PVC Foam Profile Production Line, PVC Wood Plastic Profile Production Linepvc/Wood Plastic ...

Jiangsu Acemien Machinery Co., Ltd.- Product Type:PVC Profile

- Screw:Double-Screw

- Automation:Automatic

- Computerized:Computerized

- Certification:CE, ISO9001:2008

- Customized:Non-Customized

Base Info

- Screw Design:Double-Screw

- Automatic Grade:Fully Automatic

- Dimension(L*W*H):20mx2.5mx2.2m

- Inverter:ABB for Machine for Production

- Motor:Germany Siemens Motor

- Output:150-450 Kg,H

- Raw Material:PVC Powder+Wood Powder

- Power(W):37-132 Kw

- Weight:10t for Machine for Production

- Machine Type:PVC Plastic Profile Machine

- Transport Package:Export Standard Package

- Specification:SJZ65

- Trademark:ACEMIEN

- Origin:China

- HS Code:84778000

- Production Capacity:100set,Year

Description

Basic Info.

Screw Design Double-Screw Automatic Grade Fully Automatic Dimension(L*W*H) 20mx2.5mx2.2m Inverter ABB for Machine for Production Motor Germany Siemens Motor Output 150-450 Kg/H Raw Material PVC Powder+Wood Powder Power(W) 37-132 Kw Weight 10t for Machine for Production Machine Type PVC Plastic Profile Machine Transport Package Export Standard Package Specification SJZ65 Trademark ACEMIEN Origin China HS Code 84778000 Production Capacity 100set/YearProduct Description

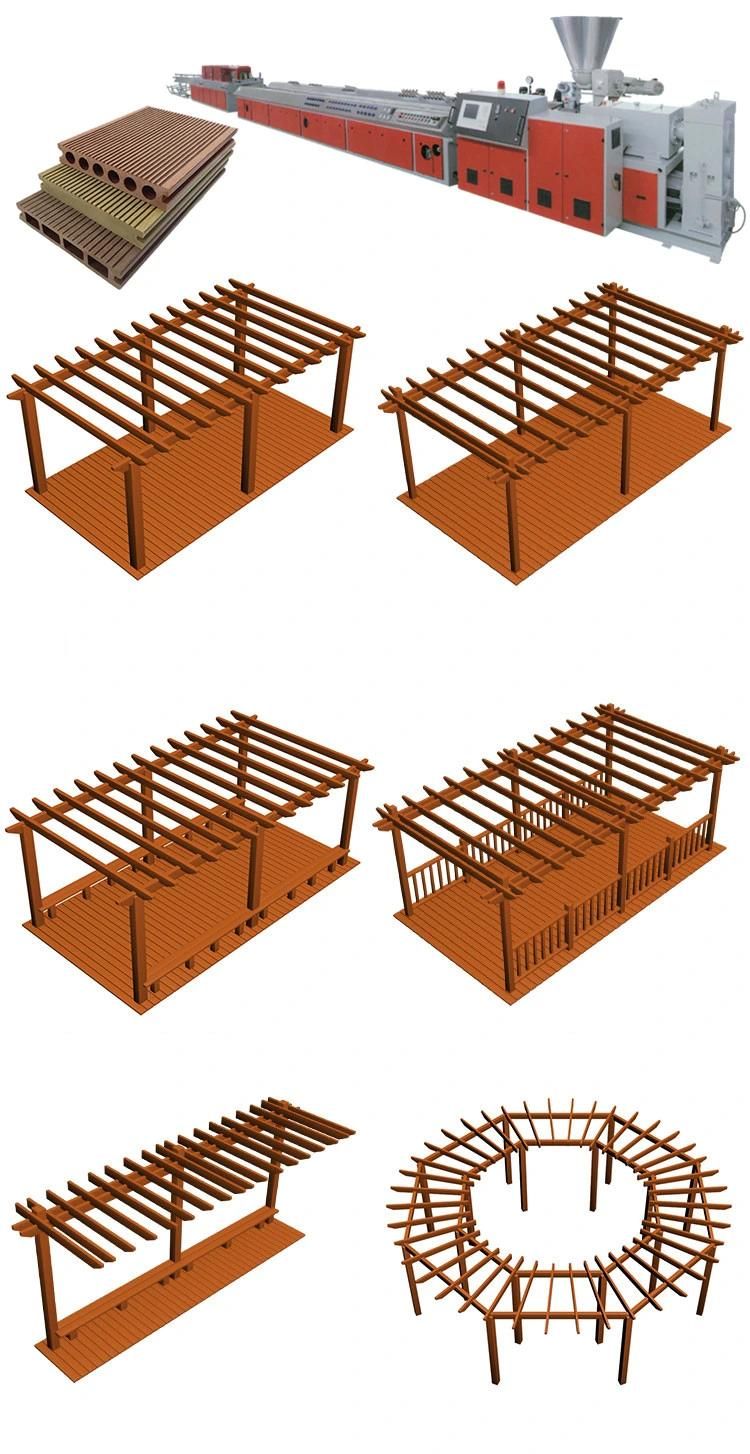

pvc foam profile production line,pvc wood plastic profile production linepvc/wood plastic profile extrusion line

