PP PE PC PS ABS HDPE LDPE Plastic Recycling Noodle Making Machine

Zhangjiagang Boxin Machinery Co., Ltd.- After-sales Service:Can Be Debugged Abroad

- Warranty:One Year

- Type:Sheet Extruder

- Plastic Processed:Polystyrene

- Product Type:Granulating Extruder

- Feeding Mode:One Feed

Base Info

- Assembly Structure:Integral Type Extruder

- Screw:Single-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Model No:Type-70

- Motor Brand:Siemens, ABB or Chinese Best Brand

- Bearing Brand:SKF and NSK

- Hot Washing Tank:Included

- Invertor Brand:ABB or Teco

- Guarantee/Warranty:13 Monthes

- Capacity Range:90-1200kg,H

- Color:Optional

- Weight:3-20t

- Machine Material:304 Stainless Steel

- Belong:Plastic Granulator

- Object:Plastic Pelletizing Machine

- Name:Plastic Noodle Making Machine

- Transport Package:Nude and Wood Packing

- Specification:According to the actual requirement to configure

- Trademark:Boxin brand

- Origin:China Manufacture for HDPE Pelletizing Machine

- HS Code:8477800000

- Production Capacity:60 Sets,Year

Description

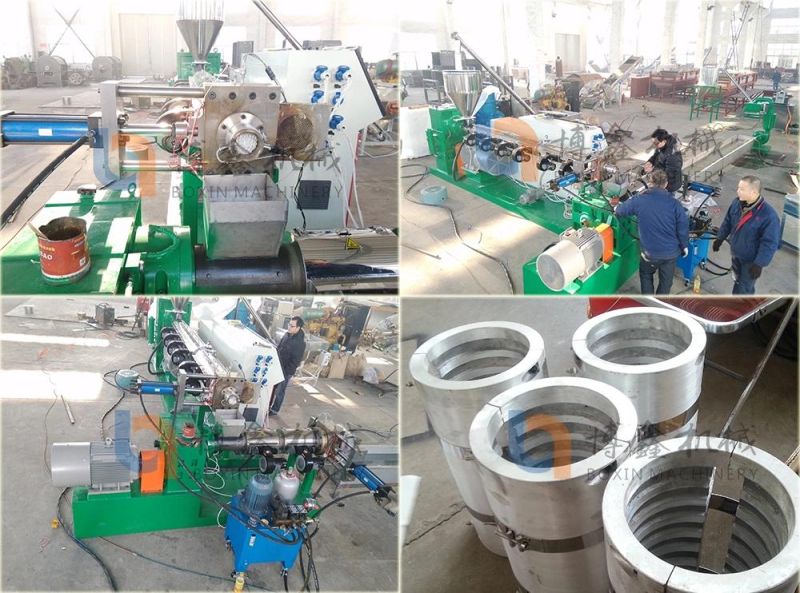

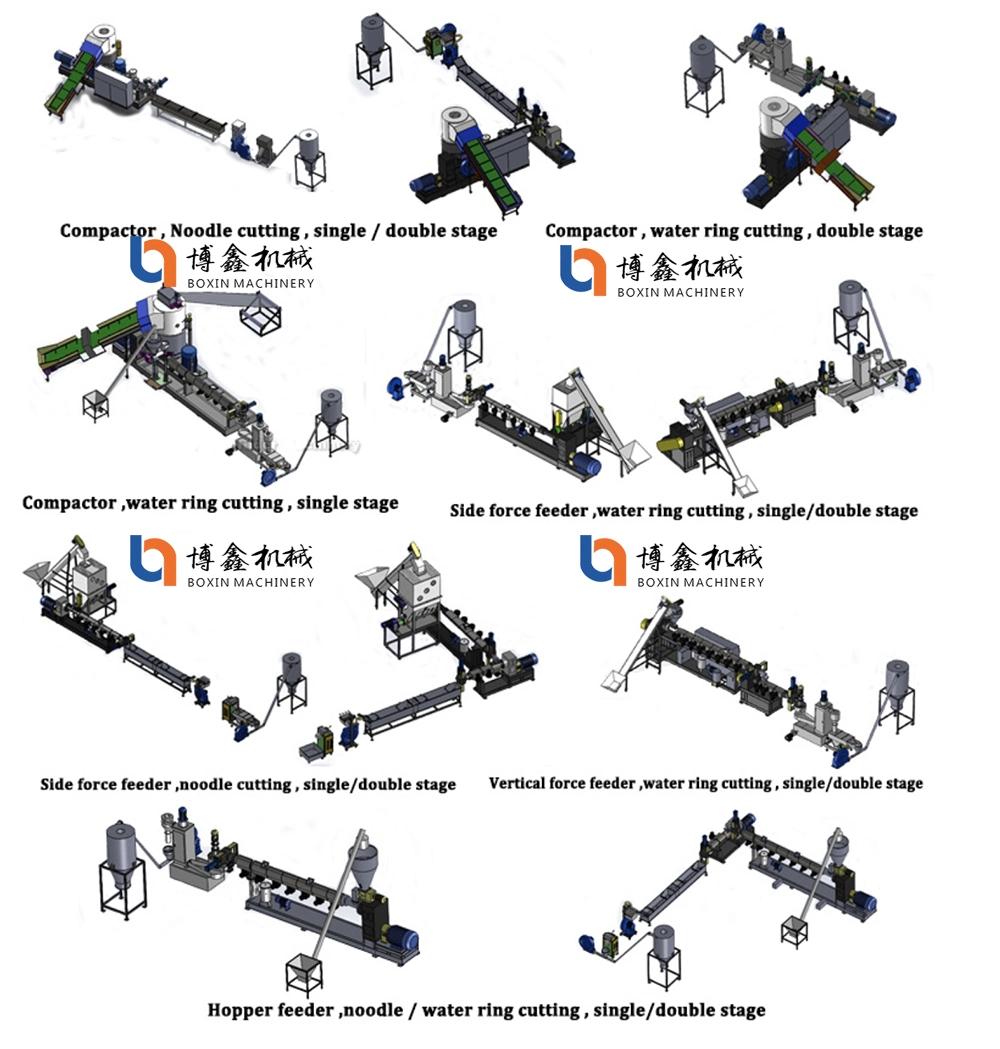

Main introduction of HDPE PP PE PC PS ABS LDPE Plastic recycling Noodle Making Machine:

Plastic pelletizing machine is used to recycle various kinds of plastic products and make plastic into granules to recover the plastic and suit for making products again.

Advantage of PE pelletizing machine:

1. For the most important screw, each screw is designed by the engineer according to the characteristics of the plastic and the output. To get more better plasticizing effect, reducing waste of materials and electricity.

