Extruder Auxiliary Machine Side Feeder Adding Power and Fiber

Joiner Machinery Co., Ltd.- After-sales Service:24 Hours

- Warranty:6 Months

- Standard:DIN, GB, ANSI

- Technics:CNC Machining,Assembling

- Feature:New Machine

- Material:as Request

Base Info

- Model NO.:Model 63

- Screw Material:38crmoala

- Barrel Material:38crmoala

- Screw Hardness:Hv950 -1100

- Nitriding Thickness:0.5 -0.7mm

- Shaft Material:H13

- Shaft Hardness:HRC 38-42

- Hopper:316L

- Material Feature:Corrosion Resistance

- Motor Brand:Sew

- Transport Package:Wooden Box

- Specification:About 1500*650*1230(mm)

- Trademark:Joiner

- Origin:China

- HS Code:8477900000

- Production Capacity:2000 Pieces,Year

Description

2. Machine parts:

3. Advantages of Joiner Extrusion Side Feeder

1). Independently develop and produce gearboxes.

a. All gearboxes are machined by gear grinding, the accuracy is up to six grades, and carburizing and hardening the tooth surface, thus ensuring that the noise of gearboxes is very low.

b. Gear casting is made of resin sand and machining center to ensure high precision.

c. The gearbox's bearing is imported from Germany.

d. The gearbox has unique design, long life and low noise.

e. The gearbox and screw element are connected by spline sleeve, which is very convenient to disassemble

2). Barrel is made of wear resistant alloy steel and cooled by water channel.

3). Screw adopts modular screw, and the screw assembly can be adjusted according to different feeding materials to meet different feeding requirements.

4. Side feeders are used for the following reasons:

--reduction of wear costs in the melting section of the main screw and barrels

--More gentle processing of fillers

--Increase in throughput

--Increase in quality through the enough fixing

--Lower the cost

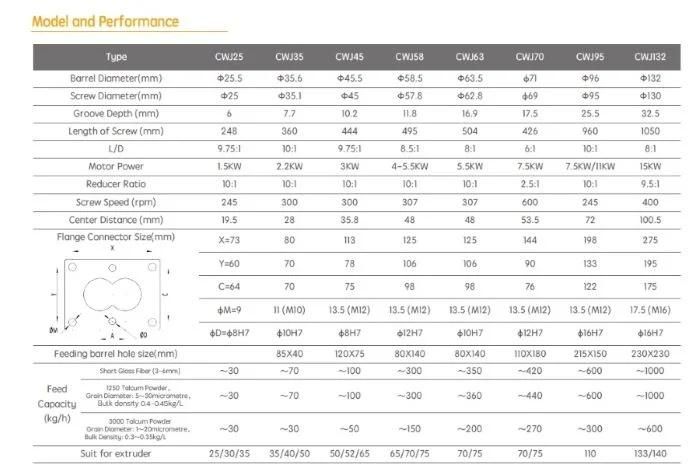

5. All models we produce

6. Raw material guarantee

The company has been cooperating with domestic and foreign first-line brand material suppliers for a long time, and strictly inspects the factory (elemental analysis, metallographic analysis, ultrasonic flaw detection, etc.) to ensure 100% qualified.

7. Professional monitoring equipment guarantee

We have three coordinate detector, two dimensional image measuring instrument, metallographic analyzer, ultrasonic flaw detector, element analyzer and other more than 10 kinds of advanced detection equipment, which is the strong guarantee of quality stability! 8. Why choose us?

8. Why choose us?

(1) Total solution of highly wear-resistance and corrosion-resistance problems;

(2) Expert of engineering design and consulting,

(3) Advanced manufacturing capabilities and technology,

(4) Lean production management

(5) Top quality products with high cost performance

9.Production Equipment

We also have advantages in production equipment and inspection equipment.

Joiner has over130 advanced equipment such as CNC thread grinder, CNC thread milling, CNC kneading block grinder, CNC forming milling, 4-axis machining center, automatic deep hole grinder, CNC lathe, CNC surface grinder, CNC external grinding, CNC band saw, laser marking machine, vacuum quenching furnace and vacuum tempering furnace. After the raw materials enter the market, all the processing procedures are in-house.

10. Quality

The quality of JOINER products is subject to internal quality control standards as well as to the quality management system ISO 9001:2000. By controls of the staff, all manufacturing steps are continuously checked. Before products leave the plant, they are subject to final quality control procedures. This is how we can guarantee quality at the highest level.

11. Products photos:

12. FRQ

1. Q: Are you a factory or trading company?

----A: A factory

2. Q: Where is your factory located? How can I visit there?

-----A: Our factory is located in Chengdu, Sichuan Province, China,

1) You can fly to Chengdu Airport directly. We will pick you up when you arrive in the airport;

All our clients, from domestic or abroad, are warmly welcome to visit us!

3.Q: What makes you different with others?

----A: 1) Our Excellent Service

For a quick, no hassle quote just send email to us

We promise to reply with a price within 24 hours - sometimes even within the hour.

If you need an advice, just call our export office at +86 19150954315, we will answer your questions immediately.

2) Our quick manufacturing time

For Normal orders, we will promise to produce within 30 working days.

As a manufacturer, we can ensure the delivery time according to the formal contract.

4.Q: How about the delivery time?

----A: This depends on the product. Typically standard products are delivered within 60 days.

5.Q: May I know the status of my order?

--A: Yes.We will send you information and photos at different production stage. You will get the latest information in time.