PP PS Pet Sheet Extrusion Machine (usual sheet width & thickness)

Qingdao Leader Machinery Co., Ltd.- Warranty:12 Mounths

- Type:Sheet Extruder

- Plastic Processed:PP

- Product Type:Extrusion Molding Machine

- Feeding Mode:Multiple Feed

- Assembly Structure:Integral Type Extruder

Base Info

- Screw:Single-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Main Electrical Parts:ABB, Omron, Rkc, Schneider, FUJI, Delix etc.

- Customized:Customized

- Application:Housing Waterproof, Architecture Engineering

- Model No:Sjsz80,156

- Board Width:700-2200mm

- Board Thickness:0.5-2mm, 1.5-10mm, 6-20mm, 3-30mm

- Die Head:T-Type, Jc-Times Brand

- Transportation:2X40f Containers

- Extruder Model:High Efficiency Single Screw Extruder 150,33

- Three Roller Calendars:Vertical Type, Alloy Steel Material

- Transport Package:Wooden Pallets and Cases and Films

- Specification:500-600kg,H

- Trademark:Leader Machinery

- Origin:Qingdao of China

- HS Code:8477209000

Description

Basic Info.

Screw Single-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Main Electrical Parts ABB, Omron, Rkc, Schneider, FUJI, Delix etc. Customized Customized Application Housing Waterproof, Architecture Engineering Model No Sjsz80/156 Board Width 700-2200mm Board Thickness 0.5-2mm, 1.5-10mm, 6-20mm, 3-30mm Die Head T-Type, Jc-Times Brand Transportation 2X40f Containers Extruder Model High Efficiency Single Screw Extruder 150/33 Three Roller Calendars Vertical Type, Alloy Steel Material Transport Package Wooden Pallets and Cases and Films Specification 500-600kg/H Trademark Leader Machinery Origin Qingdao of China HS Code 8477209000Product Description

PP PS sheet extrusion machine

This line is specially used for producing PP/PE/PS/ABS single layer or multi-layer sheet or plate, suitable in the fields of packaging, stationery, chemicals, construction, household appliances and so on.

Main technical data:

1. Usual sheet width:

700, 900, 1020, 1200, 1300, 1400, 1500, 1700, 1800, 2100, 2200mm

2. Usual Sheet thickness

: 0.5-2mm, 1.5-10mm, 6-20mm, 3-30mm

3. Extruder: Special screw structure, imported world-known thermocontrollers, electronics, hard gear face reducers to ensure high effective material extrusion capacity.

4. T -type die head:

Suitable compression ratio to ensure uniform flow stability.

5. Three-roller calendar:

According to the material properties, adopting vertical three-roller, oblique three-roller, horizontal three-roller calendar. Internal roller temperature control using a unique flow channel, so that the stability of uniform distribution roller. The independent oil temperature control for three roller to ensure more stable and exact control.

6. Cooling frame: According to product specifications, configurations with different specifications of the stainless steel cooling roller

7. Edge-cutting devices: Trimming can be divided into manual and automatic, three-dimensional configuration tool adjustment device, width adjustable.

8. Cut off machine: Saw cutting or knife cutting, thin type and non-friable type sheet generally usually knife cut, adopted high-quality alloy cutting tools, sharp and durable.

MACHINE PICTURES:

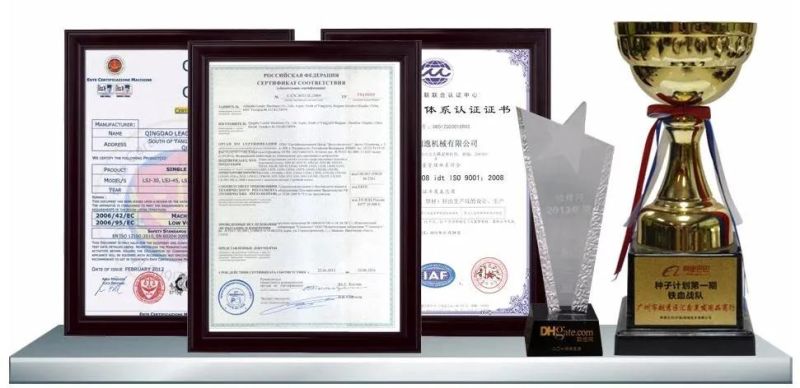

COMPANY CERTIFICATIONS OF:

