20L Round Square View Strip Lever Line Available Liquid Stocking Barrel Blow Molding ...

Zhangjiagang Dawson Machine Co., Ltd.- Type:Extrusion Blow Molding Machine

- Raw Material:HDPE

- Making Method of Parison:Extrusion-Blow Molding

- Automation:Automatic

- Computerized:Computerized

- Certification:CE

Base Info

- Model NO.:ABLD80

- Max. Product Volume:60L

- Application:Bottles, Jerry Cans, Toys, Tool Boxes, Coolers

- More Application:Plastic Oil Drums, Containers, Jerry Cans, Barrels

- Extrusion Type:Accumulation Type

- Parison Control:Moog 100 Points

- Hydraulic Motor:Servo Motor

- Robot System:Avaialble

- Die Head Heater:Plug Type

- Guarantee:1 Year

- Delivery Time:55 Days

- Screw:90 mm

- Max Die Mouth:280~340mm

- Clamping Force:210~260 Kn

- Max Mould Size:700X950mm

- Template Distance:450~1000mm

- Transport Package:Film Packaging

- Specification:ABLD90

- Trademark:DAWSON

- Origin:Jiangsu Zhangjiagang

- HS Code:8477301000

- Production Capacity:50~60 PCS,H

Description

Overview

Product Parameters

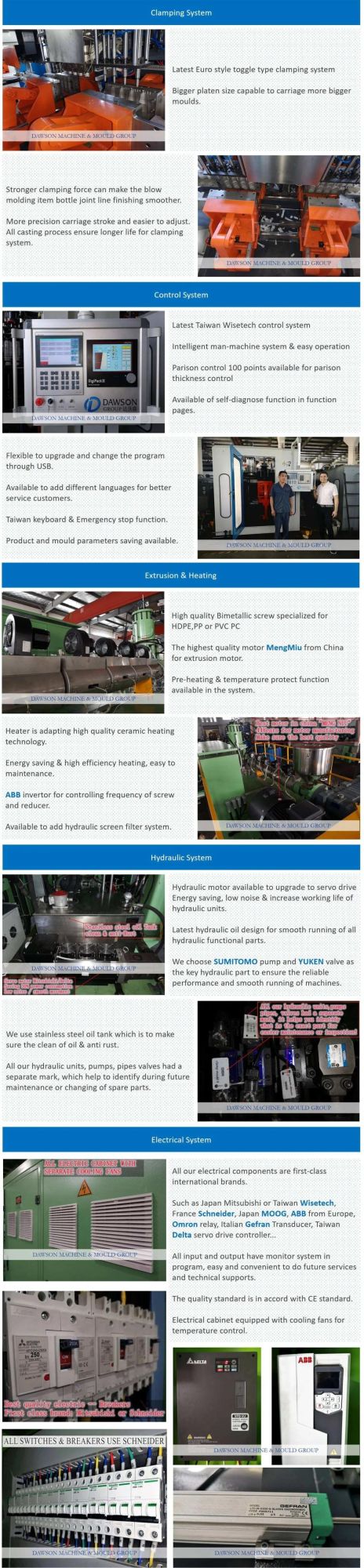

Basic parametersSuitable material PE.PP,PVC,PS,PETG,so on Max volume ABLD90 max: 60L Output capacity 40~50pcs/h Size 4.6×2.4×3.8(M) Weight 12T system Specification Parameters Note Plasticizion system Summarize High efficient low power consumption plasticizion system,transducer control,self-protect function when started at low temperature Reducer Hard finishing,High intension,Low noise reducer Screw ∮90mm,L/D ratio 25, 38CrMoALA Cooling system available Plasticization 100 ~ 130Kg/H HDPE Heating Zone 4 Aluminum Heater Automatic heating Heating power 15~18KW/H Extrusion Motor Three phase asynchronous motor (380V,50HZ) Cooling Fan 4zone Automatic cooling Extrusion system Summarize High-grade alloy steel, center feeding Die head number 1 Center distance of die heads / Max die mouth ∮280~340mm Heating zone 4 Stainless steel heating cycle Heating power 5~7KW Clamping system Summarize

