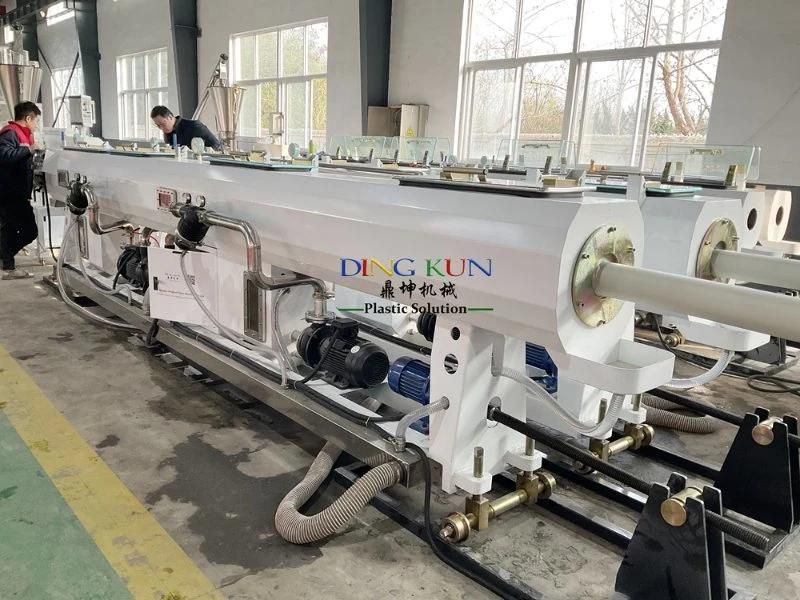

Automatic Plastic PVC Electric Conduit Tube Pipe Making Machine

QINGDAO DING KUN PLASTIC MACHINERY CO., LTD.- Product Type:PVC Pipe

- Screw No.:Double-screw

Base Info

- Model NO.:SJSZ 80,156

- Automation:Automatic

- Computerized:Computerized

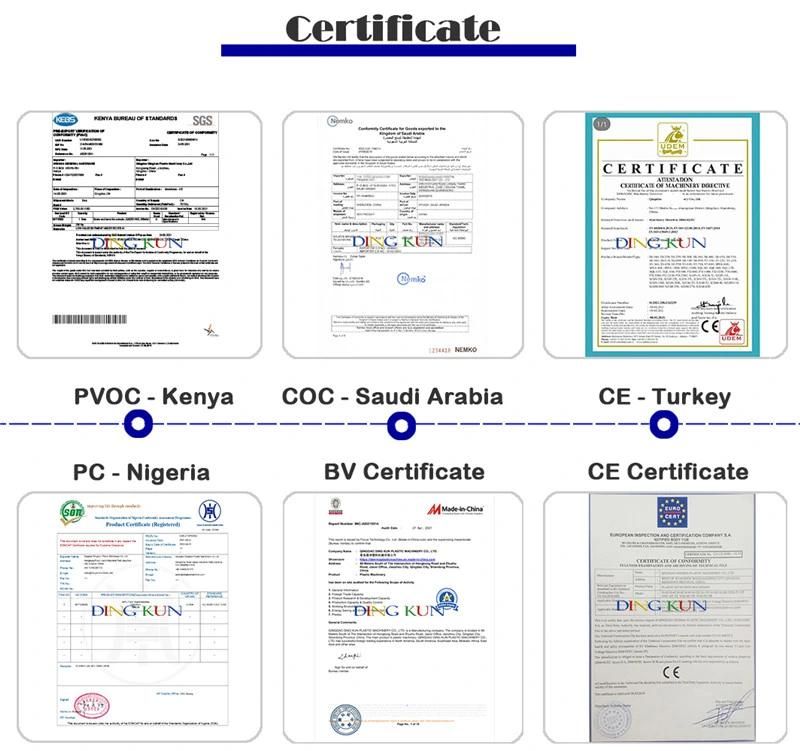

- Certification:CE, ISO9001:2008

- Customized:Customized

- Condition:New

- After-sales Service:Provide Lifelong Service, on Site Repair and Upgra

- Plastic Machine:PVC Pipe Extrusion Machine

- Main Extruder:Sjsz80,156 Double-Screw Extruder

- Pipe Diameter:110 - 200mm Double Pipe

- Main Motor:Siemens Beide

- Output Capacity:180-250kg,Hr

- Total Installed Power:About 50kw

- Overall Dimension:About 24m*2m*2m

- Raw Material:PVC Powder

- Power Supply:380V 3phase 50Hz or as Your Demand

- Operator:1-2 Persons Per Shift

- Inverter:ABB

- Temperature Meter:Omron

- Relay / Switch:Siemens

- Transport Package:Mold: Wooden Package. Outside: Stretch Film

- Specification:CE SGS TUV ISO

- Trademark:DINGKUN

- Origin:Qingdao of Shandong

- HS Code:847209000

- Production Capacity:300-400kg,Hr

Description

Produce process :

PVC powder + additive → mixing → spring feeding → twin screw extruder → mould and calibrator → vacuum forming machine → haul off machine → cutting machine → stacker

Main Composition

Model:SJZ80/156 Capacity: 300-400kgs/h Motor power: 55kW Material of screw & Barrel: 38CrMoAl & Bimetallic

Die Head : Main materials of Body, bin and push: 40Cr, Surface polishing and CR-plating Calibrator: copper or stainless steel, water-ring type Inside flow channel Mirror polished Special chrome plated treatment: 20-30 um Ceramic heaters, high efficient and long life Spider structure for excellent plasticization

Vacuum Tank : Tank materials: 6-8mm 304 S. S.Materials Water temperature and level controlling technology; High pressure and stable water jet. Pressure protection design

Haul off Machine : Haul-off speed range: 0.5-6m/min AC frequency motor with force cooling fan: Hard gear reducer Speed driving and control: ABB inverter

Cutter :Cutting length: Measured by encoder or travelling switch Frame structure: beautiful appearance, safe operation Italian hydraulic system: less leakage Adopts pulse system for dust removal: no dust accumulation

DINGKUN is committed to providing full support for its local and international clients and dealers and will always provide a prompt response to customer enquiries.

1. Provide all the machines for the complete production according to customer's requirements.

2. Provide complete service for factory layout and other information to help customer to build the factory.

3. Provide the raw material to the customer if need.

4. Provide good service for machine installation and training, until the customers can run the machines and make stable production.

5. Provide after-sell service for all the life, except one year quality guarantee,

6. Provide good quality, good price and good service to customer. We are the professional and trustable supplier for turnkey projects. Let us do win-win business together.

*Before-sale:

Introduce products professional

Project engineering

*During manufacturing:

Provide layout and engineering conditions

Inform the schedule of production

Make sure the product designed in accordance with technical document

Test machine before delivery

Provide photos before shipping

*After-sale:

Build customers database. All machines are traceable.

Overseas installation, commissioning and training are available

Speed up service and spare parts supply.

Visit customers and make quality trace periodically