China Manufacturer 500kg/Hr PP PE LDPE LLDPE HDPE Polyethylene Film Recycling Pelletizing ...

ZHANGJIAGANG RETECH MACHINERY CO., LTD.- After-sales Service:Yes

- Warranty:1 Year

- Material Processed:Film

- Plastic Type:PE

- Screw:Single-Screw

- Automation:Automation

Base Info

- Model NO.:RCSJ RCDJ

- Computerized:Computerized

- Certification:ISO9001:2008, CE

- Feeding Way:Belt Conveyor with Metal Detector

- Cutter:Compactor

- Extruder:Degassing Screw

- Pelletizing:Die Face Cutting

- Transport Package:by Sea

- Specification:TSSJ100~200 THSJ65~220 TCSJ85~180 TCDJ85~180

- Trademark:RETECH

- Origin:China

- HS Code:8477201000

- Production Capacity:100 Sets Per Year

Description

Detailed Photos

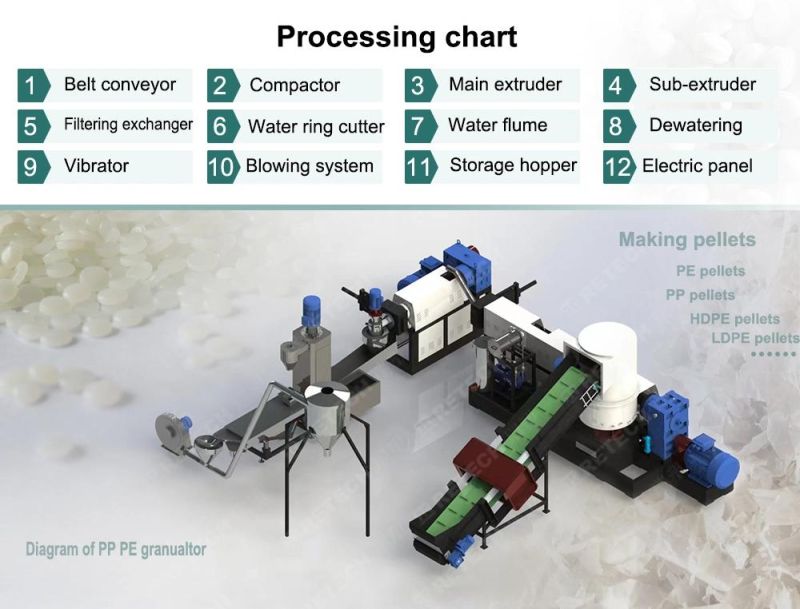

1.One Step, All-in-One direct film recycling machine:

The RCSJ plastic recycling machine combines cutting, extrusion and pelletizing into one compact and efficient recycling line. The cutter compactor of the recycling machine prepares (pre-conditions) the material into an ideal condition for the extrusion process and feed the material directly into the extruder with a centrifugal force. Comparing to the conventional recycling machines, this integrated system does not require a separate crusher, andtherefore, eliminates the problem of inconsistent feeding (over-feeding or insufficient feeding).

2.Easy material feeding without the need for pre-cutting:

The waste material enters the machine from the belt conveyor (for film scraps and rigid plastic regrind) and the nip roll feeder (for complete film rolls) at the same time. An extra silo tank can also be added to store and feed pre-washed film flakes. The feeding is controlled automatically based on how full the cutter compactor is. The cutter compactor then cuts, dries and compacts the material into a semi-molten condition (just below the agglomeration point), which is optimal for the extrusion process that follows. The cutter compactor then feeds the material directly and consistently into the extruder screw

3.Higher output capacity

The integration of the cutter compactor and extruder ensures extremely fast and stable feeding, the tangentially connected extruder is continuously filled with pre-compacted material. This results in a much higher production output comparing to other types of recycling systems on the market

4.Higher pellets quality

The stable material feeding together with the hot die face pelletizer produce round-shaped, uniformed size pellets that are higher in value and optimal for reproduction (extrusion processes).