High intension, rigidity, center mold locking, stable mould opening and clamping system Clamping force 210~260KN Template distance 450~1000mm Max mould size 700X950mm Mould material High grade 50# steel Electric system Summarize

PLC+ touch screen(man-machine interface)standard extrusion blow molding machine controlling system(AUTO monitoring, fault-alarm, auto counting ,auxiliary function available)

Japanese Mitsubishi PLC

system Operate interface Touch screen, automatic self-diagnose alarm system Temperature control Automatic temperature control module Movement control Japanese Mitsubishi, Chinese/English

Version Electric protection Ampere overload, electric short circuit self-protection function Hydraulic system Summarize Multiple function hydraulic integrated block Proportional control, high efficient Oil pump motor Three phase asynchronous motor (380V/220V,50/60HZ) Oil pump Imported double pump Valves Imported oil pump valves and connections Oil pipes Double layer overpressure resistant System pressure 60Kg/cm² Cooling system Separate water cooling cycle, oil cooler cooling system Pneumatic system Summarize Taiwan AIRTAC pneumatic system Air pressure 0.6Mpa Air displacement 0.8M3/min Electromagnetic valve Taiwan AIRTAC Cooling system Summarize Separate cooling system of mould, barrel and oil system Cooling medium Water Water flow 90L/min Water pressure 0.3-0.6MPa

