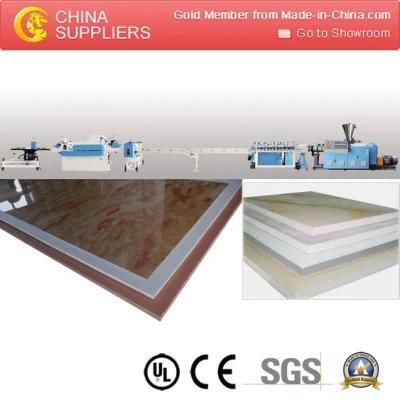

Aluminum Composite Sheet Manufacturing Line

GPM Machinery (Shanghai) Co., Ltd.- Product Type:Aluminum Composite Panel

- Board Layers:Multilayer

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008, UL

Base Info

- Model NO.:GSZ

- Customized:Customized

- Condition:New

- Product Name:Aluminum Composite Sheet Manufacturing Line

- Processing Type:Sheeet Extrusion

- Raw Material:PE

- Usage:Construction, Outdoor Decoration, Sheet

- Motor:Simens

- Inverter:ABB Brand

- Contactor:France Schneider Contactors

- Temperature Control:Japan Omron

- Output:500-600kg,H

- Motor Power:110-132kw

- Transport Package:PE Film Winding Wrapping

- Specification:0.15-1.5mm

- Trademark:GPM

- Origin:Shanghai

- HS Code:8477209000

- Production Capacity:500 Sets,Year

Description

Basic Info.

Model NO. GSZ Customized Customized Condition New Product Name Aluminum Composite Sheet Manufacturing Line Processing Type Sheeet Extrusion Raw Material PE Usage Construction, Outdoor Decoration, Sheet Motor Simens Inverter ABB Brand Contactor France Schneider Contactors Temperature Control Japan Omron Output 500-600kg/H Motor Power 110-132kw Transport Package PE Film Winding Wrapping Specification 0.15-1.5mm Trademark GPM Origin Shanghai HS Code 8477209000 Production Capacity 500 Sets/YearProduct Description

Dimensional TolerancesDue to manufacturing, a displacement of the cover sheets sidewise at the panel edges up to 2 mm is possible.

Thickness: ± 0,2 mm

(mill-finish | stove lacquered | anodized)

Width: - 0 / + 4 mm

Lengths: 1000 - 4000 mm; - 0 / + 6 mm

Lengths: 4001- 6800 mm; - 0 / + 10 mm

composite panels have contact lines (about 25 mm width) on their short sides. For panel lengths of more than 3500 mm, the composite panels have contact lines (about 2 - 3 mm width) on their long sides. Maximum panel length 6500 mm. Please take this into consideration when dimensioning the panels.

composite panel consisting of two aluminium cover sheets and a mineral-filled core. The superb properties of this material boost one's inspiration and offer architecture a whole new range of solutions - whether your project is a private home, a public building, a corporate headquarter and offices, or a trading or industrial complex - or if your organisation wants to create a new image-building Corporate Design - whether for petrol stations, car showrooms, banks or supermarkets.

Advantages

Low weight, high rigidity,perfect flatness, Low cost for substructures and fasteners, Smooth handling on the site

Large variety of colours , Unlimited planning and design, Weatherproof , Supplied ready to install, Vibration-damping , No additional sound-damping needed, Can easily be folded and bent , Simple processing using conventional tools, Large panel sizes, fast installation,pre-fabricated panels , Short construction times,adherence to schedules, low cost.

For choosing the proper machine and saving your time, please read these bellow guides carefully

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the width and thickness of sheet(mm)?

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.

if you are interested in this machine ,please contact me:

mob : +86 13915723896 ( or +86 13817556740 )

Jeremy He