Screw Segments and Barrel for Parallel Twin Screw Extruder Machine

Nanjing Tengda Machinery Co., Ltd.- Standard:Ce&ISO

- Technics:Forging

- Feature:Corrosion-Resisting

- Material:W6mo5cr4V2,38crmoala

- Application:Plastic Pellet

- Treatment:Nitriding Treatment

Base Info

- Model NO.:screw barrel

- Screw Hardness:HRC 58-62

- Heat Treatment:Vacuum Hardening

- Shaft Hardness:Hb 300-350

- Connection Method:Spline

- Screw Assembly:Modular Design

- Screw Speed:600rpm

- Processing Way:CNC

- Key Words:Screw and Barrel for Extruder

- Transport Package:Wooden Case

- Specification:W6Mo5Cr4V2 or38CrMoAl

- Trademark:TENDA

- Origin:Nanjing, Jiangsu

- Production Capacity:5000 Pieces,Month

Description

Basic Info.

Model NO. screw barrel Screw Hardness HRC 58-62 Heat Treatment Vacuum Hardening Shaft Hardness Hb 300-350 Connection Method Spline Screw Assembly Modular Design Screw Speed 600rpm Processing Way CNC Key Words Screw and Barrel for Extruder Transport Package Wooden Case Specification W6Mo5Cr4V2 or38CrMoAl Trademark TENDA Origin Nanjing, Jiangsu Production Capacity 5000 Pieces/MonthProduct Description

Screw Segments and Barrel for Parallel Twin Screw Extruder MachineAbout product

Different types of screw elements can be used in a twin screw extruder. Generally there are four major types of screw elements, namely conveying elements, kneading elements, backward-pumping elements and mixing elements. For each type there are many different subtypes.

Conveying elements

The geometry of the conveying elements enables a good transport of the product through the extruder. Each conveying element is characterized by its number of flights, its length in millimeters, and its pitch. The pitch is defined as the axial length in millimeters, required for a complete thread. Conveying elements with a large pitch have a greater conveying effect than those with a small pitch. These elements are used to forward the material e.g. at feed openings, in order to avoid that pressure increases excessively at the openings.

Kneading elements

Kneading elements are mostly used for dispersive mixing, but they are also used for distributive mixing processes. They consist of kneading discs with a certain thickness. Like the conveying elements there are several parameters by which the kneading elements are characterized. These parameters include the number of flights, the staggering angle between sequential kneading discs (in degrees), direction (clockwise or counter-clockwise) and the element length (in millimeters) .

Backward-pumping elements

Backward-pumping elements give a good distributive mixing and as the name implies they transport the product upstream instead of downstream. They are used for performing a more longitudinal homogenization.

Other screw elements

Product Show

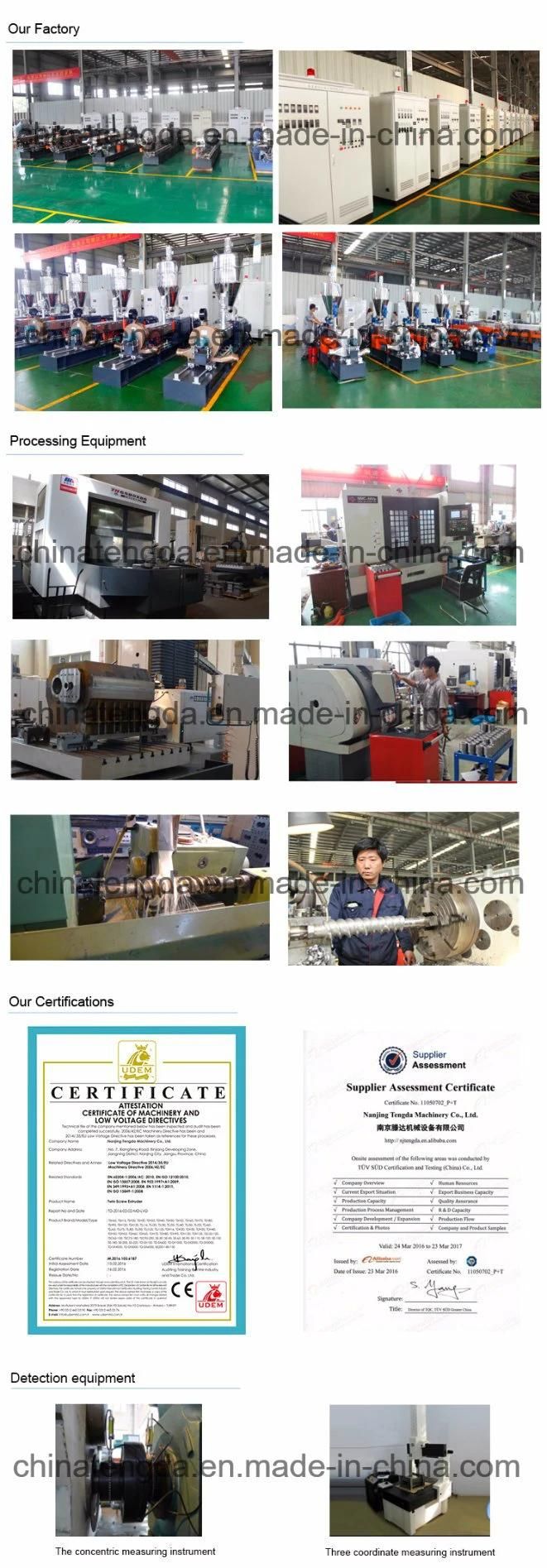

Our company

Tenda, headquartered in Nanjing, China, is a global manufacturing and trading company in the field of high performance plastics and rubber processing equipment, extrusion solutions, masterbatch and compounding, etc. Its unit Nanjing Tengda Extrusion Company is a professional manufacturer of twin screw extruder, single screw extruder, two stage extruder and its related auxiliaries. We tailor solutions from raw materials, materials processing equipment, to injection for different customers. Each Tenda's solution is designed, manufactured and commissioned by experienced teams of professionals engineers and after sales staffs.