Plastic Compounding&Granulating Parallel Twin-Screw Extruder

Jiangsu Beier Machinery Co., Ltd.- Type:Pipe Extruder

- Plastic Processed:PE

- Product Type:Granulating Extruder

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

Base Info

- Model NO.:TSK-20, TSK-35, TSK-50, TSK-65, TSK-75, TSK-95

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Automation:Automatic

- Computerized:Computerized

- Transport Package:Wood Pallet and PE Film

- Specification:ISO9001, CE

- Trademark:BEIER MACHINERY

- Origin:China

- HS Code:84772090

- Production Capacity:100sets,Year

Description

Basic Info.

Model NO. TSK-20, TSK-35, TSK-50, TSK-65, TSK-75, TSK-95 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Automation Automatic Computerized Computerized Transport Package Wood Pallet and PE Film Specification ISO9001, CE Trademark BEIER MACHINERY Origin China HS Code 84772090 Production Capacity 100sets/YearProduct Description

Tsk Series Parallel Twin-Screw ExtruderTSK Parallel twin-screw extruder is a kind of high-efficiency compounding and extruding equipment.

The screw & barrel adopt building block type design principle to change the length of the barrel, choose different screw stem parts to assemble the line according to material characteristics to get the best work condition and max function.

Because it has good mixing, separating, dewatering and self-cleaning functions to avoid the materials wrapping the axle, caking in the extruding process. With the rotation of the screw, the surface of the materials continuously change, helps the volatile matter dewater, treat, and etc.

Machine Design

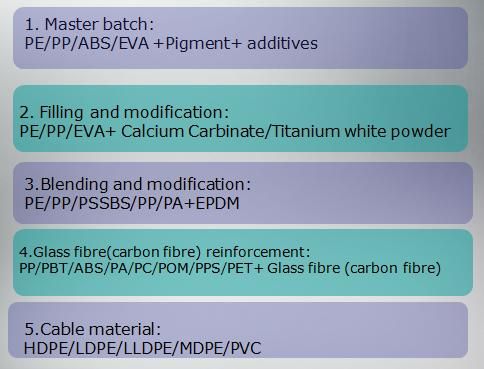

Usages of TSK Series Parallel Twin Screw Extruder

Four Kinds Compounding&Granulating Methods

1. Strand Pelletizing Line

2. Air-cooling Die-face Pelletizing Line

3. Water-ring Die-face Pelletizing Line

4. Under-Water Pelletizing Line

Technical Parameter

| Model | TSK-20 | TSK-35 | TSK-50 | TSK-65 | TSK-75 | TSK-95 |

| Screw diameter (mm) | 21.8 | 35.6 | 50.5 | 62.4 | 71.2 | 91 |

| L/D | 32-40 | 32-52 | 32/52 | 32/52 | 32/52 | 32/48 |

| Main motor (KW) | 3-4 | 15 | 37-45 | 55-75 | 90-110 | 220-280 |

| Max screw speed (rpm) | 600 | 600 | 500 | 500 | 500 | 400 |

| Capacity (kg/h) | 1.5-10 | 40-70 | 100-150 | 250-300 | 400-500 | 600-1000 |