Pet Making Injection Molding Machine

Ningbo Haijiang Machinery Manufacturing Co., Ltd.- After-sales Service:Online Service

- Warranty:Online Service

- Type:Preform Injection

- Structure:Horizontal

- Plastic Type:Thermoplastic

- Plasticizing Way:Plunger Type

Base Info

- Model NO.:HJF240

- Clamping Way:Mechanical

- Automation:Automatic

- Computerized:Computerized

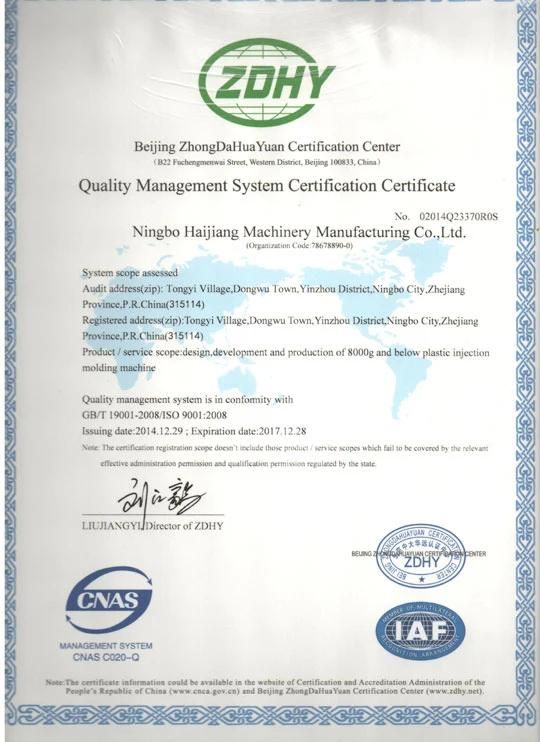

- Certification:CE, ISO9001:2008

- Usage:Electric Parts

- Clamping Force:3600kn

- Injection Pressure:160MPa

- Pump Motor Power:37kw

- Oil Tank Capacity:620L

- machinery Dimensions(mm):6.3m*1.9m*2.4m

- Transport Package:Standard Export Package for Injection Machine

- Trademark:HJF--HAIJIA

- Origin:China

- HS Code:8477101090

Description

Servo Controller Part:

1.) High Precise Control The servo system can control the machine's pressure, speed & location precisely, make sure that the error of accurate repeatability precision for the shot measurement is <0.3%

2.) High sensitive response Because the motor vector is matched with the controller accurately, it only takes 0.5sec. inputing the number from 0 to max. Compared with other traditional hydraulic injection molding machine, HJS series is more faster in speed with shorter cycle time and high efficient in production

3.) Low noise Compared with traditional fixed pump & variable pump system, the noise is 1/10 lower under normal circumstance, more suitable for sealed dustless workshop

4.) Energy Saving Overall efficiency is 10% more & driving capacity is 18% more than common machine. This series can save 40-80% energy, and achieve first-class energy efficency

5.) Water cooling saving The system condition prevent high pressure uploading without any power output, leads to the water cooling saving

2. injection molding machine certification

Tel:+86 13777071647

Http://cnhaijiang.en.made-in-china.com

Ningbo Haijiang Machinery Manufacturing Co.,Ltd.

Address:Next to the treasure Bringing the road, Yinzhou District, Ningbo (Tong Industrial Zone)