Plastic WPC / PVC / PE Wood Profile Fencing Wall Panel Extrusion Line Machine

QINGDAO TRUSTY PLASTIC MACHINERY CO., LTD.- After-sales Service:Installing in Customer′s Factory

- Warranty:14month

- Type:Profile Extruder

- Plastic Processed:PVC

- Product Type:Profile Extrusion Molding Machine

- Feeding Mode:Multiple Feed

Base Info

- Model NO.:SJSZ-65

- Assembly Structure:Separate Type Extruder

- Screw:Twin-Screw

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Product:WPC Profile Machine

- Model:Sjsz-51,65

- Capacity:150-250kg,H

- Motor Power:22,37kw

- Motor Brand:Siemens

- Actual Power:45kw

- Control System:PLC

- Line Speed:0.5-3m,Min

- Material:PVC Powder

- Length(M):18

- Width(M):2

- Height(M):3.5

- Contactor:Siemens

- Relay:Omron

- Weight:10t

- Transport Package:Wooden Packing

- Specification:Customized

- Trademark:Trusty

- Origin:Qingdao

- HS Code:84772090

- Production Capacity:200 Pieces,Year

Description

Basic Info.

Model NO. SJSZ-65 Assembly Structure Separate Type Extruder Screw Twin-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Product WPC Profile Machine Model Sjsz-51/65 Capacity 150-250kg/H Motor Power 22/37kw Motor Brand Siemens Actual Power 45kw Control System PLC Line Speed 0.5-3m/Min Material PVC Powder Length(M) 18 Width(M) 2 Height(M) 3.5 Contactor Siemens Relay Omron Weight 10t Transport Package Wooden Packing Specification Customized Trademark Trusty Origin Qingdao HS Code 84772090 Production Capacity 200 Pieces/YearProduct Description

Plastic WPC / PVC / PE Wood Profile Fencing Wall Panel Extrusion Line MachineAdvantage of our WPC / PVC / PE wood profile panel machines

1). Low consumption,low noise,stable running..

2) . WPC profile extrusion line machine including extruder,mould,vacuum calibration table,haul-off machine,cutter and stacker.

3).The extruder of WPC machine adopt special wpc screw and barrel for extrusion.With different mould,WPC machine

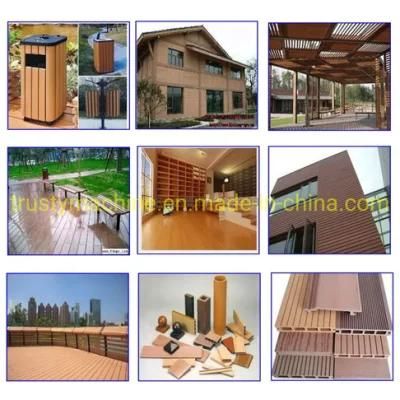

All kinds of WPC profile for flooring, wall, fencing can be produced with different moulds.

WPC / PVC wood profile extrusion line machine mainly for PVC+ wood powder to extrude wood-plastic panel such as integral door panel, building template, cabinet door, window board, wainscot, etc.

Machine List for Good Value WPC / plastic PVC / PE wood Profile Fencing Wall Panel Extrusion Line Machine

| Name | Quantity(set) |

| Mixer300/600 | 1 |

| Feeder | 1 |

| Twin screw extruder | 1 |

| Extruding mould | 1 |

| Customized mould | 1 |

| Calibration table | 1 |

| Haul off | 1 |

| Cutter | 1 |

| Stacker | 1 |

| Crusher | 1 |

| Mill | 1 |

| Model | SJSZ-65 |

| Total installation power(kw) | 155 |

| Transformer (kw) | 100 |

| Actual electricity consumption(kw) | 50 |

| Output (kgh) | 240 |

| Line speed (mmin) | 1-3 |

| Motor power(kw) | 37 |

Our company's main products are: WPC wood-plastic profile production line, PVC wall panel production line,PVC door and window profile production line, PVC/PE/PPR pipe production line, crust-foamed board production line, PE/PP/PC hollow sheet production line, PVC roof tile production line and PET packing belt production line, etc. According to customers' needs, to achieve diversified processing customization.

FAQ

FAQ1.WHY CHOOSE USWe are the Professional manufacturer to develop the plastic extrusion machines in Qingdao. Machine quality and customer satisfaction is our pursuit.Be sure we have the strength to provide you with quality machines and perfect service.

2.WHAT SERVICES DO WE OFFER?

Pre-sale communication → Design proposal, signature confirmation→

Customized production→ Test machine before shipment →Package &

delivery→ Engineer installation→Training operator → Technical support

3.PAYMENT TERMS:

30% of total amount should be paid by T/T as down payment ,the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C by payment(at sight).

4.DELIVERY CONDITIONS:

4.1 Delivery condition: FOB Qingdao port or CIF destination Port.

4.2 Delivery terms: Within 30-60 working days after receipt of advanced payment, the seller should inform the buyer to do inspection,the seller should finish packing of goods and ready for shipment within 15 working days after the seller receipt the full payment.

5.WARRANTY TERMS

5.1 Warranty period: 12 months, starting from the machine receipt in customer's warehouse

5.2 Seller shall grant: services and spare parts, free-of-charge service throughout the entire equipment during warranty period.

5.3 long life service: the seller should provide long life service for the sold goods, the buyer pay for needed spare parts after the 12months warranty terms.

6.INSPECTION

When the machine finished, the seller should inform the buyer to do inspection before shipment, the seller guaranty good performance of all the sold goods.the seller undertake the material cost for the machine inspection in seller's factory. the buyer should come to seller's factory to do the inspection work, or the buyer could entrust any third party to come to seller's factory to do the inspection work.

7.INSTALLATION AND EQUIPMENT COMMISSIONING:

if the buyer requires, the seller should send technician team to buyer's factory for installation and testing the whole line, and the buyer should undertake the whole food/place and round tickets (airplane, food, hotel, and so on), and pay salary to engineer for 100 usd/day/engineer.