Product Description

Product Description

PVC Ceiling Profile Production and extrusion Line

This machine is mainly used to produce PVC window & door profiles, PVC trunking profiles, PVC ceiling profiles, PVC panel, PVC board and so on. This PVC profile production line adopts advanced design concept to ensure the efficient extrusion of PVC material, combined with the unique concept of plasticization screw design to ensure uniformity of plastic extrusion, high capacity production.

Technical data

Model/data | Max width | Extruder model | Motor power | Max capacity |

| YF180 | 180mm | LSZ51/105 | 22kw | 120kg/h |

| YF240 | 300mm | LSZ65/132 | 37kw | 260kg/h |

| YF600 | 600mm | LSZ80/156 | 55kw | 400kg/h |

| YF800 | 800mm | LSZ92/188 | 90/100kw | 650kg/h |

Components of PVC profile production line

a. Conical twin screw extruder:

Using the high efficient conical twin screws, specially designed for PVC power to ensure uniformed plasticization, high extrusion. Stable temperature controlling system can guarantee high quality pipe extrusion.

b. Extrusion Mould:

Spiral type die head will ensure high speed extrusion and avoid the thermal decomposition of amorphous plastics and get high quality PVC profiles. There is heating control system inside of the mould, high efficient, easy to extrude. Bronze calibrators can make the PVC profiles fast calibrated and cooled.

c. Spraying and cooling table:

Rapid vacuum calibrating system allows the hot extruded PVC profiles to be cooled in a very short time and obtain the final size. Automatic temperature control system, pressure regulator, and vacuum control valve greatly enhance the sizing and cooling performance as well as the production speed.

d. Haul off machine:

Adopts caterpillar type suitable for different sizes of pipes. Haul off caterpillar blocks are made of abrasion resistant rubber material, which can make a high and stable hauling speed.

e. Cutting machine:

Precision machine cutter is able to make flat, straight cuts at high speed. A powerful suction device gathers up waste scraps after cutting, thereby making it easier for users to clean the cutter.

6. Stacking:

Automatic stacking with fixed length

Our Service

1. Turn key project

2. Technical documents

We will offer you all necessary documents, e.g. general layout plan, water scheme, electrical diagram and user manual after the contract is executed.

3.Arrangement for inspection, installation and testing work

We will inspect and test the machine in our factory first before shipping the machine. Customers are welcome to come and check the working machine, until the machine produces the exact products as customers requirements, and learn operation in our factory.

After the machine is delivered to customer's factory, we will send one or two technicians to customer's factory for on-site installation and commissioning of the whole machine line. Meanwhile, technicians will give free training lessons to workers in customer's factory.

4.The guarantee period of the whole machine is 12 months.

5.Technical support from our factory is free of charge for all the life; quick response to any questions from customers.

Why choose us:

1. Low cost : all the machines ,we make them by ourself to reduce the cost for our customers.

2. Genuine product with excellent quality : we choose our material very strict, all the material come to our factory must pass the quality test substandard goods are returned to the supplier.

3. Engerneers available to serve oversea.

4. Quick delivery: the company provide just in time delivery with its streamlined supply chain.

5. Cost saving: we take strong attention to every detail in the manufacturing process,the quality control in our factory is very strict, all defective semi-manufactures must be treated again or reject. all the machine must be checked out ,then deivered to our customer. all about that pushing up the price, what we want to do is give our customer a good quality product with stable working and long lived.

FAQ

1.Q: Are you an industry manufacture factory or a foreign trade company?

A: We are an industrial manufacture factory of plastic extrusion machinery and auxiliary equipment, which locates in Zhangjiagang city, China.

A: Loading Port: Shanghai by sea or by train.

2.Q: Payment term:

T/T, L/C, West Union, or Cash, etc.

3.Q: Do you have any other services for your products?

A: We have rich experience in manufacturing plastic machinery, so we can manufacture various machines according to customers' requirement.

4. Q:How do you make the quotation for clients?

A:The price depends on quality and performance but the clients should be satisfied first.