WPC Door Making Machine / WPC Door Frame Extrusion Line

QINGDAO DING KUN PLASTIC MACHINERY CO., LTD.- Warranty:1 Year

- Product Type:WPC Profile

Base Info

- Model NO.:SJSZ65,132

- Screw:Double-Screw

- Automation:Automatic

- Computerized:Non-Computerized

- Certification:CE, ISO9001:2008

- Customized:Customized

- Plastic Machine:WPC Solid Door Frame Machine

- Raw Material:WPC

- Output Capacity:150-240 Kg, Hr

- Production Line Speed:1-5m,Min

- Total Installed Power:90kw

- Actual Energy Consumption Power:About 70kw

- Overall Dimension:About 22m*1.6m*2.6m

- Gross Weight:About 10t

- Operator:1-2 Persons Per Shift

- Power Supply:380V 3phase 50Hz or as Your Demand

- Motor:Siemens

- Inverter:ABB

- Temperature Meter:Omron

- Screw Design:Double Screw

- Control:Siemens PLC

- Transport Package:1. Mold Package: Wooden. 2. Outside: Stretch Film

- Specification:SJZ65,132

- Trademark:Dingkun

- Origin:Qingdao

- HS Code:8477209000

- Production Capacity:150-240 Kg, Hr

Description

1. It is designed for producing various size of plastic composite products,such as WPC profiles,WPC board,WPC decorate panel.Our WPC machine has features of low consumption,low noise,stable running..

2. This WPC machine include:extruder,mould,vacuum calibration table,haul-off machine,cutter and stacker.

3. The extruder of WPC machine adopt special wpc screw and barrel for extrusion.With different mould,WPC machine can produce wpc products with different shapes.

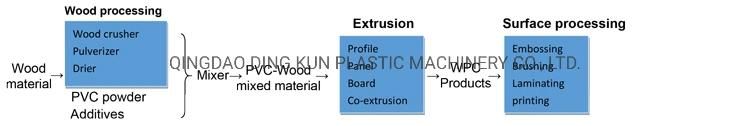

Flow Process

1.PE/PP WPC profile production flow

Wood milling(wood powder,rice husk)-- Mixer(plastic+wood powder)--Pelletizing machine--PE/PP-WPC extrusion line

2.PVC-WPC profile production flow

Wood milling(wood powder,rice husk)--Mixer(plastic+wood)--PVC-WPC extrusion line

Technical Parameter

Machine list

7.Electric control system

1.SJZ series conical twin screw extruder:

The specially designed screw and the advanced controlling system ensure excellent plasticization, high output and stable extruding.

2.Die mould:

Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips, and also differential action of up-down piece guarantee even thickness of the plate.

3.Vacuum calibration table:

Heating exchanging and cooling system of quick speed in calibrating system alternate effectively and ordinally with vacuum system, which ensures calibrating precision. Vacuum system composes two independent subsystems and each is equipped with several fixed circulating vacuum lines of three-point type. Meanwhile, each line carries vacuum regulating system and vacuum display system that realize even and stable vacuum degree of plate surface.

4.Haul-off unit & Cutter unit :

There are two tractors. The first one is of high powr, high reduction ratio, multi-roller type, well low-speed operation, high traction and is able to draw the plate up from the calibrating table evenly and synchronal. The second one is designed to remove stress, and in addition it is equipped with edge-cutting device to ensure the valid width and smooth cut of the edges. 5. Stacker

