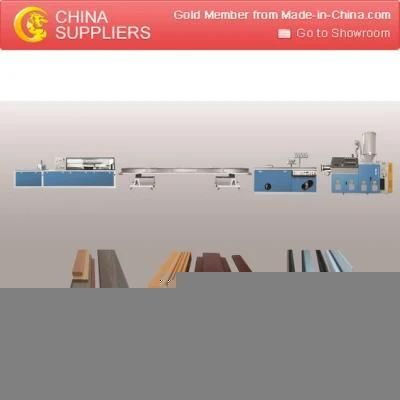

PS Foam Board Extrusion Production Line

GPM Machinery (Shanghai) Co., Ltd.- Product Type:Plastic Sheet

- Screw:Single-Screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Customized:Customized

Base Info

- Model NO.:GYF

- Product Name:PS Foamed Photo Frame Extrusion Line

- Processing Type:Profile Extrusion

- Raw Material:PS

- Usage:Picture or Photo Frame

- Motor:Simens

- Inverter:ABB Brand

- Contactor:France Schneider Contactors

- Temperature Control:Japan Omron

- Output:250- 450kg,H

- Motor Power:90kw-350kw

- Transport Package:PE Film Winding Wrapping

- Specification:5mm-50mm

- Trademark:GPM

- Origin:Shanghai

- HS Code:8477209000

- Production Capacity:500 Sets,Year

Description

SPECIFICATIONS FOR PS Foam Board Extrusion Production LineModel GYF-PS1 GYF-PS2 GYF-PS3 GYF-PS4 Extruder GW65 GW75 GW90 GW120 Co-extruder GW35 GW45 GW45 GW45 Products Width 3inch 4inch 5inch 6-8inch Speed 1-3m/min 1-3m/min 1-3m/min 1-3m/min

Main Features of PS Foam Board Extrusion Production Line:

GYF series PS Profile Extrusion Line, consists of single screw extruder and the special co-extruder, with the cooling water tank, hot stamping machine system, haul-off unit, and stacker. This line according to different profiles, surface and moulds to choose different standard twin parallel(conical) screw extruder.

Features of good plasticization, high output and stable performance etc. The hot stamping system combined foreign technology, by the hot stamping embossing method, transfer the coating layer from the film to the ps foamed profile. The machine with good appearance, stable performance, accurate & easy operation. By adjust the embossing wheel the machine can work on dfferent profiles. Working together with the main extruder and other extrusion down stream equipments, this line is popular as the latest developed production line.

For choosing the proper machine and saving your time, please read these bellow guides carefully

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the diameter of pipe(inch or mm); thickness of pipe wall(mm); width and thickness of profile(mm)? If profile product, you'd better offer the picture of sample or drawing of sample.

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.

Main Features of PS Foam Board Extrusion Production Line:

GYF series PS Profile Extrusion Line, consists of single screw extruder and the special co-extruder, with the cooling water tank, hot stamping machine system, haul-off unit, and stacker. This line according to different profiles, surface and moulds to choose different standard twin parallel(conical) screw extruder.

Features of good plasticization, high output and stable performance etc. The hot stamping system combined foreign technology, by the hot stamping embossing method, transfer the coating layer from the film to the ps foamed profile. The machine with good appearance, stable performance, accurate & easy operation. By adjust the embossing wheel the machine can work on dfferent profiles. Working together with the main extruder and other extrusion down stream equipments, this line is popular as the latest developed production line.

For choosing the proper machine and saving your time, please read these bellow guides carefully

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the diameter of pipe(inch or mm); thickness of pipe wall(mm); width and thickness of profile(mm)? If profile product, you'd better offer the picture of sample or drawing of sample.

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.