Plastic Injection Molding Machine / PVC Shoe Making Machine for Sale

Henan Yugong Machinery Co., Ltd.- After-sales Service:Online Guidance

- Warranty:2 Years

- Type:Injection Blow Molding

- Structure:Vertical and Horizontal Composite

- Plastic Type:Thermoplastic

- Plasticizing Way:Screw Type

Base Info

- Model NO.:YG1J-16

- Clamping Way:Hydraulic

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Product Name:PVC Injection Molding Machine

- Application:Sports Shoes, Canvas Shoes, Casual Shoes

- Name:Shoes Injection Molding Machine

- Function:Making Shoes and Soles

- Raw Material:TPU,Tr,TPR,PVC

- Screw Diameter:75mm

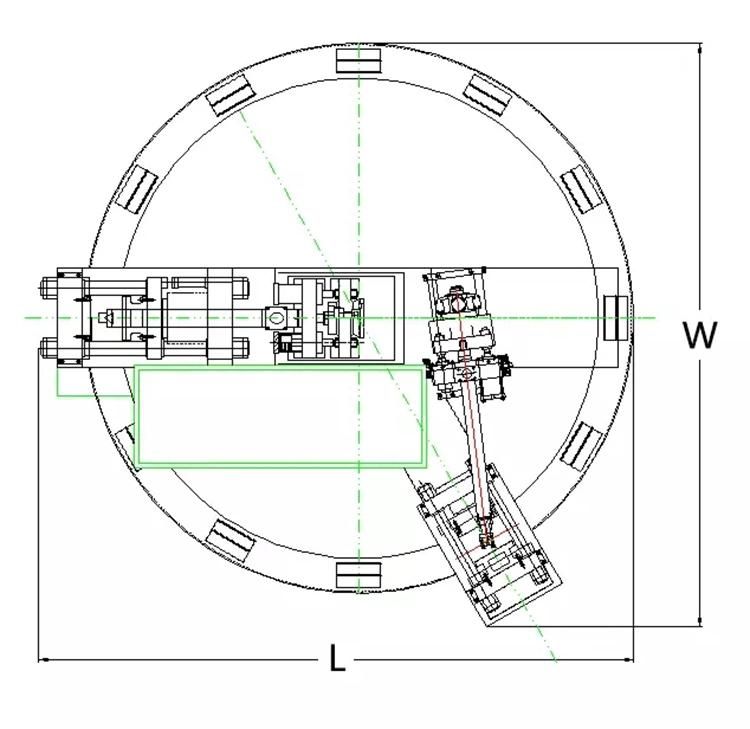

- Number of Station:16PCS, 20PCS, 24PCS

- Max Injection Capacity:660cm3

- Injection Pressure:5MPa

- Clamp Mould style:V

- Shoe Last Height:210-260mm

- Mould Frame Size:340*180*60mm

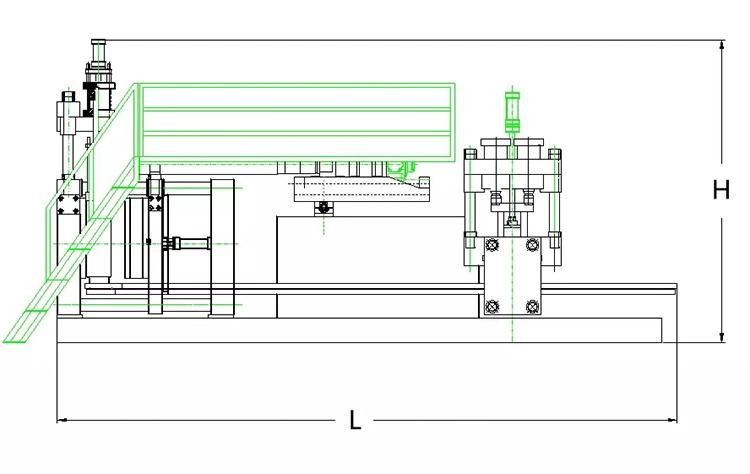

- Machine Size:6500*3200*2200mm

- Weight:9800kg

- Total:20.5kw

- Transport Package:40hq Container

- Specification:6500*3150*2150mm

- Trademark:YG,OEM

- Origin:China

- HS Code:84773090

- Production Capacity:100sets,Year

Description

The machine is injection moulding machine, can inject the material directly to mould and one-time molding, get the finished shoes. One machine is a production line, the finished products can directly sell. The machine need 1-2 workers to operate in production, the output is 80-100 pairs per hour for one color, 70-90 pairs per hour for two color, 60-80 pairs per hour for three colors.

Features

Features 1.PLC controlled, preplasticized by hydraulic motor, driven by full hydraulic pressure, and cycled automatically.

1.PLC controlled, preplasticized by hydraulic motor, driven by full hydraulic pressure, and cycled automatically.

2.High plastifying capacity, the plastifying temperaturecan be controlled automatically by preselection.

3.It adopts 12/16/24 points measuring and the injection volume can be chosen according to the requirements of the moulds at each working position.

4.The function of empty mould selection has been provided.

5.The round table is indexed by a frequency converter.

6.Parallel mould plate closing mechanism is adopted, which linked with a toggle system operated by single cylinder.

7.The machine is equipped with two time pressure injection system and the cramp pressing and mould closing order selecting function.

8.The round table indexes smoothly and it's movement can easily be adjusted.

9.The round table rotation, plasticizing and oil supply for the injection are controlled independently.

10.There are many working positions, the time for setting is long enough, and guarantees the setting quality of shoe soles.

Packaging & Shipping

Packaging & Shipping

Company Profile