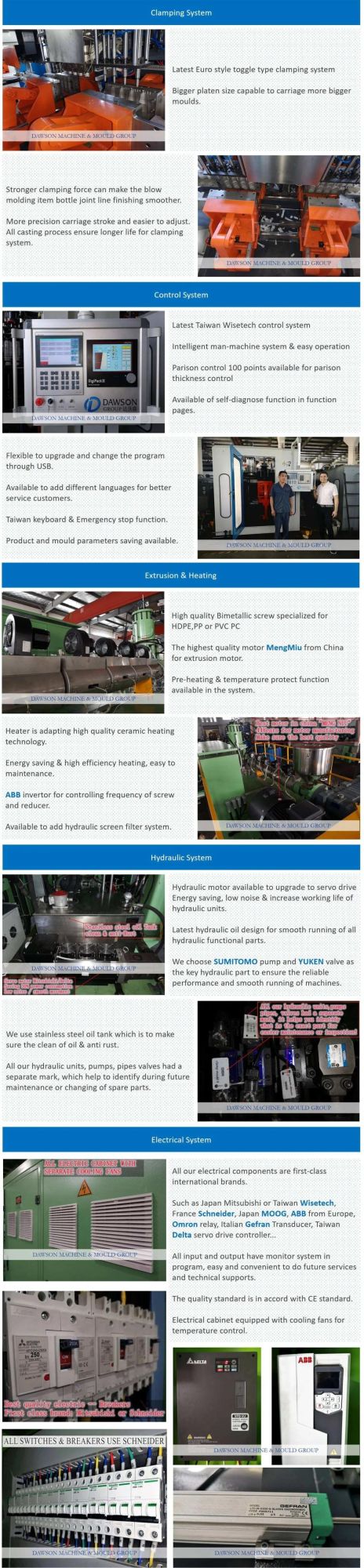

Detailed Photos

High quality mould

After Sales Service

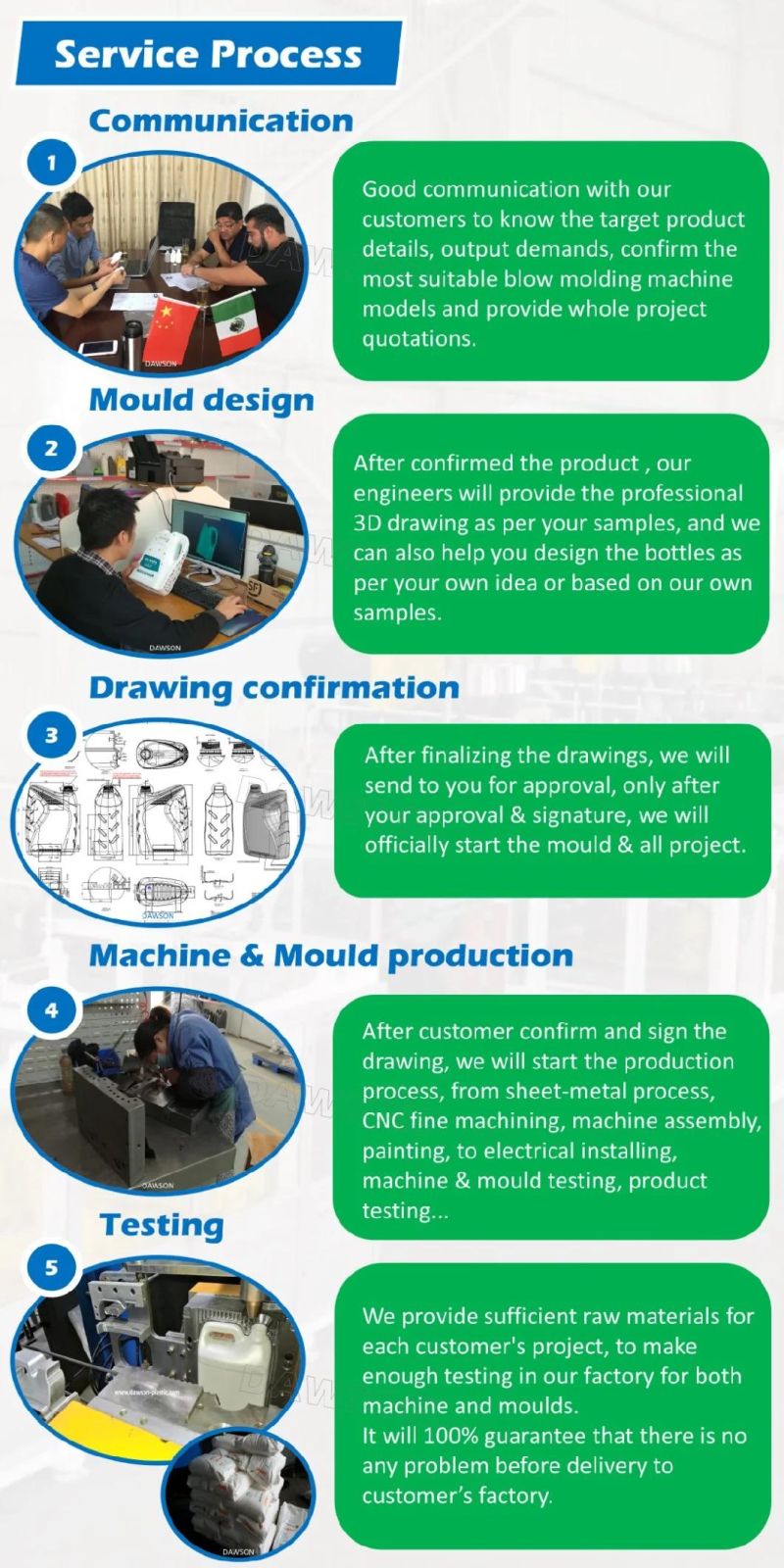

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong

International Airport. We can

pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with

quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical

support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers

products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the

customer's employees.

Q: What's DAWSON's advantage?

DAWSON provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we

can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save

a lot of cost and time.

DAWSON will be your reliable friend in China, and we will always do our best to give you max support!

Basic parameters

PLC+ touch screen(man-machine interface)standard extrusion blow molding machine controlling system(AUTO monitoring, fault-alarm, auto counting ,auxiliary function available)

Japanese Mitsubishi PLC

system

Version

Detailed Photos

High quality mould

Company Profile

Customer Feedback

After Sales Service

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong

International Airport. We can

pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with

quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical

support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers

products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the

customer's employees.

Q: What's DAWSON's advantage?

DAWSON provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we

can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save

a lot of cost and time.

DAWSON will be your reliable friend in China, and we will always do our best to give you max support!