PP PE Multilayer Plastic Thick Board Extruder Machine for Construction Molding

Qingdao Weier Plastic Machinery Co., Ltd.- After-sales Service:Provide

- Warranty:Provide

- Type:Sheet Extruder

- Plastic Processed:PE

- Product Type:Extrusion Molding Machine

- Feeding Mode:One Feed

Base Info

- Model NO.:SJ120,33

- Assembly Structure:Integral Type Extruder

- Screw:Single-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- PE Sheet Production Line Raw Material:PE

- PE Sheet Production Line Power Supply:380V Three Phase

- Center Height:1000mm

- Power:90kw

- Dimentions:40*4*4mm

- Weight:15t

- Sheet Width:2000mm

- Transport Package:According to Customers Needs

- Specification:CE ISO9001 2008

- Trademark:WEIER

- Origin:Qingdao, China

- HS Code:84772090

- Production Capacity:90 Sets Year

Description

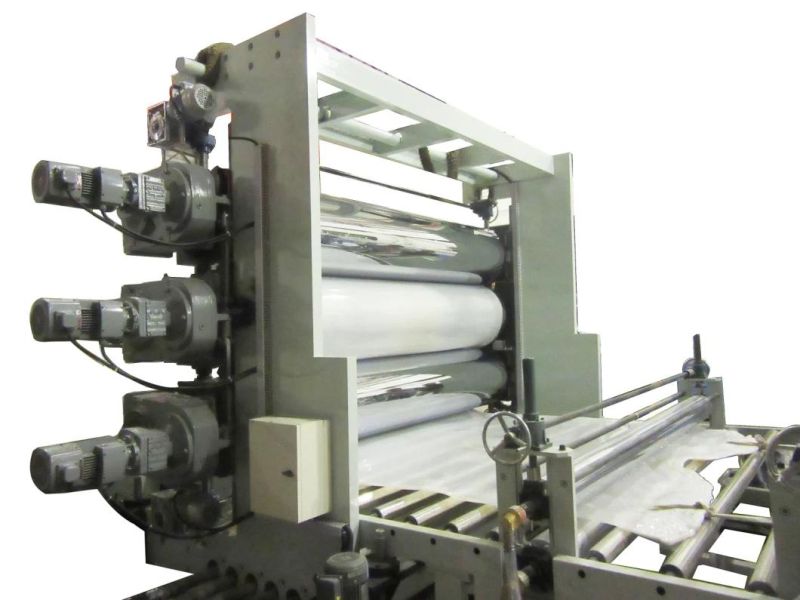

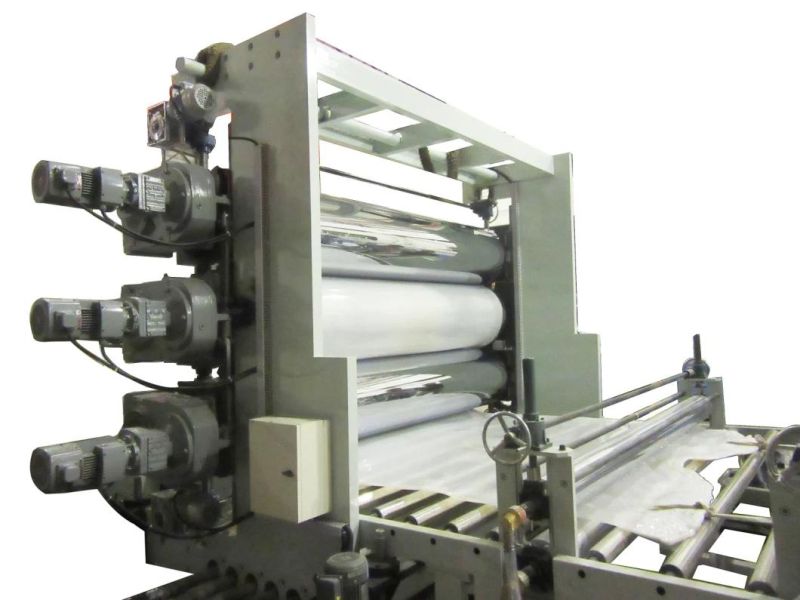

PMMA ASA PP PE Thick Board Extrusion Line

---Features at a glance--- The extrusion line by picture is used to produce thick board with width 2000mm, max. output upto 400kg/hr. The extrusion line equiped extruder SJ120/33, the line outside dimensions :23*4.5*5M

