Garbage Bottle Film Rubber Reprocessing Plastic Recycling Machine for Africa

ZHANGJIAGANG S&K MACHINERY CO., LTD.- Material Processed:Plastic Bottle

- Plastic Type:PET

- Automation:Automation

- Computerized:Computerized

- Certification:ISO9001:2008, CE

- Name:Plastic Waste Recycling Plant

Base Info

- Model NO.:SK500

- Capacity:300-2000kg,Hour

- Delivery:45working Days

- Payment:T,T L,C

- Voltage:380V 50Hz

- Final Size:3-4mm

- Warranty:1 Year

- Weight:8-15tons

- Power(W):150-500kw

- After-Sales Service:Engineers Available to Service Machinery

- Color:Customer Choice

- Keywords:Plastic Recycling Machine

- After-Sale:Engineer Will Go and Install The Machine

- Transport Package:Film or Wooden Case

- Specification:5000x4500x3000mm

- Trademark:S&K

- Origin:China

- HS Code:84778000

- Production Capacity:80sets,Year

Description

Basic Info.

Model NO. SK500 Capacity 300-2000kg/Hour Delivery 45working Days Payment T/T L/C Voltage 380V 50Hz Final Size 3-4mm Warranty 1 Year Weight 8-15tons Power(W) 150-500kw After-Sales Service Engineers Available to Service Machinery Color Customer Choice Keywords Plastic Recycling Machine After-Sale Engineer Will Go and Install The Machine Transport Package Film or Wooden Case Specification 5000x4500x3000mm Trademark S&K Origin China HS Code 84778000 Production Capacity 80sets/YearProduct Description

Garbage bottle film rubber reprocessing plastic recycling machine for africa

Technical Features:

1. High automation level, try best to reduce your cost on labor(especially for three shifts)and ensure high processing capacity: 100-2000kg/hr.

2. Friendly control system(PLC integrated & separated control on each machine)and Touch screen panel, easy for operation, monitor and emergency stop.

3. All parts contacting with plastic material and water are made of high-quality 304 stainless steel; ensure no second pollution to flakes.

4. This China Hot Selling Waste PET Bottle Washing Machine can easily wash and recycle waste PET bottle flakes. Equipment at the end of the washing line so that the completely dry flakes can be collected and packed directly after being washed.

5. The whole production line can be designed on the basis of how dirty the flakes are, and make sure of the quality of the final products.

6. Coordinating the production line with follow programmed work (granulating system), and it will make waste and dirty PET bottles to be the PET granule material and in order to producing new PET bottles.

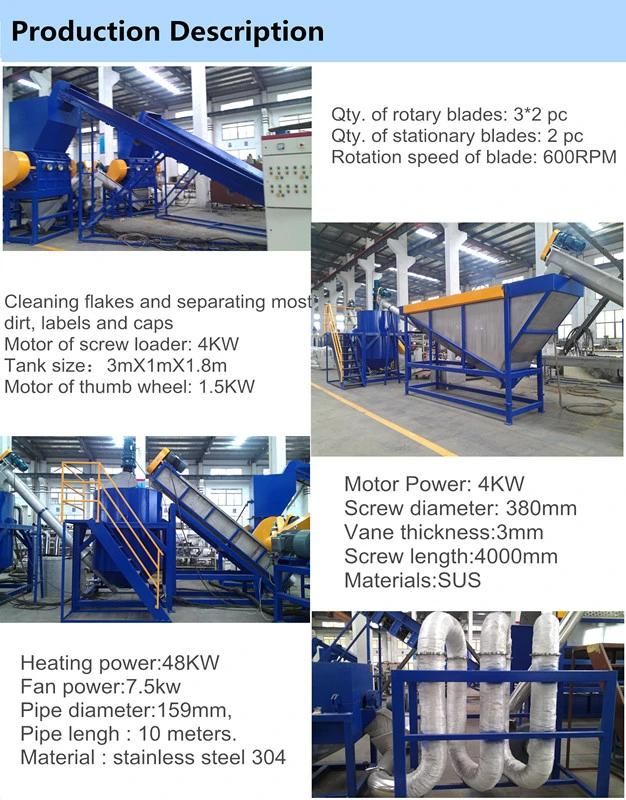

Product Description:

Raw Material :

Bottles jars and other containers made of PET can be collected and recycled into a wealth of products. PET can be recycled into new PET bottles and containers, carpet and clothing, industrial strapping, rope, upholstery fabrics, boat sails, automotive parts, fibrefill for winter jackets and sleeping bags, construction materials, and many other items.

| Product Name | Plastic film/bags washing recycling machine/line/equipment/Plant |

| Model | SK-300,SK-500,SK-1000,SK-1500 |

| Capacity | 300kg/h ,500kg/h,1000kg/h ,1500 Kg/h or customized it |

| Warehouse/Workshop | Dimension (M*M*M): 40(L)×8(W)×3.8(H); |

| Install power | 170KW~400KW |

| Water supply | 10-12 tons per hour recycling water (actual consumption is 0.5 ton/h). |

| Cooling water | 20ºC |

| Moisture content | 5~8%,after hot air dryer ,<1% |

| Power supply | 3*380V 50HZ or customized |

| Manpower | 3 Persons (one for material input, one for granules packing) |

| Delivery time | 45-60working days |

| Spare parts | Support |

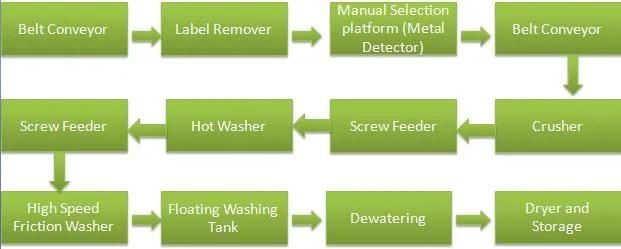

Production Flow

Our workshop

Packing&Shipping

Packing: Film covered or wooden box package(According to customer needs )

Delivery: 45-60 working days

Port: Shanghai port

Our Certification:

Our exhibition :

Participated in various exhibitions at home and abroad , Like Chinaplas, Thailand-plas, Malaysia-plas Indonesia-plas,and so on .

FAQ

1. Q: Are you manufacture factory or a trader?

A: We are an industrial manufacture factory of plastic recycling machinery for years, which locates in Zhangjiagang city, China.

2. Q: What's your payment term:

A: T/T 30% in advance & T/T 70% upon sending the copy of Bill of Lading, L/C 100%, or negotiate according to the order status.

3. Q: Can we visit your factory ?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case

4. Q: How do you make the quotation for clients?

A: The price depends on quality and performance but the clients should be satisfied first.

5. Q: Do you have any after-sale service ?

A: Yes,we have professional after-sale teamwork . any technical question could be solved in 24 hours by our after-sale teamwork.

6. Q: How do you install your equipment in our factory ?

A: We have professional after-sale &installation teamwork, we will arrange our engineer fly to ur factory install and teach ur labor .

Our company

S&K Machinery is a high-Tech company who is specializing in the R&D. The main products of S&K are :

- PP PE film/PET bottle pelletizing machine

- PP PE film/PET bottle recycling washing machine

- Plastic shredder /crusher /mixer strirrer and so on.

Each of these recycling machine can help the plastic industry to be high efficient , enenrgy saving, convenient and environment protection.

S&K Machinery,With its professional technical support and all full range service, is creating the new ,energy saving,high quality,high precision and high reliability machines with the help of the customers.