HDPE Thin Wall Pipe Black Casing Jacket Pipe Pre-Insulated Pipe Machine

Qingdao Huashida Machinery Co., Ltd.- Warranty:12 Months

- Product Type:PE Pipe

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:ISO9001:2008

Base Info

- Model NO.:PE-110,600

- Customized:Customized

- Condition:New

- After-sales Service:Available

- Production Method:Vacuum Calibration

- Needed Operator:2 Person

- Pipe Diameter:110-600mm

- Installed Power:160kw

- Dimension:26*3.5*3

- Transport Package:Standard Package

- Specification:ISO9001: 2008

- Trademark:HSD

- Origin:Qingdao China

- HS Code:8477209000

- Production Capacity:10 Units,Week

Description

Basic Info.

Model NO. PE-110/600 Customized Customized Condition New After-sales Service Available Production Method Vacuum Calibration Needed Operator 2 Person Pipe Diameter 110-600mm Installed Power 160kw Dimension 26*3.5*3 Transport Package Standard Package Specification ISO9001: 2008 Trademark HSD Origin Qingdao China HS Code 8477209000 Production Capacity 10 Units/WeekProduct Description

HDPE Thin Wall Pipe/Black Casing Pipe/Jacket Pipe/Pre-Insulated Pipe 110mm-600mm extrusion line/machine/extruder Vacuum CalibrationEFFICIENT INTELLIGENT HIGH QUALITY

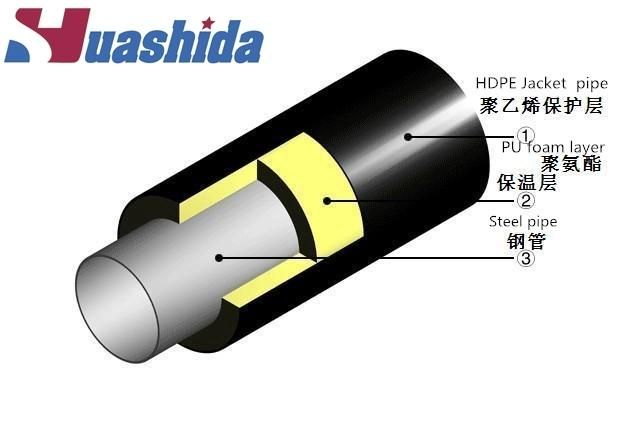

Production line of HDPE jacket pipe is high-efficiency equipment with high speed and energy saving for producing HDPE pipe used as a protective cover of PU foam thermal Pre-insulated Pipe according to international standard.

The HDPE jacket pipe is produced by vacuum calibrating method with smooth internal and external wall, long service life, good anti-corrosion insulation and mechanical performance.

---Pipe Application: the outer protective casing of PUF thermal insulated pipe, which is widely used in central heating, cooling oil&gas transmission and other industrial areas.

Features of Production line of HDPE jacket pipe

-small dimension

-high degree of automation, can be operated by one person, saving labor costs.

-long service life.

-high-efficiency extruder gives larger output, stable performance.

-pipe wall is average and smooth

-no waste of raw material

-once forming. No need trim edge.

Production line composition:

-1set Vacuum loader

-1set Hopper dryer

-1set High-efficiency single screw extruder

-1set Vacuum calibration table

-1set Hauling machine

-1set Cutting machine

-1set Discharging Frame

| Style | PE-110/600 | PE-365/760 | PE-655/1380 | PE-960/1680 | PE-1054/1860 |

| Main Extruder | SJ-75/33 | SJ-90/33 | SJ-120/33 | SJ-150/33 | SJ-150/33 |

| Pipe diameter | Φ110-600mm | Φ365-760m | Φ655-1380mm | Φ960-1680mm | Φ1054-1860mm |

| Capacity | 250-350kg/h | 400-500kg/h | 700-900kg/h | 1000-1200kg/h | 1000-1350kg/h |

| Installed power | 160kw | 240kw | 480kw | 580kw | 580kw |

| Length | 26m | 32m | 36m | 40m | 45m |

Workshop

Customers' inspection

Delivery

Welcome customers to visit our factory!