PP Box Strapping Machine and PP Packing Belt Production Line

Sichuan Union Technology Co., Ltd.- Type:Sheet Extruder

- Plastic Processed:PP

- Product Type:PP Strap Extruder

- Feeding Mode:One Feed

- Assembly Structure:Separate Type Extruder

- Screw:Single-Screw

Base Info

- Model NO.:YZJLQD2-3

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Don′t Exhaust

- Automation:Automatic

- Computerized:Computerized

- Voltage:380V 50Hz 3phase(Customized)

- Extrusion Capacity:90kg,H

- Certification:Ce ISO9001

- Line Speed:260m,Min

- PP Belt Width(mm):8-15.5mm

- Deviation of Width (mm):0.4mm

- PP Strap Band Thickness:0.5-1.0mm

- Deviation of Thickness (mm):0.04mm

- Usage:Strap, Packing

- Service:Free Installing and Training

- Transport Package:Ply Wood

- Specification:32m*1.2m*1.2m

- Trademark:YZJ

- Origin:China

- HS Code:8477800000

- Production Capacity:2sets,Month

Description

Basic Info.

Model NO. YZJLQD2-3 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Voltage 380V 50Hz 3phase(Customized) Extrusion Capacity 90kg/H Certification Ce ISO9001 Line Speed 260m/Min PP Belt Width(mm) 8-15.5mm Deviation of Width (mm) 0.4mm PP Strap Band Thickness 0.5-1.0mm Deviation of Thickness (mm) 0.04mm Usage Strap, Packing Service Free Installing and Training Transport Package Ply Wood Specification 32m*1.2m*1.2m Trademark YZJ Origin China HS Code 8477800000 Production Capacity 2sets/MonthProduct Description

Advantages of PP strapping band extrusion machine:

1. Apply to raw materials and recycled materials. Can produce both environmental protection advanced strap and recycled strap

2. The products with high tensile strength, no split, no crack, high market recognition

3. Good shape, even size, achieve automatic packing level.

4. Automatic constant temperature control device

5. Advanced technology, make the product cost is lower more than 10% than the same industry

6. Low noise, less consumption, high efficiency, long service life

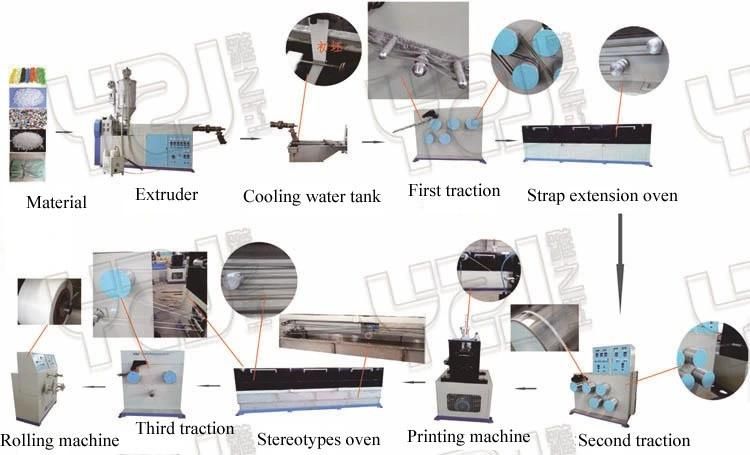

Technical Process of PP strapping band extrusion machine:

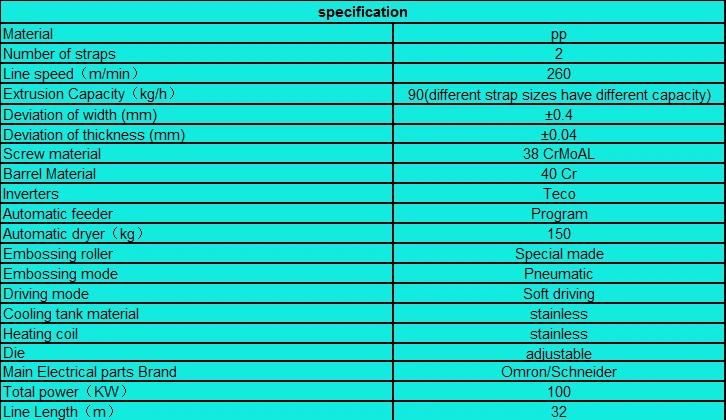

Specification of PP strapping band extrusion machine:

Main Parts of PP strapping band extrusion machine:

Final Product of PP strapping band extrusion machine:

Packing & Delivery:

Contact me:

Advantages:

1. Bengin to produce plastic strapping band and plastic strapping band extruder machine since 1995.

2.Good quality with good price

3.Free Installing and Training