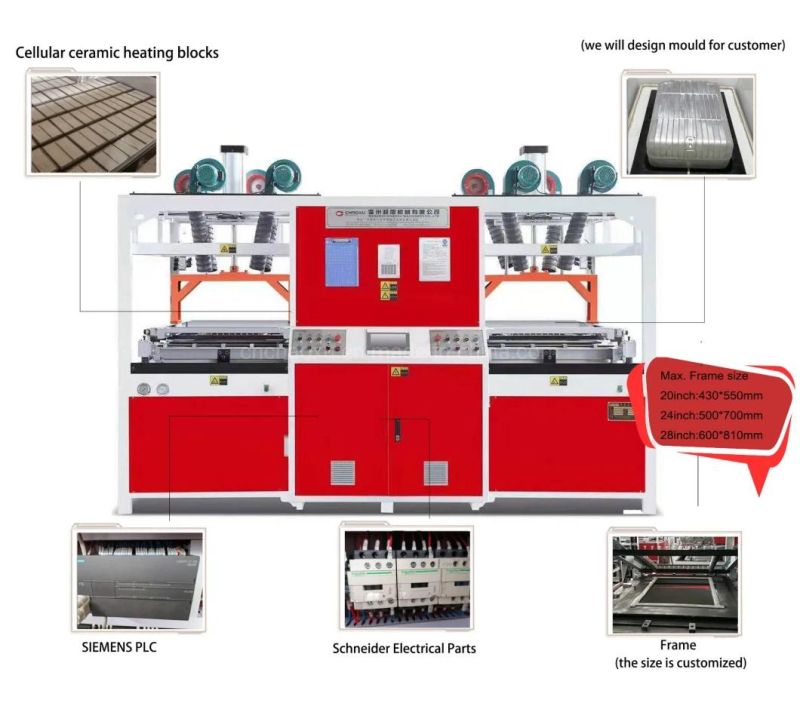

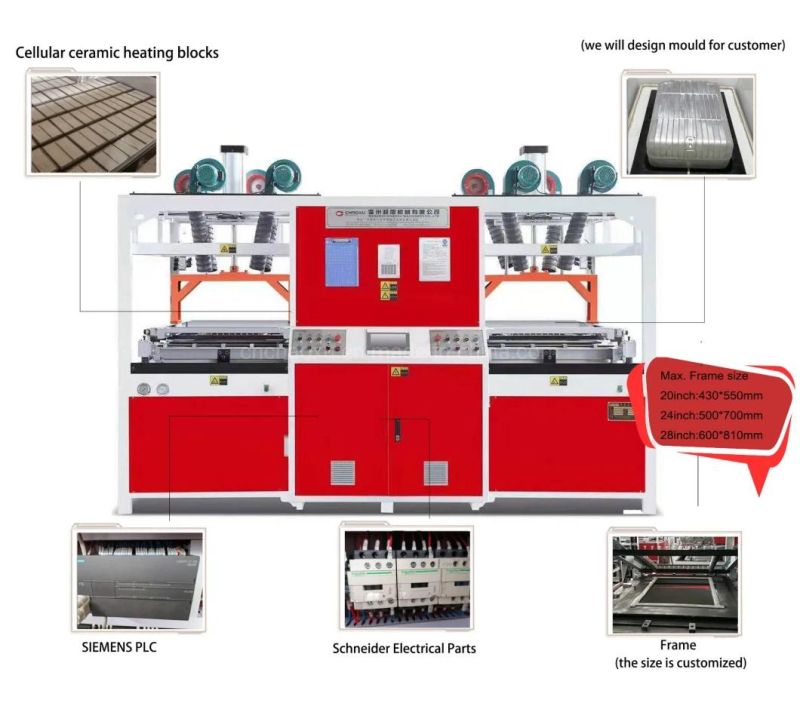

Chaoxu Small Air Bubble Machine Luggage Production Line

Wenzhou Chaoxu Machinery Co., Ltd.- Automation:Automatic

- Shaping Mode:Die Molding

- Driven Type:Pneumatic

- Computerized:Computerized

- Sheet Thickness:1-4mm

- Input Power:380V

Base Info

- Model NO.:YX-24A

- Vacuum Pressure:0.07-0.09MPa

- Air Pressure:0.65-0.75MPa

- Air Consumption:650L , Min

- ABS Case Max. Output:105PCS , H

- PC Case Max. Output:80PCS , H

- Machine Weight:2.2t

- Forming Dimension:690*510*200mm

- Material:ABS PC etc.

- Transport Package:Wooden Case,Wooden Pallet Packing

- Specification:3180*1860*2410mm

- Trademark:CHAOXU

- Origin:Zhejiang, China

- HS Code:8477409000

- Production Capacity:50 Set,Month

Description

0.65-0.75Air consumption L / MIN 550 650 800 Weight T 2 2.2 2.5 Total Power KW 40 49 57 Forming Dimension MM 600*420*200 690*510*200 780*600*200 Overall Dimension MM 2880*1760*2410 3180*1860*2410 3480*1960*2440

Machine Feature:

1)Two working modes. Automatic and Manual working modes can be chosen by customers.

2)Two Chambers. The left and right stations can work by turns to save time and provide productivity.

3)PLC screen. The operation interface is compact and easy to operate, the paraments can be adjusted and saved in real time.

4)Preheated system. Sheets can be preheated automatically to save power and time.

5)Heaters. All heaters are controlled separately and easy to be adjusted.

6)Silent technology. Machines can move and work silently.

7)Cooling system. Customers can change the cooling direction according to the situation.