The extrusion line by picture is used to produce thick board with width 2000mm, max. output upto 400kg/hr. The extrusion line equiped extruder SJ120/33, the line outside dimensions :23*4.5*5M

---Product Specifications---

---Product Details--- Single screw extruder

Single screw extruder

Screw adopts special mixing function and high plasticizing capacity design, famous imported world-known thermocontrollers,electronics, hard gear surface gearbox to ensure high effective material extrusion capacity. Mould

Mould

Mould adopts excellent mould special steel 5CrNiMo, suitable compression ratio to ensure uniform flow stability. Using a special double flow design which allows more precise adjustment to sheet thickness. Temperature control of plus or minus 1 ºC can accurately control the plasticizing process and sheet thickness.

3-roller calendar

According to the material properties, adopting vertical three-roller, oblique three-roller, horizontal three-roller calendar.Internal roller temperature control adopts a unique flow channel, so that the stability if uniform distribution roller. The independent oil temperature control for three roller calendar to ensure more stable and exact control.

Cutting machine

Cutting machine

It can be divided into saw cutting or knife cutting. Thin type and non-friable type sheet usually adopt knife cut, adopting high quality alloy cutting tools, sharp and durable. Thick type sheet usually use saw cutting.

---Company Profile---

---Company information---

Qingdao Weier Plastic Machinery Co.,Ltd ,the professional manufacturer of plastic machines,which is engaged in macromolecule science,is the director member of WPCC (plastic & wood production council of Chinese plastic community). We cooperated with many domestic universities to develop special plastic machines to meet domestic and foreign customer's requirement .

Now we become the test and industrialization centre of plastic engineering technology research institute Qingdao Science and Technology University. At the same time we bring in and absorb advanced processing engineering of foreign plastic machines.To realize chain service of technics and machines.

We have more than 30 machine lines running in China market; Welcome to visit us, and also can show the machine line running in client's factory.

---Why choose Weier---

---FAQ---

A:1)30% of total amount paid by TT as advance, then the seller start production

2)after the machine is finished ,buyer come to test the machine in seller's factory ,

and then pay the 70% balance by TT or irrevocable L/C at sight . Then seller ship the machine.

Q2.How long is the delivery time?

A: For standard machines, it would be 30 days; For non-standard machines and customized machines according

to client s specific requirements, it would be 45 days.

Q3.Do you arrange shipment for the machines?

A:Yes,for FOB or CIF price, we will arrange shipment for you.

Q4.How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List,

Commercial Invoice, B/L, and other certificates as required by clients.

Q5.What's your after-sales service ?

(1)The supplier provides service manual and maintenance instruction of main electric appliances, limb, usage manual of equipment. We also supply water, electricity, gas of equipment and installation drawing. (2)The supplier is responsible for installation, debugging and training, but the air tickets, insurance, eating, housing and every day 100 USD for each engineer will be born by the buyers. We will realize guarantee of repair; replacement and refund of substandard products within one year after the machine leaves factory. And half a year for electric parts. Fittings of the machine will be supplied at preferential price after one year.

Q6.What's your warranty?

We will realize guarantee of repair; replacement and refund of substandard products within one year after the machine arrived in customer's factory (except destroyed by buyers' wrong operation). We guarantee the material of screw & barrel (guarantee without normal abrasion). And half a year for electric parts. Fittings of the machine will supply at preferential price after one year.

Contact Person:Yuriy Yu 0086 15908964630

---Features at a glance---

The extrusion line by picture is used to produce thick board with width 2000mm, max. output upto 400kg/hr. The extrusion line equiped extruder SJ120/33, the line outside dimensions :23*4.5*5M

The extrusion line by picture is used to produce thick board with width 2000mm, max. output upto 400kg/hr. The extrusion line equiped extruder SJ120/33, the line outside dimensions :23*4.5*5M

---Product Specifications---

---Product Details---

Single screw extruder

Single screw extruderScrew adopts special mixing function and high plasticizing capacity design, famous imported world-known thermocontrollers,electronics, hard gear surface gearbox to ensure high effective material extrusion capacity.

