WPC Foam Board Machine / Plastic Machinery / Extrusion Machine

QINGDAO DING KUN PLASTIC MACHINERY CO., LTD.- Warranty:1 Year

- Type:WPC PVC Foam Board Machine

Base Info

- Model NO.:SJSZ80,156

- Plastic Processed:PVC

- Product Type:WPC PVC Foam Board Machine

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Screw:Twin-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Plastic Machine:High Quality PVC Crust Foam Plate Machinery

- Width of Foam Board:1.22m, 1.56m, 2.05m

- Length of Foam Board:1.22m, 2.44m, 3.05m

- Thickness of Foam Board:5-35 mm

- Hourly Capacity:300-400kg,H

- Motor:Siemens

- Frequency Inverter:ABB

- Contactor:Schneider

- Relay:Schneider

- Temperature Controller:Omron

- Density:0.3 - 0.9g,cm3

- Size:1220*2440mm, 915*1830mm, 1560*3050mm

- Application:Printing, Advertising, Bathroom

- Transport Package:Stretch Film and Wooden Box

- Specification:CE

- Trademark:DINGKUN

- Origin:Jiaozhou, Shandong Province

- HS Code:8477209000

- Production Capacity:15sets,Month

Description

Work flow

PVC powder +additive → mixer →SJSZ series extruder →Coat-hanger type mould →Vacuum calibration cooling platform →cooling rollers and edge-cutting device →Haul off →stacker

Technical information

Description

Parameter

Feed material

PVC+ assistant materials(also can add wood powder)

Product size

1220*2440*5-20mm

Production line speed

0.8-1.5m/min

Max. output

350-500kg/h

Outline size

25×2.5×3 L×W×H(m),unsaturated

Weight

16T

Total power

255kw

Actual energy consumption power

210kw

Main composition

No.

Auxiliary Machines for your choice

No.

Application

Packaging & Shipping

Company Profile

Company Profile

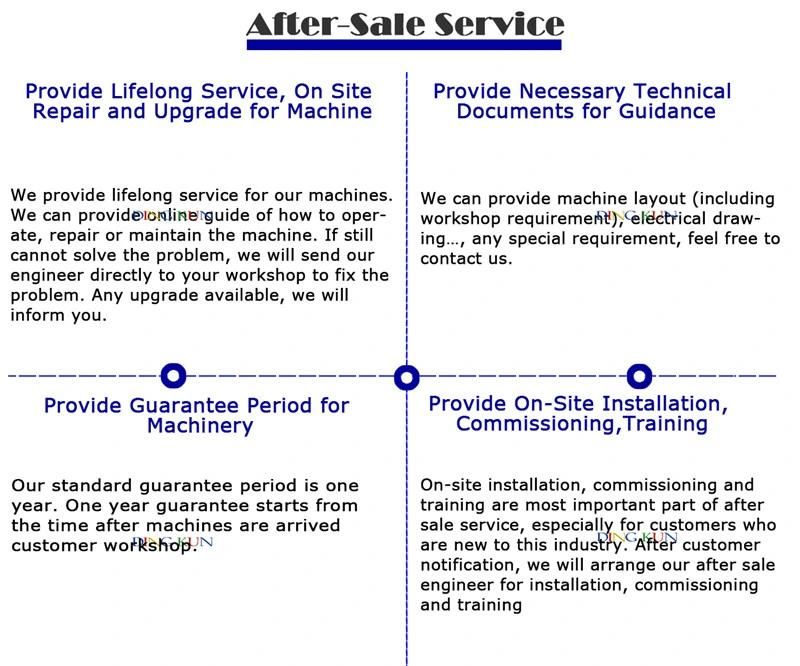

1.We will provide the Feasibility Analysis Report for the wood-plastic project.

2.We will provide the model selection and technical parameter for wood-plastic machinery.

3.We will provide the design for the plant and electric power accounting for the facilities.

4.We will provide the design for wood-plastic formula according to the product requirements.

5.We will provide the technology of wood-plastic product surface treatment

6.We will provide technique training for operator.

7.We will provide solution for the practical problem during the production.

8.We will install and test the machine for free.

9.We will provide turnkey project to customers.

1. Quality Control Management

Q: Is there quality control on all production lines?

A: Yes, all production lines have adequate quality control

Q: Do the QA/QC inspectors work independently from the production line?

A: Yes

Q:How many QA/QC inspectors in total?

A: 4

Q: Number. of Employees in Each Production Line

A: Supervisor 1 ; No. of Operators 29 ;No. of In-line QC/QA 2

2.Supplier Management

Q:Does the company have a supplier assessment procedure?

A:Yes

Q:Does the company have an updated list of approved suppliers?

A:Yes

Q:Does the company establish and implement a standard procedure for purchasing contract review and approval?

A:Yes, with written standard procedures

Q:Does the company keep its supplier assessment reports?

A:Yes, with written standard procedures

Q:Does the company keep its supplier assessment reports?

A:Yes, assessment reports are available for the last 1-3 years

Q:Are the company's purchasing documents sufficient to ensure product safety control and their customers' requirements?

A:Yes, the purchasing document includes all the information required

Q:Is there a procedure to conduct random product inspections after final packaging?

A:Yes, with clear standard and written inspection records

Now we have machines in stock,sincerely invite you to vist our factory! Also you can contact me for machine's running video.