Application:

About Us:

Wenzhou Chaoxu Machinery Co.,ltd has specialized in Intelligent Luggage Machinery Industry since 1992.

We became a leading brand after two decades' development and management, having a group of senior technical team. Our main products are Plastic Sheet Extrusion Machine, Vacuum Forming Machine, Cutting Machine, Punching Machine and so on.

In addition, we have researched and achieved lots of national technical patents: for example: Cursor positioning device in cutting component Mold distributor device and Water film temperature machine device for Extrusion Machine

Lifting frame device and Drying oven device for Vacuum Forming Machine

Also, we processed CE, ISO9001:2015 certificates and owned the whole running system.

Meanwhile, we are cooperating with global famous luggage manufacturers such as Samsonite, Crown and having further relationship with suppliers ABB, Schneider, Siemens, Taiwan Weinview, Japan ORMON and so on. Our machines are sold well among Western Europe, Middle East, Southeast Asia and other more than 20 countries and regions.

Exhibition:

Packing&Shipping:

Certificate:

FAQ:

Q1:Are you a factory or a trading company? A1:We are the manufacturer and factory, specialized in luggage machinery industry since 1992.

Q2:Where is your factory? How can I get there?

A2:Our factory is located in Pingyang County, Wenzhou City, Zhejiang Province, China.

Q3:What's your main market?

A3:Our machine is sold well in 30 provinces and cities and enjoy high reputation in China. At the same time,

it has been widely exported to more than 20 countries, such as Turkey, Morocco, India, Bangladesh, Algeria, Egypt, Tunisia, South Africa, Vietnam, Cambodia, Thailand, Germany, Indonesia, Lebanon, Pakistan, Brazil, Russia, etc.

Q4:How is your factory doing in quality control?

A4:Quality is the most important principle. There are at least twice test before shipment, the first is by our factory, the second is together with customer. Thus our customers will know well about how to use the machine before it arrives at their factory. And also we will offer whole-life service. What's more, all machinery has been passed ISO and CE testing. Strictly testing the machine and arranging delivery after 100% confirmation of no problem are what we always do.

Q5:How about after sales service?

A5:During the special period of COVID-19, we will offer all support online via video 24h per day. Before shipment, we will test machine from A to Z, and then send all videos from installation to production for customers. Full set of manual and instruction in English will be sent with machine together. And if customers need the engineer to offer support in their factory, the cost and visa should be paid and prepared by customers.

Machine Feature:

1)Two working modes. Automatic and Manual working modes can be chosen by customers.

2)Two Chambers. The left and right stations can work by turns to save time and provide productivity.

3)PLC screen. The operation interface is compact and easy to operate, the paraments can be adjusted and saved in real time.

4)Preheated system. Sheets can be preheated automatically to save power and time.

5)Heaters. All heaters are controlled separately and easy to be adjusted.

6)Silent technology. Machines can move and work silently.

7)Cooling system. Customers can change the cooling direction according to the situation.

Application:

This machine is suitable for forming of such sheet as ABS,PC or recycled material.It is special for processing luggage/trolley case shell professionally with fast speed and high quality.

The YX-A series is provided with automatic separated frame operation and upper-lower double heating with PLC intelligent control system.Machine can be customized as customer requirement.

About Us:

Wenzhou Chaoxu Machinery Co.,ltd has specialized in Intelligent Luggage Machinery Industry since 1992.

We became a leading brand after two decades' development and management, having a group of senior technical team. Our main products are Plastic Sheet Extrusion Machine, Vacuum Forming Machine, Cutting Machine, Punching Machine and so on.

In addition, we have researched and achieved lots of national technical patents: for example: Cursor positioning device in cutting component Mold distributor device and Water film temperature machine device for Extrusion Machine

Lifting frame device and Drying oven device for Vacuum Forming Machine

Also, we processed CE, ISO9001:2015 certificates and owned the whole running system.

Meanwhile, we are cooperating with global famous luggage manufacturers such as Samsonite, Crown and having further relationship with suppliers ABB, Schneider, Siemens, Taiwan Weinview, Japan ORMON and so on. Our machines are sold well among Western Europe, Middle East, Southeast Asia and other more than 20 countries and regions.

Exhibition:

Packing&Shipping:

Certificate:

FAQ:

Q1:Are you a factory or a trading company? A1:We are the manufacturer and factory, specialized in luggage machinery industry since 1992.

Q2:Where is your factory? How can I get there?

A2:Our factory is located in Pingyang County, Wenzhou City, Zhejiang Province, China.

Q3:What's your main market?

A3:Our machine is sold well in 30 provinces and cities and enjoy high reputation in China. At the same time,

it has been widely exported to more than 20 countries, such as Turkey, Morocco, India, Bangladesh, Algeria, Egypt, Tunisia, South Africa, Vietnam, Cambodia, Thailand, Germany, Indonesia, Lebanon, Pakistan, Brazil, Russia, etc.

Q4:How is your factory doing in quality control?

A4:Quality is the most important principle. There are at least twice test before shipment, the first is by our factory, the second is together with customer. Thus our customers will know well about how to use the machine before it arrives at their factory. And also we will offer whole-life service. What's more, all machinery has been passed ISO and CE testing. Strictly testing the machine and arranging delivery after 100% confirmation of no problem are what we always do.

Q5:How about after sales service?

A5:During the special period of COVID-19, we will offer all support online via video 24h per day. Before shipment, we will test machine from A to Z, and then send all videos from installation to production for customers. Full set of manual and instruction in English will be sent with machine together. And if customers need the engineer to offer support in their factory, the cost and visa should be paid and prepared by customers.