Colorful Seaballs Double Station Blow Molding Machine

Zhangjiagang Dawson Machine Co., Ltd.- Type:Extrusion Blow Molding Machine

- Raw Material:PE

- Making Method of Parison:Extrusion-Blow Molding

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

Base Info

- Model NO.:DSB70

- Max Volume:7L

- Condition:New

- Screw Diameter:70mm

- Station Number:Double Station

- Guarantee Time:1 Year

- Delivery Days:60 Days

- Machine Lifespan:>20 Years

- Company Attribute:Manufacturer

- Screw L/D Ratio:24 L,D

- Power(W):28.5 Kw

- Machine Size:3.5X2.2X2.65 M

- Average Energy Consumption:30.5 Kw

- Machine Weight:6.5 Tons

- Voltage:Customer Specified

- After-Sales Service:Engineers Available to Service Machinery Overseas

- Transport Package:Nude Package,as Customers Request

- Specification:DSB70

- Trademark:DAWSON

- Origin:Zhangjiagang Jiangsu

- HS Code:8477301000

- Production Capacity:up to Product

Description

Basic Info.

Model NO. DSB70 Max Volume 7L Condition New Screw Diameter 70mm Station Number Double Station Guarantee Time 1 Year Delivery Days 60 Days Machine Lifespan >20 Years Company Attribute Manufacturer Screw L/D Ratio 24 L/D Power(W) 28.5 Kw Machine Size 3.5X2.2X2.65 M Average Energy Consumption 30.5 Kw Machine Weight 6.5 Tons Voltage Customer Specified After-Sales Service Engineers Available to Service Machinery Overseas Transport Package Nude Package/as Customers Request Specification DSB70 Trademark DAWSON Origin Zhangjiagang Jiangsu HS Code 8477301000 Production Capacity up to ProductProduct Description

DSB70 extrusion bottle blow molding machine was specially designed for making plastic water bottles, lubricant oil bottles, detergent bottles, plastic toys and other plastic containers not over 8L.

The features of this machine:

(1)It is suitable for producing PE, HDPE, PP, PVC, PETG, PS so on, plastic containers and bottles in all shapes are available, the max. Product volume is up to 8L.

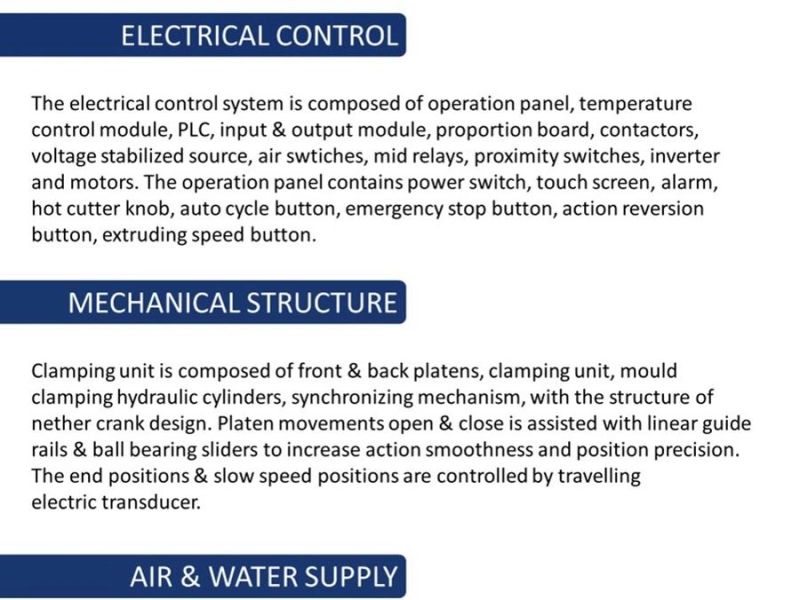

(2)Single station single die head design, very easy to operate and maintenance.

(3)Most components of the blow moulding machine are from famous world brand.

(4)Fully automatic process with low power consumption, high efficiency, quick and safe operation, easy for maintenance.

(5)Multiple screw available for double layer or tranparent liquid lever line.

(6)Auto deflashing device available, can remove the extra parts of bottles.

(7)Auto lubricant system controlled by PLC.

TECHNICAL DATA

| Machine Model | DSB70 |

| Max Product Volume | 7L |

| Target Material | LDPE/HDPE/PP/PVC/PETG |

| Machine Size | 3.5x2.2x2.65 m |

| Machine Weight | 6.5 Tons |

| Voltage Suitable | Customer Specified |

| Screw Diameter | 70 mm |

| L/D Ratio | 24:1 |

| Barrel Heating Power | 14.2 KW |

| Extrusion Motor Power | 22 KW |

| Plasticizing Capacity | 90 KG |

| Platen Size | 320x390 mm |

| Opening Stroke | 150~500 mm |

| Max Mould Size | 350x390 mm |

| Head No. | 3 |

| Central Distance | 110 mm |

| Heating Zone No. | 2+1 |

| Head Heating Power | 5.7 KW |

| Total Power | 52 KW |

| Average Energy Consumption | 30.5 KW |

| Compressed Air Needed | 0.6 Mpa / 0.8 m3 |

| Cooling Water Needed | 4.5 m3/H |

| Loading Reference | 20'GP |