130ton Medical Injection Molding Machine for Disposable Sterile Burette Infusion Set IV ...

Ningbo Zhen Yue Machinery Co.,Ltd.- Type:Preform Injection

- Structure:Horizontal

- Plastic Type:Thermoplastic

- Plasticizing Way:Screw Type

- Clamping Way:Hydraulic

- Automation:Automatic

Base Info

- Model NO.:ZX-130

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Motor Type:Servo Motor

- Injection Weight:187-293G

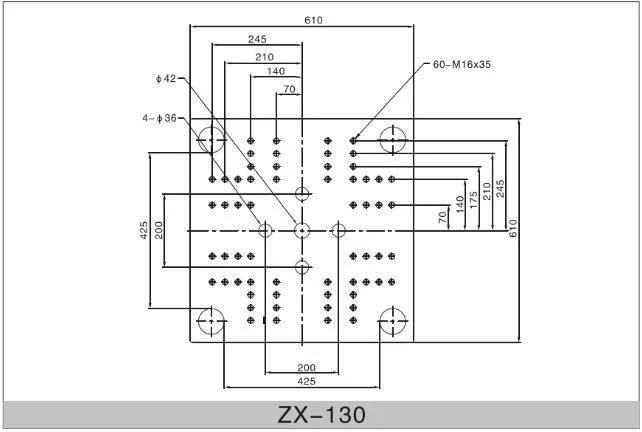

- Space Between Tie Bars:425 X 425mm

- Product 1:Infusion Set Injection Molding Machine

- Product 2:Disposable Infusion Set Injection Moulding Machine

- Product 3:Medical Infusion Set Injection Molding Machine

- Feature 1:High Quality, Advanced Performance, Stable Operate

- Feature 2:Low Cost, Competitive Price

- Feature 3:Professional and Honesty Working Service

- Transport Package:Plastic Film Cover, Wood Pad, Wrapped Film

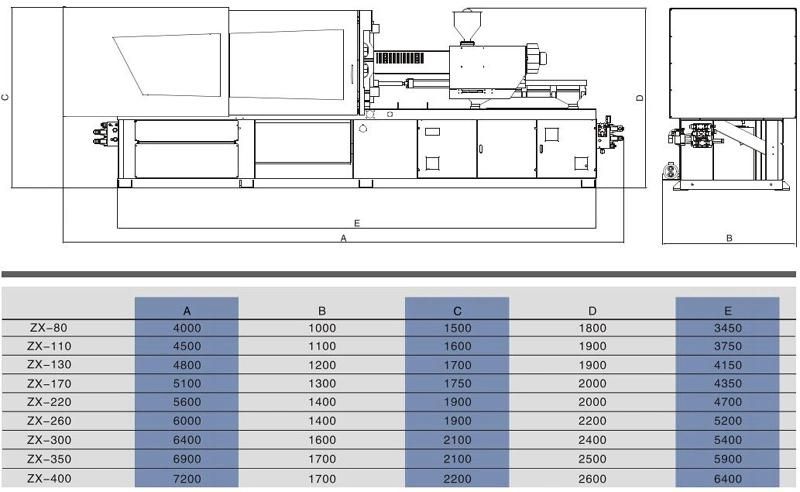

- Specification:4.8 x 1.2 x 1.9 M

- Trademark:HANPLAS, OEM

- Origin:China

- HS Code:8477101090

- Production Capacity:100PCS,Month

Description

3, Platen Dimension of Plastic Injection Molding Machine

4, Dimension of Plastic Injection Molding Machine

5, Technical Characteristics of Plastic Injection Molding Machine

CLAMPING SYSTEM  | -FEA designed double-toggle five-joint clamping machinery -High rigidity platen with enlarged space between tie-bar -Movable platen supported by the adjustable slide system which improves platen parallelism and life time of tie-bar and mould -Optimized lubrication system ensuring precision clamping and extending the life time of the clamping |

INJECTION SYSTEM  | -Double guide bracket structure, multipoint fixed ensure injection smoothly and accurately -High speed and high pressure adopt special injection design, improving injection speed -Injection cylinder, premold oil motor and plastic screw are in the same centreline, to enhance the injection pressure and injection speed, to achieve high precision, fast injection molding |

HYDRAULIC SYSTEM | -Adopt the imported pump, low noise, long lifetime, stable performance -High performance hydraulic valve, less failure, fast switch, convenient maintenance -Low pressure mould protect system, which is more suitable for the precision mould -Lubrication oil in dependent lubrication system can lubricate everywhere in the best situation |

6, Manufacturer of Plastic Injection Molding Machine

7, Contact Information

Contact Person: Mr. Tony

Comapny: Ningbo Zhen Yue Machinery Co.,Ltd.

Address: No.39, Lane 158, Huangcheng West Road, Ningbo, China.

Zip Code: 315012

Production: Plastic Injection Molding Machine

Remark:

1, the company reserves the right to revise all information (including word, photo) above.

2, due to technology development, the machine design or specification would be changed without any prior notice.

3, if you need CE machine, please tell us in advance of order. Otherwise, we provide normal machine (not CE machine). CE machine is special and expensive.