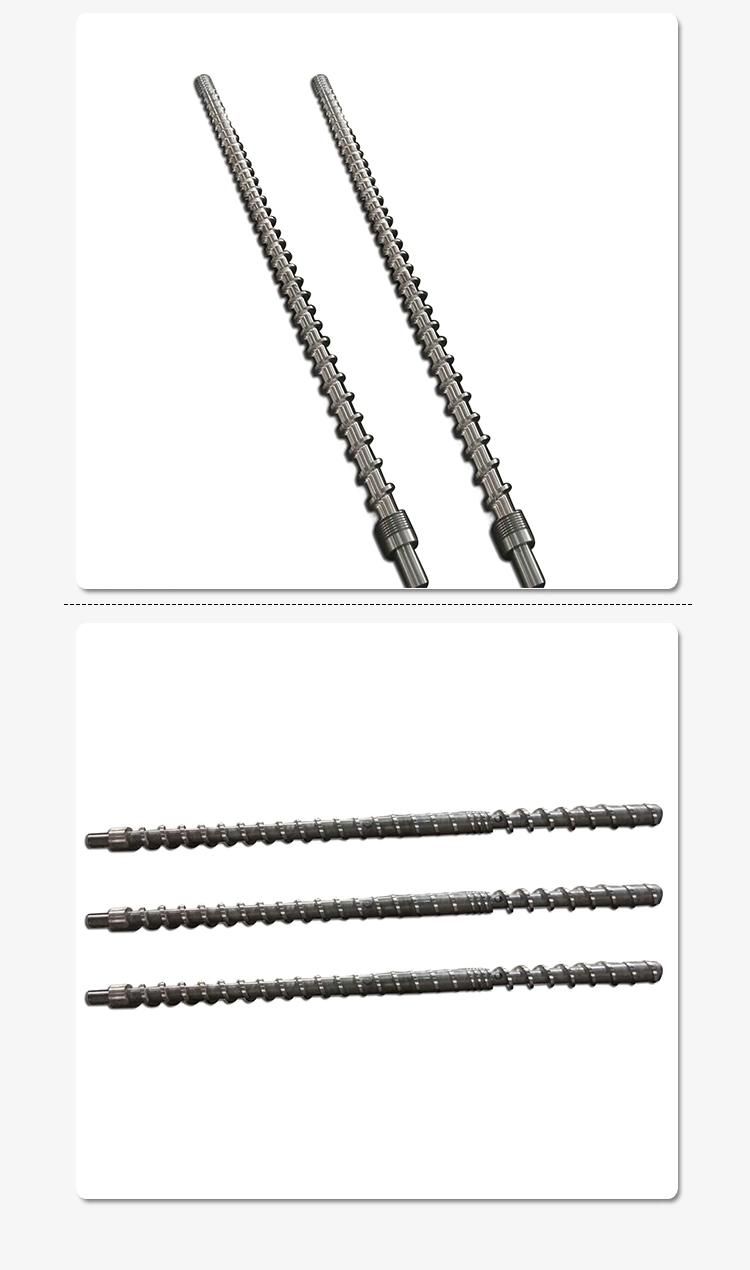

Screw Barrel Plastic Machine for PE Pellet

Zhejiang Pinbo Plastic Machinery Co., Ltd.- Material:Plastic

- Type:Profile Extruder

- Screw:Twin-Screw

- Automation:Automatic

- Computerized:Computerized

- Plastic Processed:PVC

Base Info

- Model NO.:double screw barrel

- Brand Name:Pym

- Base Material:38crmoaia, 42CrMo

- Certificats:CE BV SGS Tvu

- Delivery:25days

- Heating-Treatment:Nitrogen, Electroplated Hard-Chrome Finshed etc

- Transport Package:Packed in Wooden Case.

- Specification:CE SGS BV TUV

- Trademark:pym

- Origin:Wenzhou, Zhejiang, China

- HS Code:847790000

- Production Capacity:300set,Sets Per Month

Description

Basic Info.

