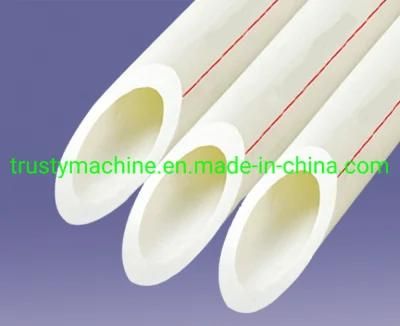

The Most Economic PPR Pipe Extrusion Line/ Pert Pipe Extrusion Line

QINGDAO TRUSTY PLASTIC MACHINERY CO., LTD.- Warranty:14 Months

- Product Type:PPR Pipe

- Screw No.:Single-screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

Base Info

- Model NO.:SJ-65; SJ-75; SJ-90

- Customized:Customized

- Condition:New

- After-sales Service:Oversea Installation&Debugging

- Length(M):30

- Height(M):3.5

- Converter:ABB

- Control System:PLC Control System

- Contactor:Siemens

- Motor:Siemens

- Transport Package:Wooden Packing

- Specification:Customized

- Trademark:Trusty

- Origin:Qingdao, China

- HS Code:84772090

- Production Capacity:20 Set,Month

Description

2.Product IntroductionPP-R pipe equipment is mainly used in the production of residential water supply systems, industrial water transportation, compressed air transportation, etc. In the history of international pipe development, PP-R is the latest product to be promoted. It is environmentally friendly, inexpensive, non-toxic, non-corrosive, high-temperature resistant, and easy to install.

The plastic pipe equipment is a new product developed by our company after introducing and absorbing foreign advanced technology. The key components such as screw and head are specially designed according to the characteristics of PP-R. The control electric appliance adopts frequency conversion speed regulation, and the main electric parts adopt imported famous brand products. The whole equipment has the characteristics of high output, stable quality, and small product error. It is the first-class equipment in today's plastic machine industry. At the same time, the equipment can be adapted to the production of PE, PP and other pipe materials. Our company provides process recipes and turnkey projects. This machine can also produce PE and PERT pipes at the same tim

3.Features

This production line is mainly used for the production of pipes with PP-R resin as raw material, and it is also suitable for the production of pipes with PE-RT, PB, and PE-X resin as raw materials.

1. Man-machine interface operation, high degree of automation.

2. It adopts special screw and has good plasticizing effect.

3. The composite spiral head is used to effectively clear the material memory.

4. Vacuum shaping and constant temperature control eliminate pipe stress.

5. The co-extrusion machine head is adopted, and the pipe color line is added.

6. Large extrusion volume, low melt temperature and uniform melt temperature.

7. A wide range of material processing.

4.Technical Parameter

6.FAQ

1.WHY CHOOSE US

We are the Professional manufacturer to develop the plastic extrusion machines in Qingdao. Machine quality and customer satisfaction is our pursuit.Be sure we have the strength to provide you with quality machines and perfect service.

2.WHAT SERVICES DO WE OFFER?

Pre-sale communication → Design proposal, signature confirmation→

Customized production→ Test machine before shipment →Package &

delivery→ Engineer installation→Training operator → Technical support

3.PAYMENT TERMS:

30% of total amount should be paid by T/T as down payment ,the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C by payment(at sight).

4.DELIVERY CONDITIONS:

4.1 Delivery condition: FOB Qingdao port or CIF destination Port.

4.2 Delivery terms: Within 30-60 working days after receipt of advanced payment, the seller should inform the buyer to do inspection,the seller should finish packing of goods and ready for shipment within 15 working days after the seller receipt the full payment.

5.WARRANTY TERMS

5.1 Warranty period: 12 months, starting from the machine receipt in customer's warehouse

5.2 Seller shall grant: services and spare parts, free-of-charge service throughout the entire equipment during warranty period.

5.3 long life service: the seller should provide long life service for the sold goods, the buyer pay for needed spare parts after the 12months warranty terms.

6.INSPECTION

When the machine finished, the seller should inform the buyer to do inspection before shipment, the seller guaranty good performance of all the sold goods.the seller undertake the material cost for the machine inspection in seller's factory. the buyer should come to seller's factory to do the inspection work, or the buyer could entrust any third party to come to seller's factory to do the inspection work.

7.INSTALLATION AND EQUIPMENT COMMISSIONING:

if the buyer requires, the seller should send technician team to buyer's factory for installation and testing the whole line, and the buyer should undertake the whole food/place and round tickets (airplane, food, hotel, and so on), and pay salary to engineer for 100 usd/day/engineer.