Sjz80/156 Extruder PVC Powder Pelletizing Machine Plastic Soft Rigid PVC Pelletizing ...

Zhangjiagang City Prowell Technology Co., Ltd.- After-sales Service:1 Year

- Warranty:1 Year

- Raw Material:PVC

- Screw:Double-Screw

- Inverter:Inverter

- Electromagnetic Heater:Electromagnetic Heater

Base Info

- Model NO.:PVC Granulator

- Automation:Automatic

- Computerized:Computerized

- Customized:Customized

- Certification:CE, ISO9001:2008

- Condition:New

- Motor:37kw

- Frequency Brand:ABB

- Transport Package:Wooden Packing

- Specification:4800*2640*2480

- Trademark:Prowell

- Origin:China

- HS Code:8477800000

- Production Capacity:20set,Year

Description

Basic Info.

Model NO. PVC Granulator Automation Automatic Computerized Computerized Customized Customized Certification CE, ISO9001:2008 Condition New Motor 37kw Frequency Brand ABB Transport Package Wooden Packing Specification 4800*2640*2480 Trademark Prowell Origin China HS Code 8477800000 Production Capacity 20set/YearProduct Description

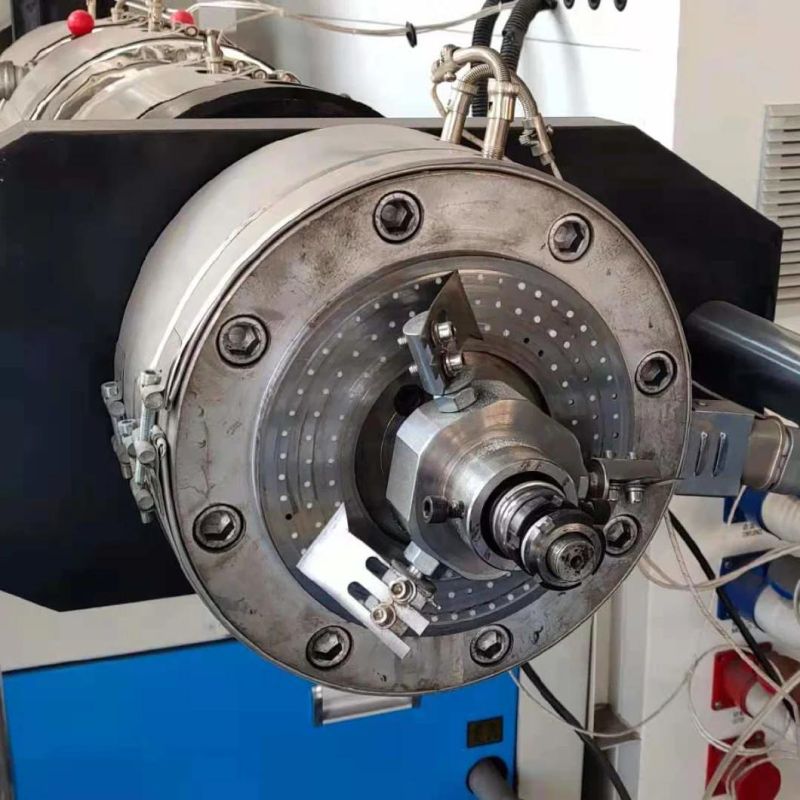

The SJZ80/156 Extruder PVC Powder Pelletizing Machine Plastic soft rigid PVC pelletizing making machine with knife cutting device is used in the field of PVC recycling crushed material and waste material granulation Through the process of melting, extruding, pelletizing and drying, recycled materials, waste materials will become PVC particles Then Granules are widely used in the plastic industry, sheet, pipe, and profile production.

Production Line mainly adopts the method of grinding and hot-cutting to granulate the plastics with relatively cold curing characteristics (such as HDPE, PVC) and filled modified plastics (such as calcium filling) without water so the die surface is eagerly cut and granulated to make the appearance of the material particles smooth, full and beautiful.

Because the system adopts a modular design then users can also choose secondary air conveyors vibrating screens and other configurations according to process requirements to achieve different process requirements.

Brief description of PVC hot-cut granulation unit:

| Model | SJSZ-51 | SJSZ-65 | SJSZ-80 |

| Extruder | SJSZ-51/105 | SJSZ-65/132 | SJSZ-80/156 |

| Power | 45 kw | 70kw | 100 kw |

| Output | 120kg/h | 280kg/h | 350kg/h |

| Granulator | φ3mm-4 | φ3mm | φ3mm |

| Total Length | 12meters | 15meters | 17meters |