Client in Malaysia