2.The raw material of the screw is 38CrMoAl, which has strong wear resistance and long service life, reducing the wear of the screw.

3.High quality and drive equipment (Siemens beide Motor, 3 live wires and 1 netutral wire ) makes the equipment safer and more reliable in use.

4.In generally ,the screw can be used for 3-4 years, produced 2000-3000 tons of pellets.

Single stage Main Technical Parameter of PE noodle making Machine:

| Model | STSJ90 | STSJ 100 | SJ120 | STSJ130 | STSJ160 | STSJ180 |

| Screw Dia. | 90 | 100 | 120 | 130 | 160 | 180 |

| L/D Ratio | 33:1 | 33:1 | 33:1 | 33:1 | 33:1 | 33:1 |

| Capacity (kg/h) | 150-200 | 200-250 | 250-350 | 450-550 | 650-800 | 800-1000 |

| Main Motor Power(kw) | 55 | 75 | 90 | 132 | 160 | 250 |

| Total Electric Power(kw) | 110 | 135 | 160 | 215 | 263 | 375 |

Double stage Main Technical Parameter:

| Model | STSJ90/90 | STSJ100/100 | STSJ120/120 | STSJ130/130 | STSJ160/160 | STSJ180/200 |

| Screw Dia. | 90 | 100 | 120 | 130 | 160 | 180 |

| L/D Ratio | 28:1/10:1 | 28:1/10:1 | 28:1/10:1 | 28:1/10:1 | 28:1/10:1 | 28:1/10:1 |

| Capacity (kg/h) | 150-200 | 200-250 | 250-350 | 450-550 | 650-800 | 800-1000 |

| First Stage Motor (kw) | 55 | 75 | 90 | 132 | 160 | 250 |

| Second Stage Motor(kw) | 22 | 30 | 37 | 45 | 55 | 75 |

| Total Electric Power(kw) | 150 | 185 | 220 | 285 | 350 | 490 |

Machine Process:

If you want to know more information, feel free to contact.

If you want to know more information, feel free to contact.