Mould

MouldMould adopts excellent mould special steel 5CrNiMo, suitable compression ratio to ensure uniform flow stability. Using a special double flow design which allows more precise adjustment to sheet thickness. Temperature control of plus or minus 1 ºC can accurately control the plasticizing process and sheet thickness.

3-roller calendar

According to the material properties, adopting vertical three-roller, oblique three-roller, horizontal three-roller calendar.Internal roller temperature control adopts a unique flow channel, so that the stability if uniform distribution roller. The independent oil temperature control for three roller calendar to ensure more stable and exact control.

Cutting machine

Cutting machineIt can be divided into saw cutting or knife cutting. Thin type and non-friable type sheet usually adopt knife cut, adopting high quality alloy cutting tools, sharp and durable. Thick type sheet usually use saw cutting.

---Company Profile---

---Company information---

Qingdao Weier Plastic Machinery Co.,Ltd ,the professional manufacturer of plastic machines,which is engaged in macromolecule science,is the director member of WPCC (plastic & wood production council of Chinese plastic community). We cooperated with many domestic universities to develop special plastic machines to meet domestic and foreign customer's requirement .

Now we become the test and industrialization centre of plastic engineering technology research institute Qingdao Science and Technology University. At the same time we bring in and absorb advanced processing engineering of foreign plastic machines.To realize chain service of technics and machines.

We have more than 30 machine lines running in China market; Welcome to visit us, and also can show the machine line running in client's factory.

---Why choose Weier---

- We are engaged in macromolecule science, is the director member of WPC (plastic & wood production council of Chinese plastic community)

2.We cooperated with many domestic universities to develop special plastic machines to meet domestic and foreign customer's requirement.

3.We become the test and industrialization centre of plastic engineering technology research institute of Qingdao Science and Technology University.

4.we bring in and absorb advanced processing engineering of foreign plastic machines to realize chain service of technics and machines.

5.We have experiences in this field since 1980s

6.We have our production bases for WPC and plastic product in China with large scales, which shows our machine's production power

7.We have strong technical teams and cooperate with China scientific institution to develop, improve and test our machine, to ensure what customers get are the most reliable machines from China.

8.We select the most reliable mechanical and electrical parts for our machine with all famous reliable brands, with European CE certificated.

9.We put our heart into every business with aim of long term cooperation.

10.We have perfect service system-- Our president is devoting himself to pre-sale, on-sale and after-sale service. WEIER JUST DO WIN-WIN BUSINESS!!!

---FAQ---

A:1)30% of total amount paid by TT as advance, then the seller start production

2)after the machine is finished ,buyer come to test the machine in seller's factory ,

and then pay the 70% balance by TT or irrevocable L/C at sight . Then seller ship the machine.

Q2.How long is the delivery time?

A: For standard machines, it would be 30 days; For non-standard machines and customized machines according

to client s specific requirements, it would be 45 days.

Q3.Do you arrange shipment for the machines?

A:Yes,for FOB or CIF price, we will arrange shipment for you.

Q4.How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List,

Commercial Invoice, B/L, and other certificates as required by clients.

Q5.What's your after-sales service ?

(1)The supplier provides service manual and maintenance instruction of main electric appliances, limb, usage manual of equipment. We also supply water, electricity, gas of equipment and installation drawing. (2)The supplier is responsible for installation, debugging and training, but the air tickets, insurance, eating, housing and every day 100 USD for each engineer will be born by the buyers. We will realize guarantee of repair; replacement and refund of substandard products within one year after the machine leaves factory. And half a year for electric parts. Fittings of the machine will be supplied at preferential price after one year.

Q6.What's your warranty?

We will realize guarantee of repair; replacement and refund of substandard products within one year after the machine arrived in customer's factory (except destroyed by buyers' wrong operation). We guarantee the material of screw & barrel (guarantee without normal abrasion). And half a year for electric parts. Fittings of the machine will supply at preferential price after one year.

Contact Person:Yuriy Yu 0086 15908964630