Model NO. double screw barrel Brand Name Pym Base Material 38crmoaia, 42CrMo Certificats CE BV SGS Tvu Delivery 25days Heating-Treatment Nitrogen, Electroplated Hard-Chrome Finshed etc Transport Package Packed in Wooden Case. Specification CE SGS BV TUV Trademark pym Origin Wenzhou, Zhejiang, China HS Code 847790000 Production Capacity 300set/Sets Per MonthProduct Description

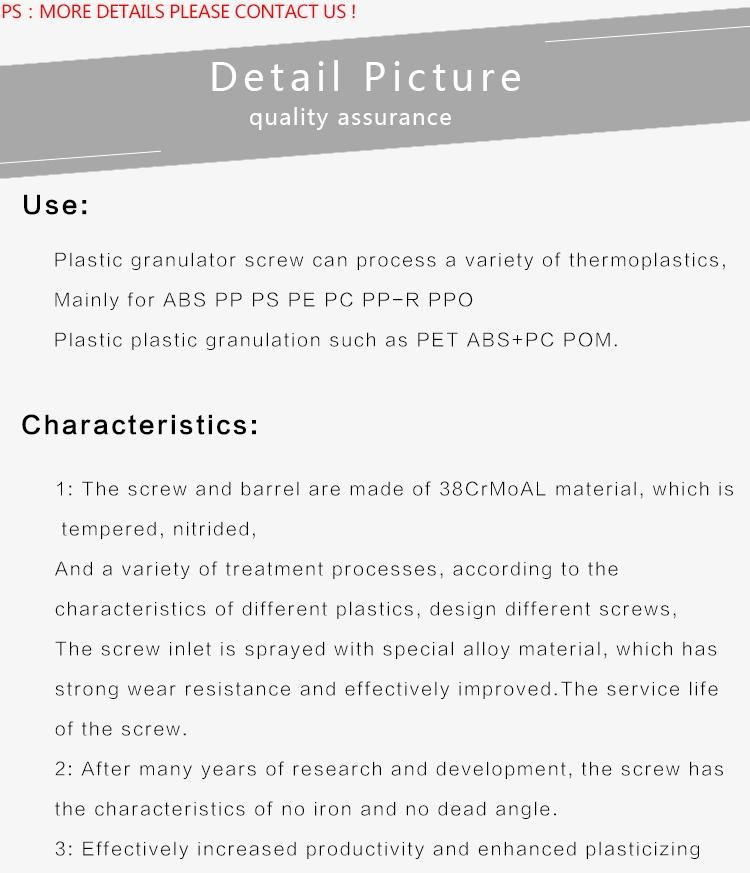

For bimetallic screw ,we have adopted advanced technique(HP/HVOF)of surface harden Process by the whole screw surface,WPT1 alloy with corrosion resistant suits for nylon,PVC,PC,PMMA and so on.WPT2alloy corrosion resistant and high temperature resistant Suits for magnetic power ,maanetic powder,magnesium and alumimum powder.Bakelite injection and so on .WPT3 is compatible with WPT1 and WTPT2.

For bimetallic barrel ,we have raised the proportion of tungsten contained in alloy to 30%and 50%from previous10%,and we also have increasedthe processing length to 4000mm from the previous length of 3000mm.

The main advantage of screw barrel:

a. Advanced Nitriding Technology

b. Anti-corrosion and Wear-resisting Duplex Metal Spraying Technoloy

c. we uses special alloy powders being sprayed and welded on the screw's ridge,and uses different alloy and welding methods for the screw of different functions.

Why choose us ?

A> long time experience and history

B> long time nitriding treatment and heating treatment by itself

C>advanced Fanuk series CNC computer-controlled milling machines

D>depth hole drilling machine in 10meters length, which ensure the straigtnss of barrel inside.

E> CAD drawing confirmation before start making

F> Prompt after sale service

G>Land owner and registration capital 25,000,000RMB

Welcome to visit our company !