5. Stacker

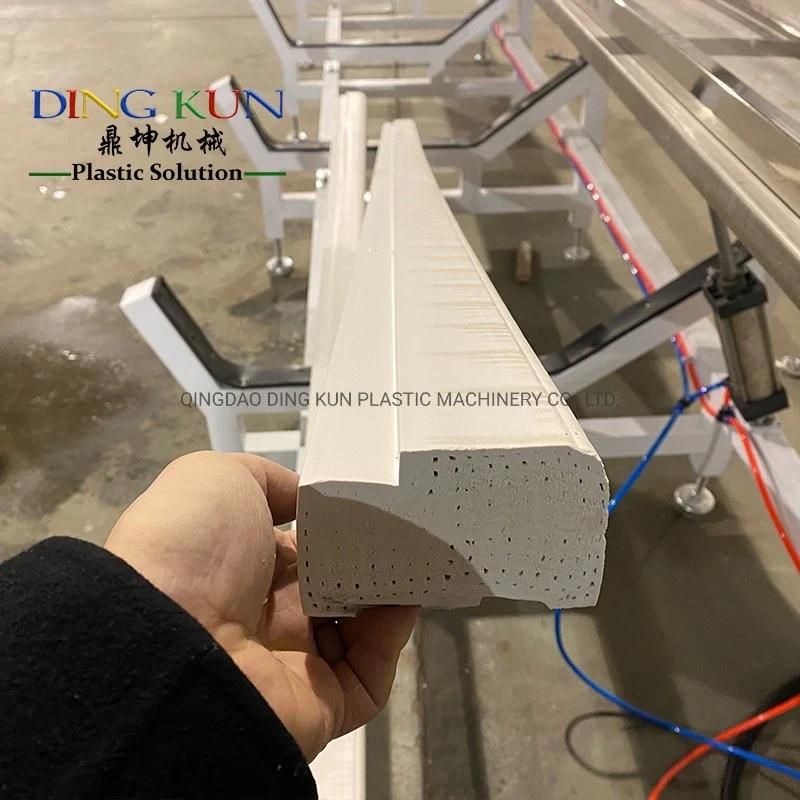

WPC Products - Produced by machine

Center Co., Ltd.,

CNAS

03413Q21640R1M

Single-Screw Plastic Extruders

and Conical Twin-Screw

Plastic Extruders

Certification

Company S.A.

SJ-30, SJ-45, SJ-65, SJ-90,

SJ-120, SJ-150, SJ-180,

SJ-200, SJSZ-51/105,

SJSZ-65/132, SJZS-80/156,

SJSZ-92/188

SGS-CSTC Standards Technical Services Co.,Ltd

Focus Technology Co., Ltd

FAQ

Q: Your company is an industrial manufacture factory or a transactional company ?

A: Deerma Company is an industry manufacture of Extrusion Machines.

Q:All of your products are made by your self or compacted via purchasing the others?

A: we have independent technical team who focus on design & development & Manufacture extrusion machines. all the products are made by our technical team.

Q:Annual Production Capacity( Previous Year)

A: About 80 lines from 2018.1 to 2019.12 and total revenue is about USD 2500000

Q: Quality Control Management

Q: Is there quality control on all production lines?

A: Yes, all production lines have adequate quality

control

Q:Do the QA/QC inspectors work independently from the production line?

A: Yes

Q:How many QA/QC inspectors in total?

A: 4

Execellent Service-Turnkey Project (Pre-Sale and After-Sale Service)

DINGKUN is committed to providing full support for its local and international clients and dealers and will always provide a prompt response to customer enquiries.

1. Provide all the machines for the complete production according to customer's requirements.

2. Provide complete service for factory layout and other information to help customer to build the factory.

3. Provide the raw material to the customer if need.

4. Provide good service for machine installation and training, until the customers can run the machines and make stable production.

5. Provide after-sell service for all the life, except one year quality guarantee,

6. Provide good quality, good price and good service to customer. We are the professional and trustable supplier for turnkey projects. Let us do win-win business together.

Why Choose us

1.We are China Leading Plastic Machine Manufacturer.

2.Alibaba Assessed 7 years Domestic Supplier .

3.Inspected by the Inspection Institution of SGS Certification.

4.100% QC inspection Before Shipmeng.

5.Best Quality & Best Service with Competitive price.

We have SIX this production lines in our showroom for other customer , welcome to visit our factory