High Quality WPC Composite Door Extrusion Machine

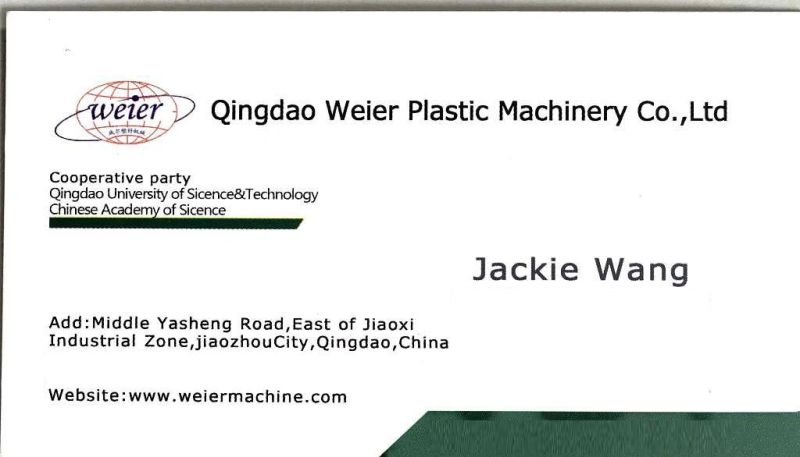

Qingdao Weier Plastic Machinery Co., Ltd.- Type:Door Panel

- Plastic Processed:Wood Powder+PVC Resin

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

Base Info

- Model NO.:SJSZ-92,188

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Transport Package:Export Package

- Specification:CE, SGS, ISO9001

- Trademark:weier

- Origin:Qingdao, China

- HS Code:84772090

- Production Capacity:50 Units Per Year

Description

Basic Info.

Model NO. SJSZ-92/188 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Transport Package Export Package Specification CE, SGS, ISO9001 Trademark weier Origin Qingdao, China HS Code 84772090 Production Capacity 50 Units Per YearProduct Description

WOOD-PVC composite door panel extrusion machineryWPC hollow door production line

Qingdao Weier Plastic Machinery Co., Ltd is a professional supplier of various plastic extrusion machines.

Our company is cooperating with many universities to develop the urgently needed plastic machine. It also absorbs advanced technology from abroad to achieve the purpose of supplying complete machine and technology

WPC Wood-plastic Door Extrusion Line

WEIER series of wide plastic sheet production line mainly used: PVC + wood flour. Production overall door, construction and other wood-plastic plate Templates before the extrusion. The line I use the original wood-plastic technology companies and formula. Plates can be based on different sections, according to the different uses of sheet metal, product design different proportions. Selection of different specifications for the wood-plastic twin-screw extruder, and wood-plastic for single screw extruder, and the corresponding vacuum stereotypes targeting Taiwan, traction machines, horizontal cutting machine, expected over platforms such as auxiliary equipment. Replacement of a different mold can produce different specifications of the plastic sheet. Traction for the company I used a unique technology, steady work, good reliability, great traction. Increase the use of special vacuum stereotypes swirl cooling system, to facilitate cooling stereotypes, to meet the wide wood-plastic plate to the needs of the production features. Cutting sheet metal device with the horizontal speed traction to keep pace, design reasonable, stable operation, can automatically

| model | MSYF600 | MSYF1000 | MSYF1300 |

| extreme breadth(mm) | 600 | 1000 | 1300 |

| auxiliaries gross power(kw) | 30 | 50 | 55 |

| cooling water capacity(m3/h) | 10 | 12 | 14 |

| pneumatic pressure(MPa) | 0.6-0.7 | 0.6-07 | 0.6-0.7 |