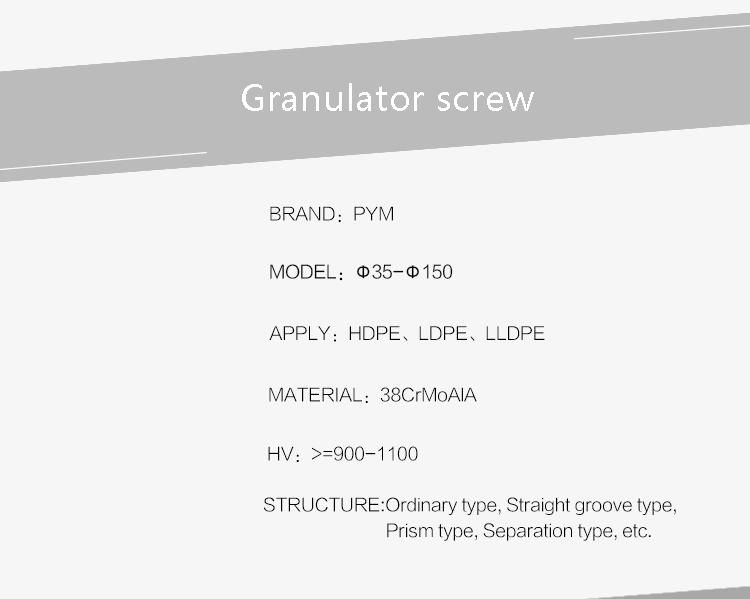

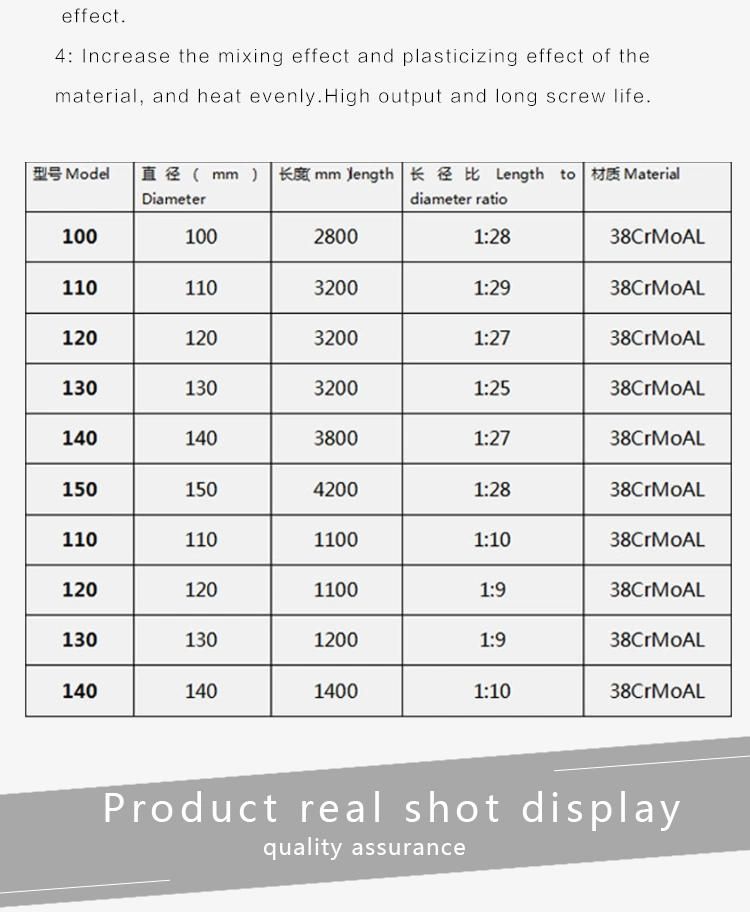

| Product | screw barrel for pellet |

| Material | 38 CrMoAlA(JIS SACM645); 42 CrMo(JIS SCM440) |

| Hardness of nitrogen treatment | HV900°~1100° |

| Tempering hardeness | HB240 ° ~280° |

| Depth of nitrogen layer: | 0.6~0.8mm |

| Nitrided Brittleness | above 1 stage |

| Surface Roughness | Ra0.4 um |

| Screw straightness | 0.015mm |

| Hardess of surface chromium-plating after Nitriding | HV≥950HV |

| Chromium plating Depth | 0.025-0.085mm |

| Alloy Depth | 2.5mm-4mm |

| Alloy hardness | HRC62°~72° |

| Heating-treatment | nitrogen ,electroplated hard -chrome finish,high frequency quenching |