OTHER PLASTIC SHEET EXTRUSION LINE RECOMMEDATION

1. PC/PP hollow profile sheet/hollow grid sheet extrusion line

Processing material: PC/PP virgin material plus recycle material

Thickness range: 2mm-4mm-6mm-8mm-10mm-12mm

Net sheet width: 1220mm-2100mm

Layer structure: Single layer or multi-layer

Capacity: 200-600kg/h

Application: Ads. Decoration, roofing, packaging, printing, etc.

2. ABS/HIPS sheet extrusion machine:

Processing material: ABS/HIPS virgin pellets plus recycle material

Thickness range: 1-6mm

Net Sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 400-800kg/h

Application: Vacuum forming, thermoforming, refrigerator inner layer, suitcase, etc.

3. ABS/PMMA sheet extrusion machine:

Processing material: ABS/PMMA virgin pellets plus recycle material

Thickness range: 1-8mm

Net sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity: 400-800kg/h

Application: Vacuum forming, bathtub, etc.

4. PP PE foam board/sheet extrusion line

Processing material: PP, PE , Foam additives, master batch

Thickness range:0.8-3-12mm

Net sheet width: 600mm-1260mm-

Layer structure: Single layer or double layers (A/B), three layers (A/B/A, A/B/C)

Capacity: 150-500kg/h

Application: stationery, containers, handbags, heat insulation material, construction, food packing, automobile area, industry application, sports fields etc.

5. PE HDPE sheet extrusion machine:

Processing material: HDPE/LDPE/LLDPE virgin pellets plus recycle material

Thickness range: 1-2.5mm, 3-35mm

Net sheet width: 1200mm-1600mm-1800mm-2500mm-3000mm-40000mm-6000mm-8000mm

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1200kg/h

Application: Packaging, construction, water-proof, water-drainage, Geomembrane film, etc.

6. PC/GPPS/PMMA sheet extrusion machine:

Processing material: PC/GPPS/PMMA virgin pellets plus recycle material

Thickness range: 1-12mm

Net sheet witdh: 600mm-1220mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 400-600kg/h

Application: Ads., decoration, roofing, etc.

7. PP/PS sheet extrusion machine:

Processing material: PP/PS virgin pellets plus recycle material;

Thickness range: 0.15-2mm

Net sheet width: 650mm-720mm-1000mm-1300mm-1500mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1000kg/h

Application: Thermoforming(cup, bowl, etc. ), stationery, printing sheet, packaging, etc.

8. PET sheet extrusion machine:

Processing material: PET virgin pellets(APET or PETG) plus flakes; Or 100% flakes

Thicknes range: 0.2-1.5mm

Net sheet width: 650mm-1500mm(or as per cusotmer's requirement)

Layer structure: Signle layer or multi-layer

Capacity: 150-500kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

9. PVC sheet/edge banding sheet/marble sheet machine:

Processing material: PVC power plus other additive

Thickness range: 0.15-1mm; 1-3mm; 3-12mm

Net sheet width: 650mm-2000mm-3000mm( or as per customer's requirements)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-500kg/h

Application: Thermoforming, stationery, printing, payment card, SIM card, construction, etc.

10. EVA car interior decoration sheet extrusion line

Processing material: EVA and other additives

Thickness range: 1-8mm

Width range: 1000-1800mm

Layer strcuture: single layer

Capacity: 500-800kg/h

Application: automotive sealing strips, sound insulation cushion, sound absorption sheets,

automobile tail box, fenders, car interior and exterior decoration parts etc.

11. PVC+PMMA Glazed roofing tiles/corrugated sheet extrusion machine

Processing material: PVC, PMMA and other additives

Thickness range: 1-8mm

Width range: 720mm, 880mm, 1040mm

Layer structure: A/B, A/B/A, A/B/C

Capacity: 400kg/h

Application: garden-style factory, tourist scenic spots, pavillions, hotels, family building etc.