Plastic Extruding Machine for Making PP Honeycomb Tube

Creation Glory Machinery Limited- Type:Pipe Extruder

- Plastic Processed:PP, Poe

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Screw:Single-Screw

Base Info

- Model NO.:YJ-PPHT9

- Engagement System:Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Performance:Good

- Quality:High

- Efficiency:High

- Output:High

- Operation:Easy

- Maintenance:Easy

- Precision:High

- Running:Stable

- Color:as Per Standard

- Volt:220V, 380V, 415V, 440V

- Transport Package:Plastic Film, Wooden Pallet

- Specification:CE

- Trademark:Yuanjin

- Origin:Foshan, China

- HS Code:8477209000

- Production Capacity:50sets,Month

Description

Basic Info.

Model NO. YJ-PPHT9 Engagement System Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Performance Good Quality High Efficiency High Output High Operation Easy Maintenance Easy Precision High Running Stable Color as Per Standard Volt 220V, 380V, 415V, 440V Transport Package Plastic Film, Wooden Pallet Specification CE Trademark Yuanjin Origin Foshan, China HS Code 8477209000 Production Capacity 50sets/MonthProduct Description

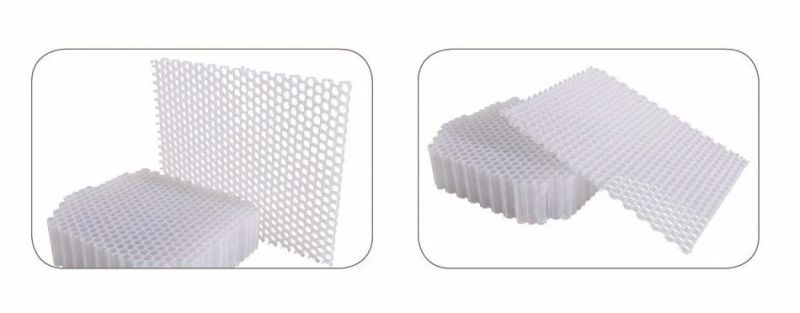

Plastic Extruding Machine For Making PP Honeycomb Tube

Introduction of Plastic Extruding Machine For Making PP Honeycomb Tube

1. This PP honeycomb tube plastic extruding machine is applied for production of PP honeycomb tube, which is super light, environment-friendly, with high strength, widely used in home decoration, architecture etc, because of its features like water-proof, sound-insulation, thermal-insulation, mildew proof, easy constructed.

2. Applied materials: PP, POE etc;

3. Production process flow:

Extrusion----Vacuum cooling calibration----Haul off----Cutting.

Composition of Plastic Extruding Machine For Making PP Honeycomb Tube

| MACHINE PARTS | QUANTITY |

| HONEYCOMB TUBE SINGLE SCREW EXTRUDER MACHINE | 1 SET |

| HONEYCOMB TUBE EXTRUSION MOULD | 1 SET |

| HONEYCOMB TUBE VACUUM CALIBRATION WATER TANK | 1 SET |

| HONEYCOMB TUBE HAUL OFF SYSTEM | 1 SET |

| HONEYCOMB TUBE CUTTING MACHINE | 1 SET |

PP Honeycomb tube:

Why choose CREATION GLORY MACHINERY?

1. Professionality:

Specialized in plastic extrusion production line design and manufacturing for more than 10 years, we are serving lots of big and small companies in China and also over the world, including many listed companies.

2. Technology:

Extrusion technology is critical in plastic product extrusion production, we own leading extrusion technology in producing various plastic products including pipe, profile, filament and strip, tape etc, so as to help our clients set up plastic extrusion whole plant for producing various plastic extrusion products successfully and stably;

3. Quality:

The quality of products is footstone of enterprise's constant development, always endeavoring to do much better, quality comes first, developing & innovative is our responsibilities;

We always care quality of each and every small part of the machines, and keep improving design and structure of whole line, so that our clients could get the production lines in good quality, with excellent performance, stable running and also with long life. Hnesty:

4. Honesty:

Working in plastic extrusion industry for more than 10 years basing on sincerity, we enjoyed good reputation in this industry, and we keep very good relationship with our suppliers, clients and partners all over the world.

FAQ

Q1: What is your guarantee of the machine?

A1: The guarantee period of our machine is 12 months;

Q2: What package do you use for the machine?

A2: Painted the machine with anti-corrosion oil, and then covered with plastic film, and then packed into wooden case or fixed onto wooden pallet as per clients' requirements, or shall be loaded into container in nude packing.

We place and fix the machines well into container and check carefully before closing the container

so as to ensure everything is well for the shipment. We care each and every point so that our clients could receive the machines in good status.

Q3: What is delivery time of the machine?

A3: About 45 days after receipt of advance payment;

Q4: What is your payment terms?

A4: 30% advance payment by T/T upon order, balance 70% by T/T before shipment OR by L/C;

Q5: Which countries do you sell your machines to?

A5: Our plastic extrusion machines were sold to Russia, Ukraine, South Korea, Thailand, Malaysia, Vietnam, India, Bangladesh, Canada, USA etc countries.

Q6: What is your service to overseas clients?

A6: We supply consummate service for overseas clients. We shall send engineers to overseas for machine installation and commissioning and test production guide, and also training to the workers of the buyer. And we are ready to give technical support anytime.