Face Cutting WPC PVC Pelletizing Line

Zhangjiagang Chenxing Machinery Co., Ltd.- Raw Material:PVC

- Screw:Double-Screw

- Inverter:Inverter

- Electromagnetic Heater:Electromagnetic Heater

- Automation:Automatic

- Computerized:Computerized

Base Info

- Customized:Customized

- Certification:CE, ISO9001:2008

- Condition:New

- Cutting Method:Hot Cutting

- Extruder:Conical Twin Screw Extruder

- Screw and Barrel:38crmoaia

- Heater:Aluminum Casting

- Gearbox:Deling Brand

- Cutting Blades:2 PCS

- Air Silo:Stainless Steel Making

- Temperature Controller:Omron

- Contactor:Delixi

- Motor Brand:Xi′an Xima

- Transport Package:Sea Worth Package

- Specification:HC-65

- Trademark:chenxing

- Origin:Jiangsu, China

- HS Code:8477800000

- Production Capacity:500sets,Year

Description

Basic Info.

Customized Customized Certification CE, ISO9001:2008 Condition New Cutting Method Hot Cutting Extruder Conical Twin Screw Extruder Screw and Barrel 38crmoaia Heater Aluminum Casting Gearbox Deling Brand Cutting Blades 2 PCS Air Silo Stainless Steel Making Temperature Controller Omron Contactor Delixi Motor Brand Xi′an Xima Transport Package Sea Worth Package Specification HC-65 Trademark chenxing Origin Jiangsu, China HS Code 8477800000 Production Capacity 500sets/YearProduct Description

Description:

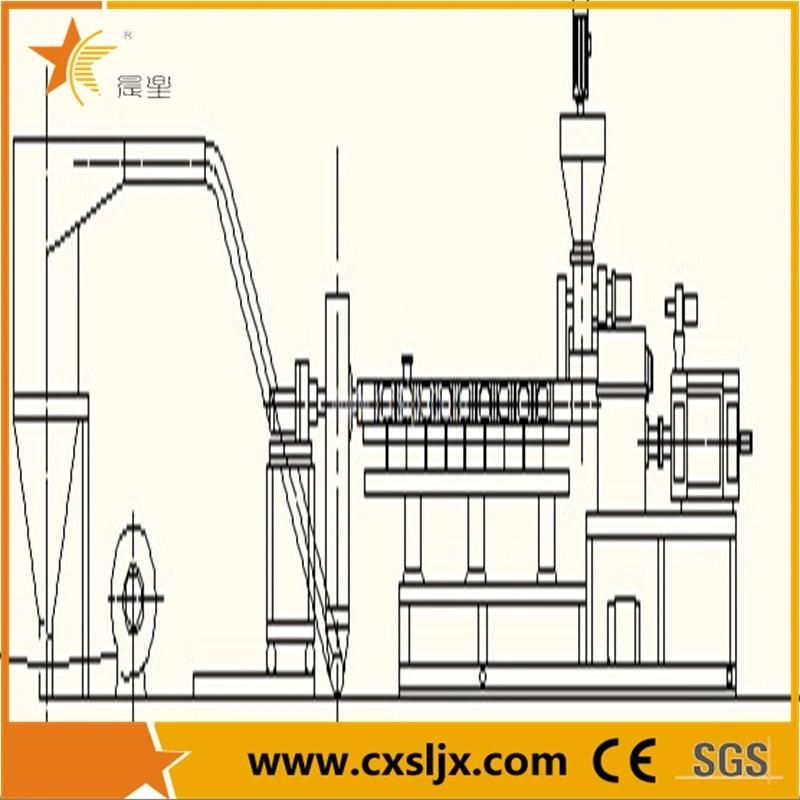

1. This pelletizing machine is composed by SJSZ series conical twin-screw extruder and correspondingly pelletizing auxiliary equipement.

2. Application :It is suitable for pelletiazing PVC,WPC material.

3. Advantages : The pellets produced by this line are even ,solid,elegance.

4. The pelletizaing auxiliary equipement includes die face cutter,air transferring unit,vibration separating and cooling unit,with features of high automation auxiliary equipment includes die face cutter,air transferring unit,vibration separating and cooling unit with features of high automation and high production efficiency

5. Our production has exported to many countriesof all over the world and acclaimed by clients.

6. Process Flow of pvc pelletizing machine:

Mixer→Spiral loader→conical twin-screw extruder→Extrusion mould→Hot-cutting pelletizer→Air cooling conveyor→Packing

7. Features of PVC pelletizing machine:

-speed regulator by frequency inverter, stepless speed adjusting, power saving

-conical twin screw extruder suitable for various PVC granule formula,recipe

-all parts touching final PVC granule are made of stainless steel, rusty proof, no pollution

8. Main technical parameters:

Model | Screw size(mm) | Pellet size(mm) | Power of main | Output(kg/h) |

SJZ55 | 55/110 | Φ3-Φ4 | 22 | 100-120 |

SJZ65 | 65/132 | Φ3-Φ4 | 37 | 220-260 |

SJZ80 | 80/156 | Φ3-Φ4 | 55 | 320-450 |

SJZ92 | 92/188 | Φ3-Φ4 | 110 | 650-800 |