WPC Profile Wood Plastic Production Line

GPM Machinery (Shanghai) Co., Ltd.- Product Type:PVC Profile

- Screw:Single-Screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Customized:Customized

Base Info

- Model NO.:SJZ

- Product Name:Wood Plastic Production Line

- Other Name:Wood Plastic Extrusion Line

- Raw Material:PVC,PP,PE

- Processing Type:Profile Extrusion

- Using:Decoration Board

- Voltage:380V50Hz-3 Phase

- Motor:Simens

- Inverter:ABB Brand

- Contactor:France Schneider Contactors

- Temperature Control:Japan Omron

- Transport Package:PE Film Packaging

- Specification:SJZ

- Trademark:GPM

- Origin:Shanghai

- HS Code:8477209000

- Production Capacity:500set,Year

Description

SPECIFICATIONS FOR PVC/PE/PP WPC PROFILE EXTRUSION LINEModel GSZ65/132 G65 GSZ80/162 G85 GSZ91/188 Driving power 37 37 75 90 110 Max.output(kg/h) 180 300 300 700 500 Weight(T/Day) 3T 5T 6T 12T 11T

4. GSZ65/132 conical twin screw extruder

Max. designed output: 50 ~ 160 kg/h

PP+WOOD special designed for screw with rotation speed of 1 ~ 34.7 r/min

Screw material: 38CrMoAlA, nitrogen treatment, with the thickness: 0.5~0.7mm, hardnessHRC56-60.

Screw core temperature controlling: cooling by circulation heat conduction oil.

Barrel material: 38CrMoAlA, nitrogen treatment, with the thickness: 0.6~0.7mm, hardness HRC62-65

Heating unit: cast aluminium heater + stainless steel covering + cooling fan

Cooling unit: Fan with medium of air, supply precise temperature controlling

Heating zone quantity: 4 with total power 21kw Temperature range: 50~300ºC

Blower fan power: 0.55kw/set (3 set)

For choosing the proper machine and saving your time, please read these bellow guides carefully

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the width and thickness of sheet(mm)?

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.

if you are interested in this machine ,please contact me:

mob : +86 13915723896 ( or +86 13817556740 )

Jeremy He

| NO. | Name | Qty. | Power (KW) | Length (m) | Weight (T) |

| 1 | GSZ65/132 conical twin screw extruder | 1set | 66 | 4 | |

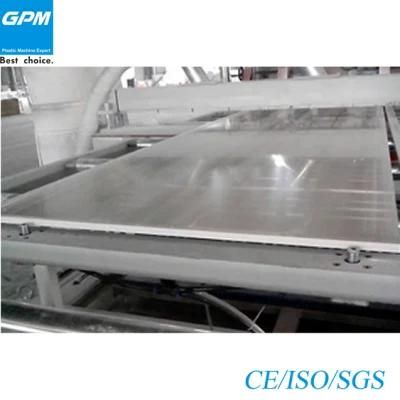

| 2 | XDX240 vacuum calibration table | 1set | 30 | ||

| 3 | XQY240 haul-off unit | 1set | 3 | ||

| 4 | XQG240 cutter | 1set | 2.5 | ||

| 5 | XFL240 stacker | 1set |

4. GSZ65/132 conical twin screw extruder

Max. designed output: 50 ~ 160 kg/h

PP+WOOD special designed for screw with rotation speed of 1 ~ 34.7 r/min

Screw material: 38CrMoAlA, nitrogen treatment, with the thickness: 0.5~0.7mm, hardnessHRC56-60.

Screw core temperature controlling: cooling by circulation heat conduction oil.

Barrel material: 38CrMoAlA, nitrogen treatment, with the thickness: 0.6~0.7mm, hardness HRC62-65

Heating unit: cast aluminium heater + stainless steel covering + cooling fan

Cooling unit: Fan with medium of air, supply precise temperature controlling

Heating zone quantity: 4 with total power 21kw Temperature range: 50~300ºC

Blower fan power: 0.55kw/set (3 set)

For choosing the proper machine and saving your time, please read these bellow guides carefully

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the width and thickness of sheet(mm)?

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.

if you are interested in this machine ,please contact me:

mob : +86 13915723896 ( or +86 13817556740 )

Jeremy He